Solder wire externally provided with soldering flux coating and preparation method of solder wire

A solder wire and flux technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems of easy falling off of the flux coating, poor adhesion of the coating, easy falling off of the coating, etc. Excellent thermoplasticity, reducing the effect of empty welding and bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

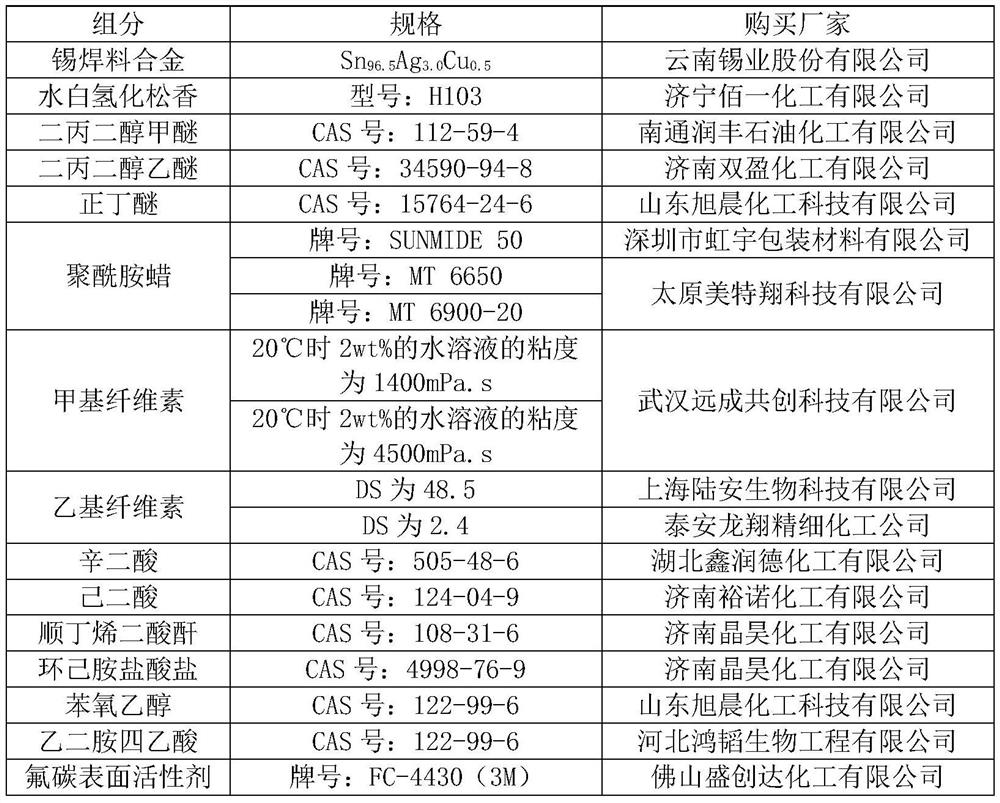

[0039] Embodiments 1-11 provide a method for preparing a solder wire with a flux coating on the outside, which will be described below by taking Embodiment 1 as an example.

[0040] A kind of preparation method of the solder wire with flux coating on the outside that embodiment 1 provides, its steps are:

[0041] (1) Sn 96.5 Ag 3.0 Cu 0.5 Put it into the extruder and set the parameters of the extruder: the temperature of the rosin barrel is set to 125°C, the temperature of the rosin conduit is set to 130°C, the temperature of the front beam of the extruder is set to 60°C, and the extrusion speed is set to 5 minutes per tin wire, to get a tin alloy wire with a diameter of 0.8mm, and take the quality of each tin alloy wire;

[0042] (2) Mix 6g of dipropylene glycol methyl ether, 3g of dipropylene glycol ethyl ether and 0.8g of n-butyl ether, heat to 65°C and keep it warm for 1h, then add 20g of polyamide wax SUNMIDE 50, stir evenly, and finally add 15g of methyl cellulose ( ...

