Modifier for improving morphology of manganese sulfide in steel and preparation and use method thereof

A modifier, manganese sulfide technology, applied in the field of iron and steel metallurgy, can solve the problems of refining slag adsorption, reduce and control the effect of sulfide in steel, and achieve the effects of refining grains, improving anisotropy, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

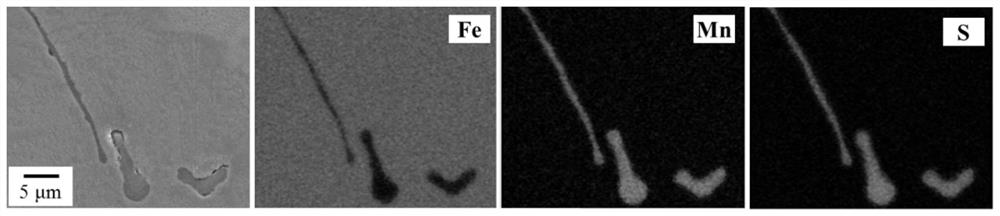

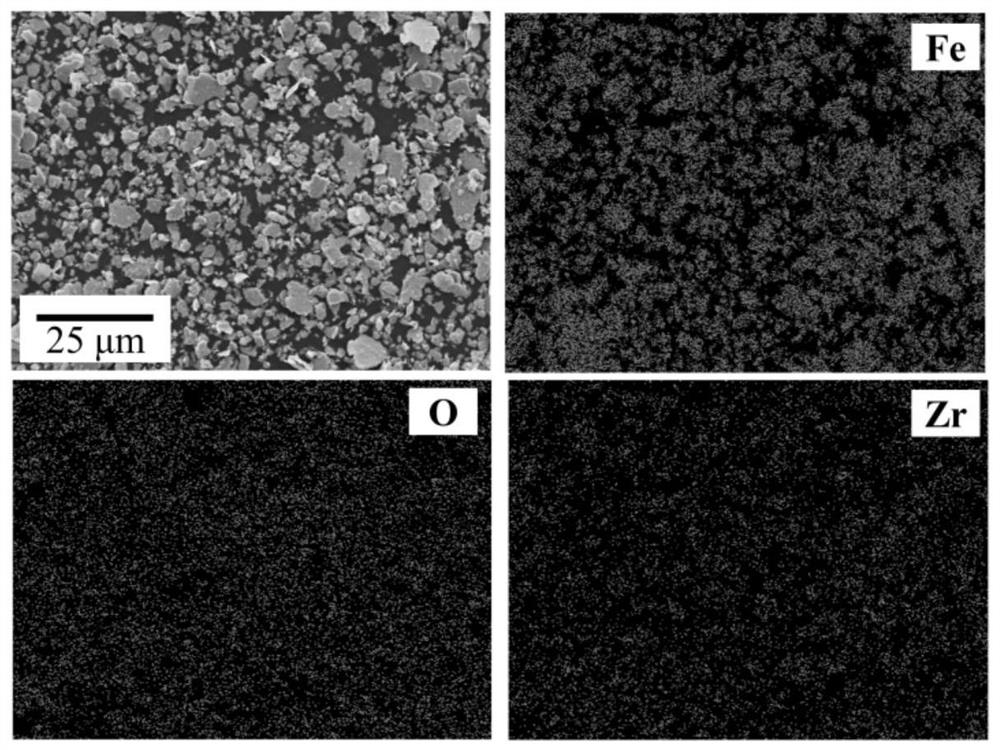

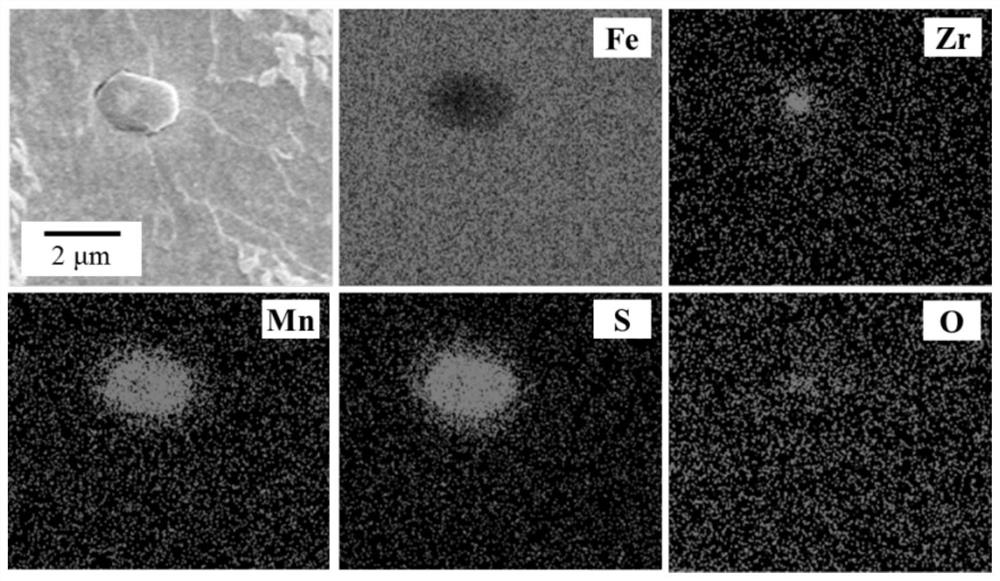

Image

Examples

Embodiment 1

[0040] A preparation method of a modifier for improving the morphology of manganese sulfide in steel, comprising the steps of:

[0041] (1) Nanoscale ZrO 2 , micron-sized iron powder and dehydroxylation solvent are added to the ball mill for high-energy ball milling pre-dispersion, the ZrO 2 , the addition ratio of iron powder and dehydration solvent is, ZrO 2 : iron powder: dehydroxylation solvent=1g: 10g: 20ml; the high energy ball milling time is 8 hours, and the high energy ball milling speed is 800r / min; the dehydroxylation solvent is ethanol and propanol mixed solvent with a volume ratio of 1:1 ; Raw material ZrO 2 The particle size is 150nm, and the iron powder particle size is 5.0μm;

[0042] (2) Perform crystallization treatment on the reagent obtained after step (1) high-energy ball mill pre-dispersion in a vacuum drying oven, the vacuum degree of the drying oven is figure 2 shown;

