Water treatment process for corn starch processing wastewater

A technology for processing wastewater and corn starch, which can be used in water/sewage treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc. It can solve problems such as anaerobic sludge poisoning and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

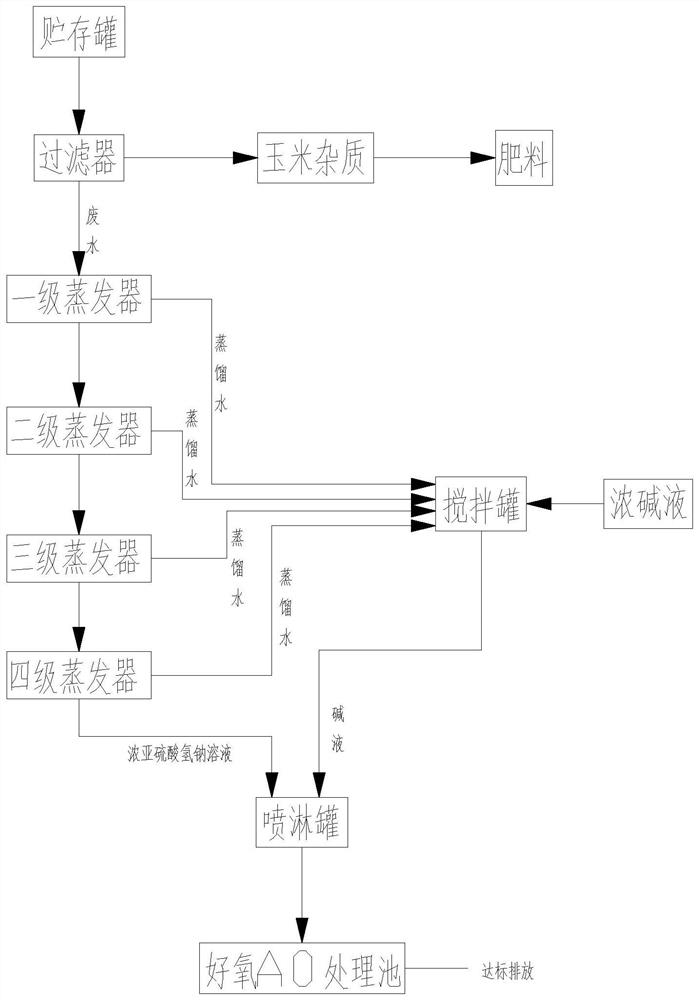

[0016] A kind of cornstarch processing wastewater water treatment process, such as figure 1 shown, including the following steps:

[0017] Step 1), inject the waste water mixed with sodium bisulfite produced by soaking corn into the storage tank for precipitation, then extract and transport to the filter through the pump body to separate the impurities from the waste water of sodium bisulfite, and obtain corn residue and sodium bisulfite respectively. Sodium bisulfate wastewater;

[0018] Step 2), the sodium bisulfite wastewater filtered in step 1) is input into a primary evaporator for high-temperature treatment, the moisture in the sodium bisulfite wastewater is exported by steam, and then the sodium bisulfite wastewater treated by the primary evaporator is The sodium bisulfate wastewater continues to enter the secondary evaporator, the third evaporator and the fourth evaporator for high-temperature treatment to obtain the concentrated sodium bisulfite solution separated fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com