Production processing order wireless order picking method and system

A processing order and wireless technology, applied in the field of picking management, can solve the problems of high construction cost and construction cost, inconvenient equipment movement, weak system integrity, etc., and achieve the effects of reducing labor costs, low power consumption, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

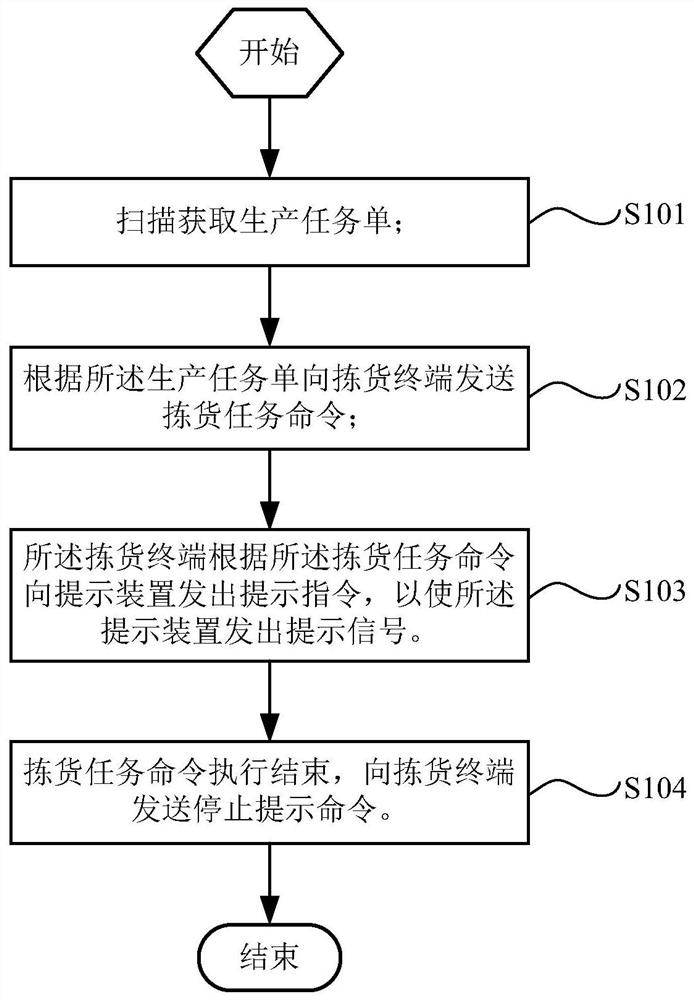

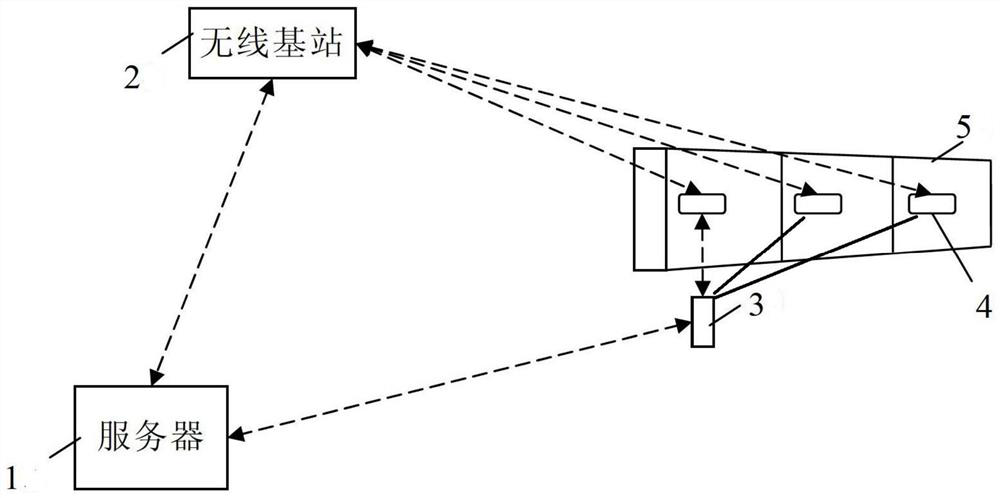

[0053] An embodiment of the present invention provides a wireless picking method for production and processing orders, which is applied to such as figure 2 In the shown production and processing order wireless picking device, the production and processing order wireless picking method may specifically include the following steps, such as figure 1 Shown:

[0054] S101, scan to obtain the production order;

[0055] S102, sending a picking task order to the picking terminal according to the production task;

[0056] In this embodiment, specifically, the material category, material quantity and container information of the production task list are counted, and the statistical results of the material category, material quantity and container information are displayed on the display screen;

[0057] According to the statistical results of the material category, material quantity and container information, the server sends a container lighting instruction to the wireless base stat...

Embodiment 2

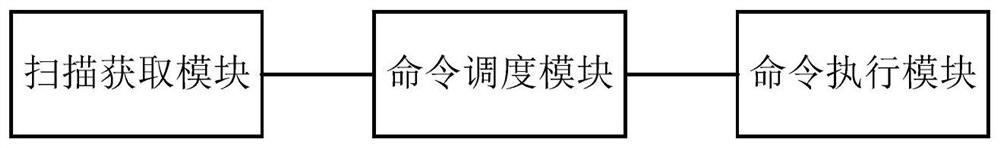

[0071] An embodiment of the present invention provides a wireless picking device for production and processing orders, such as image 3 As shown, the production and processing order wireless picking system can specifically include the following modules:

[0072] Scanning and obtaining module, used to scan and obtain the production order;

[0073] A command scheduling module, configured to send a picking task command to the picking terminal according to the production task;

[0074] In this embodiment, specifically, the material category, material quantity and container information of the production task list are counted, and the statistical results of the material category, material quantity and container information are displayed on the display screen;

[0075] According to the statistical results of the material category, material quantity and container information, the server sends a container lighting instruction to the wireless base station;

[0076] The wireless base s...

Embodiment 3

[0090] An embodiment of the present invention provides a wireless picking system for production and processing orders, such as Figure 4 As shown, the production and processing order wireless picking system can specifically include the following modules:

[0091] The communication bus is used to realize the connection and communication between the processor and the memory;

[0092] The memory is used to store computer programs; the memory may include a high-speed RAM memory, and may also include a non-volatile memory, such as at least one disk memory. The memory may optionally comprise at least one storage device.

[0093] A processor, configured to execute the above computer program to achieve the following steps:

[0094] S201, scan and obtain the production order;

[0095] S202. Send a picking task command to the picking terminal according to the production task;

[0096] In this embodiment, specifically, the material category, material quantity and container informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com