Semi-flexible asphalt concrete interface phase fretting fatigue test device and method

A technology of asphalt concrete and fretting fatigue, which is applied in the direction of measuring device, using repeated force/pulsation force to test the strength and strength characteristics of materials, and can solve the problems of condensation or hardening, single loading direction of the interface, and unrealistic problems. Achieve the effect of accurate test results, wide application range and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

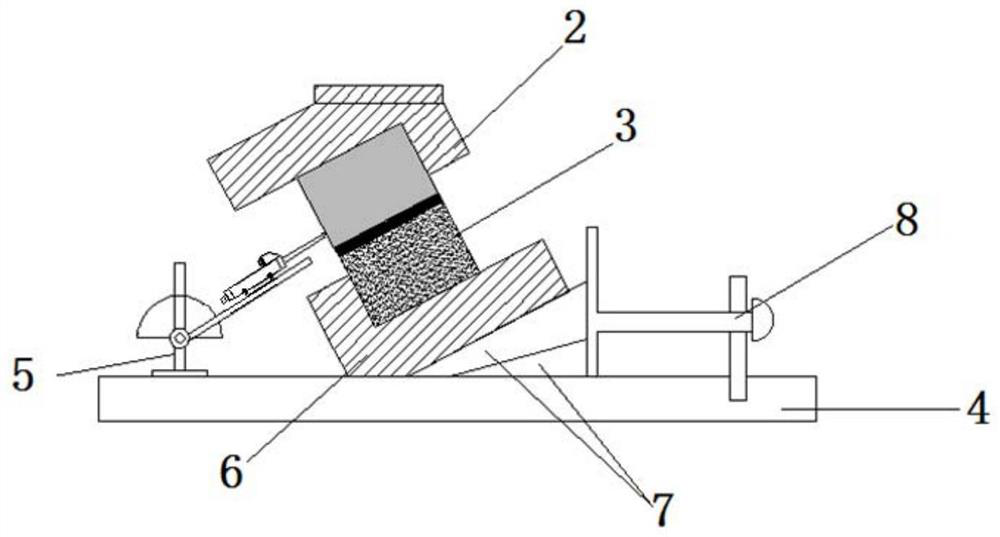

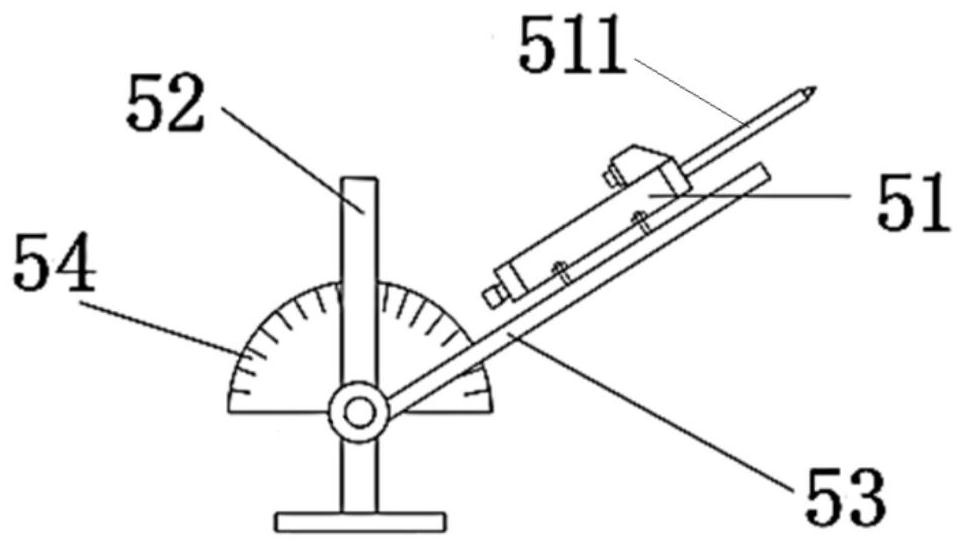

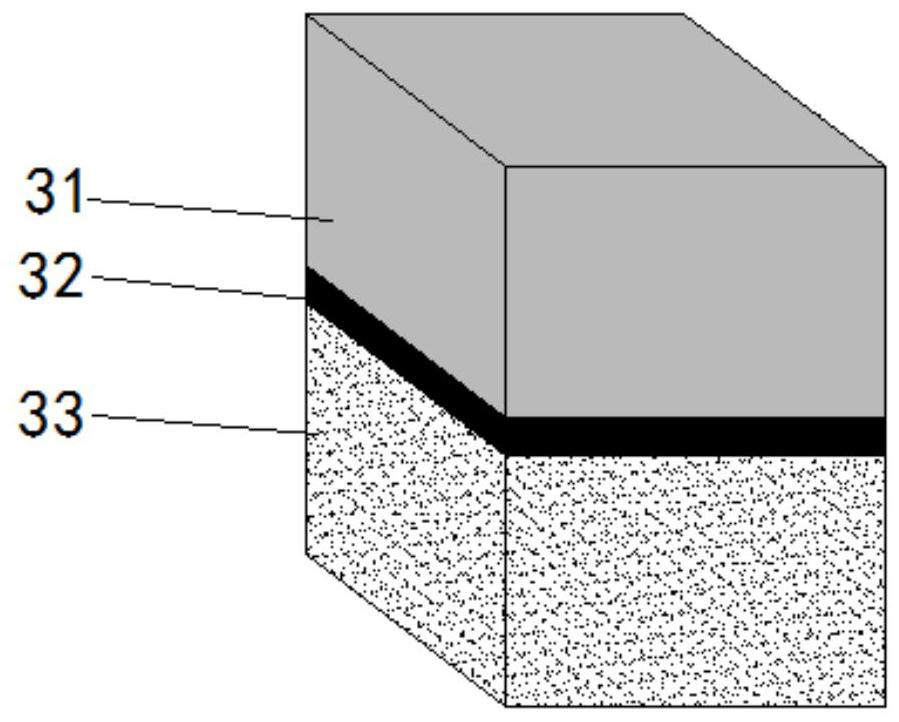

[0055] A semi-flexible asphalt concrete interface phase fretting fatigue test device is used for performing fatigue tests on a composite specimen 3. The composite specimen 3 includes cement blocks 31, asphalt 32 and stones 33 connected sequentially from top to bottom. The device is as follows: figure 1 and image 3 , including MTS testing machine, monitoring terminal, fixture and substrate 4, the fixture includes specimen upper mold and specimen lower mold 6, composite specimen 3 is sandwiched between specimen upper mold and specimen lower mold 6, and specimen lower mold 6 is obliquely arranged on the base plate 4 through the wedge 7, the base plate 4 is provided with a shear displacement measurement assembly 5 and a fixed stop 8, the wedge 7 is stuck between the fixed stop 8 and the lower mold 6 of the specimen, and the shear displacement measurement The component 5 includes a linear differential strain sensor 51, the sensing tip 511 of the linear differential strain sensor 5...

Embodiment 2

[0074] A kind of semi-flexible asphalt concrete interface phase fretting fatigue test method corresponding to Example 1, specifically:

[0075] Such as figure 1, set up the substrate 4, the lower mold 6 of the specimen, the composite specimen 3 and the upper mold 2 of the compression shear specimen in sequence, wherein the lower mold 6 of the specimen is bonded with the lower mold 6 of the specimen and the upper mold of the specimen through epoxy asphalt. Use wedges 7 with different inclination angles in combination to adjust the inclination angle of the lower mold 6 of the test piece, and at the same time make the wedges 7 close to the limit steel plate 81, and align the sensing tip 511 of the linear differential strain sensor 51 and the cement block 31 in the inclination direction The monitoring terminal displays the load value collected by the load sensor in the MTS testing machine and the displacement of the cement block 31 collected by the linear differential strain senso...

Embodiment 3

[0079] In this embodiment, when the load value displayed by the monitoring terminal drops suddenly, it is determined that the interface phase has been destroyed, and the test is ended, and the other is the same as in embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com