Embodiment 2-4

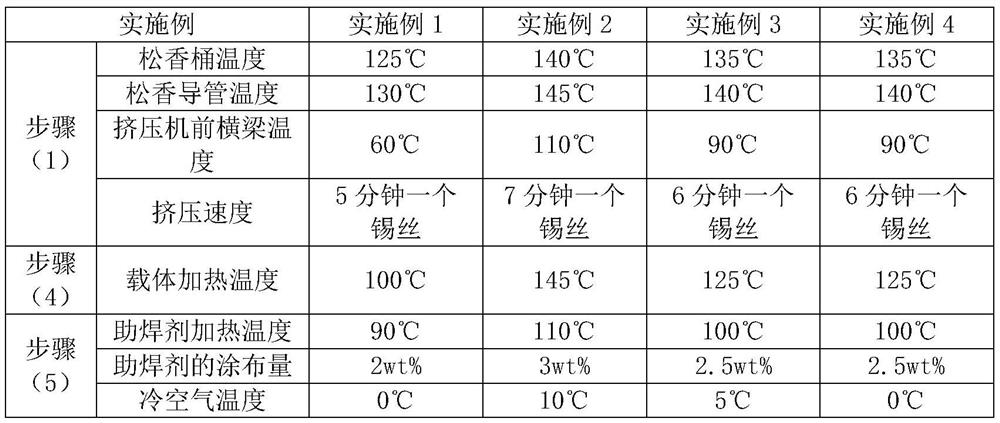

[0046] Examples 2-4 are the same as Example 1, except that the reaction parameters of each step are set differently, see Table 2 for details.

[0047] Table 2

[0048]

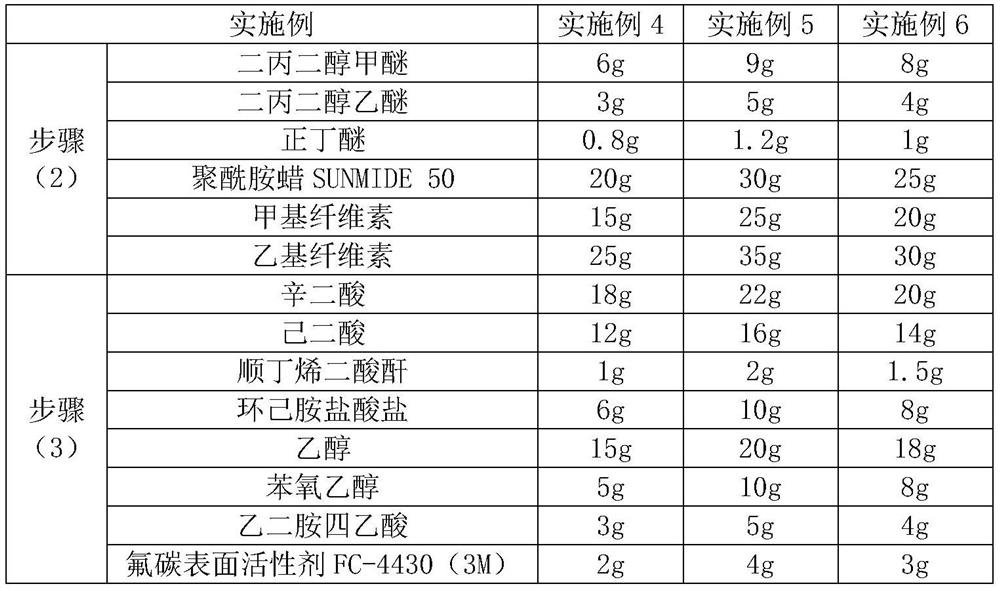

[0049] Examples 5-6 are the same as Example 4, except that the quality of raw materials in each step is different, see Table 3 for details.

[0050] table 3

[0051]

Embodiment 7

[0052] Embodiment 7, with embodiment 6, difference is only: the viscosity of described methylcellulose (2wt% aqueous solution when 20 ℃ is 1400mPa.s) is replaced by methylcellulose (2wt% aqueous solution when 20 ℃ The viscosity is 4500mPa.s).

[0053] Examples 8-10 are the same as Example 7, except that the composition of the polyamide wax is different, see Table 4 for details.

[0054] Table 4

[0055]

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com