Stable low-oil-permeability two-component heat-conducting gel and preparation method thereof

A two-component, stable technology, used in the field of thermally conductive gel, can solve the problems of glue overflow, oil separation, and the large difference in viscosity of A/B components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

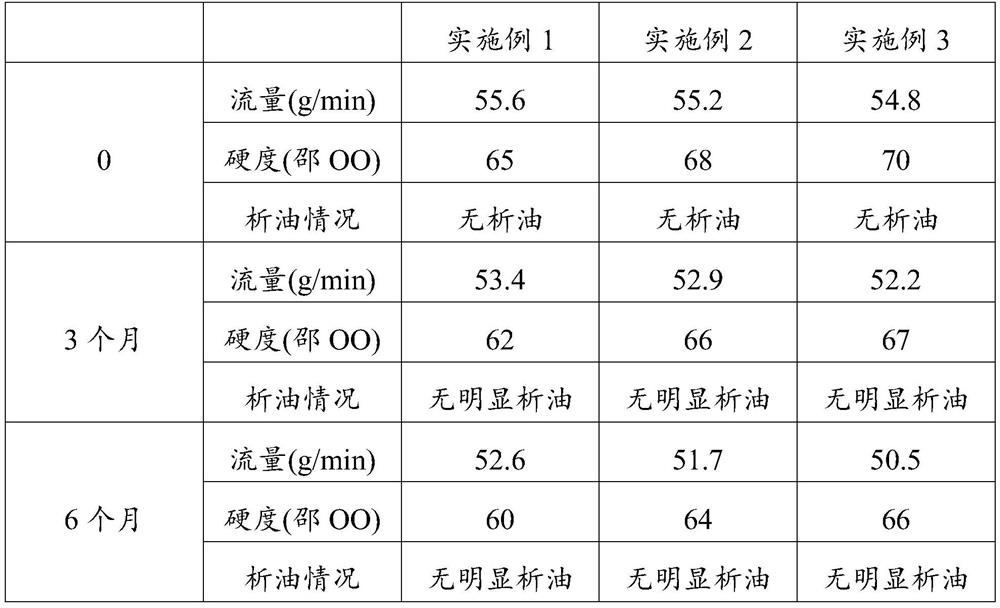

Embodiment 1

[0014] A method for preparing a stable low-permeation oil two-component thermally conductive gel, comprising the following steps:

[0015] 1) Preparation of component A

[0016] Add 10 parts of dimethyl silicone oil, 5 parts of vinyl silicone oil, 2 parts of coupling agent mixture, 1 part of blue color paste, 0.3 parts of defoamer, and 0.5 parts of platinum catalyst into the stirring tank and stir for 0.5 hours at a speed of 30 -35rpm, add 200 parts of 1-5μm spherical alumina and stir for 0.5h at a speed of 10-15rpm, add 400 parts of 40-50μm spherical alumina and stir for 0.5h at a speed of 10-15rpm, add 70-80μm spherical aluminum nitride 50 parts, stirred for 0.5h, the speed is 5-10rpm, add 1 part of capsule-type platinum catalyst, stir for 0.5h, the speed is 5-100rpm, press the mixture out with a pressure plate, the diameter of the pressure plate and the diameter of the discharge port are controlled at 25 : 1, the length of the discharge port is 10cm, put it into the stirre...

Embodiment 2

[0020] A method for preparing a stable low-permeation oil two-component thermally conductive gel, comprising the following steps:

[0021] 1) Preparation of component A

[0022] Add 10 parts of dimethyl silicone oil, 8 parts of vinyl silicone oil, 5 parts of coupling agent mixture, 1 part of blue color paste, 0.5 parts of defoamer, and 0.8 parts of platinum catalyst into the stirring tank and stir for 0.5 hours at a speed of 30 -35rpm, add 300 parts of 1-5μm spherical alumina and stir for 0.5h at 10-15rpm, add 500 parts of 40-50μm spherical alumina and stir for 0.5h at 10-15rpm, add 70-80μm spherical aluminum nitride 80 parts, stirred for 0.5h, the speed is 5-10rpm, add 2 parts of capsule-type platinum catalyst, stir for 0.5h, the speed is 5-100rpm, press the mixture out with the pressure plate, the diameter of the pressure plate and the diameter of the discharge port are controlled at 25 : 1, the length of the discharge port is 10cm, put it into the stirred tank again, vacuu...

Embodiment 3

[0026] A method for preparing a stable low-permeation oil two-component thermally conductive gel, comprising the following steps:

[0027] 1) Preparation of component A

[0028] Add 10 parts of dimethyl silicone oil, 6 parts of vinyl silicone oil, 4 parts of coupling agent mixture, 1 part of blue color paste, 0.4 parts of defoamer, and 0.7 parts of platinum catalyst into the stirring tank and stir for 0.5 hours at a speed of 30 -35rpm, add 250 parts of 1-5μm spherical alumina and stir for 0.5h at a speed of 10-15rpm, add 450 parts of 40-50μm spherical alumina and stir for 0.5h at a speed of 10-15rpm, add 70-80μm spherical aluminum nitride 65 parts, stirred for 0.5h, the rotating speed is 5-10rpm, add 1.5 parts of capsule-type platinum catalyst, stir for 0.5h, the rotating speed is 5-100rpm, press the mixture out with the pressure plate, the diameter of the pressure plate and the diameter of the discharge port are controlled at 25 : 1, the length of the discharge port is 10cm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com