[0043] (3) The powder obtained in step (2) is subjected to molding processing b...

Embodiment 2

[0050] A preparation method of a modifier for improving the morphology of manganese sulfide in steel, comprising the steps of:

[0051] (1) Nanoscale ZrO 2 , micron-sized iron powder and dehydroxylation solvent ethanol are added to the ball mill for high-energy ball milling pre-dispersion, and the ZrO 2 , the addition ratio of iron powder and dehydration solvent ethanol is, ZrO 2 : Iron powder: ethanol=1g: 5g: 12ml; The high-energy ball milling time is 15 hours, and the high-energy ball milling speed is 400r / min; Raw material ZrO 2 The particle size is 250nm, and the iron powder particle size is 20.0μm;

[0052] (2) Perform crystallization treatment on the reagent obtained after step (1) high-energy ball mill pre-dispersion in a vacuum drying oven, the vacuum degree of the drying oven is <100Pa, the drying temperature is 50°C, and the drying time is 10 hours to obtain dry crystallized powder ;

[0053] (3) The powder obtained in step (2) is subjected to molding treatment, ...

Embodiment 3

[0060] A preparation method of a modifier for improving the morphology of manganese sulfide in steel, comprising the steps of:

[0061] (1) Nanoscale ZrO 2 , micron-sized iron powder and dehydration solvent methanol are added to the ball mill for high-energy ball milling pre-dispersion, and the ZrO 2 , the addition ratio of iron powder and methanol for dehydration solvent is, ZrO 2 : iron powder: methanol=1g: 8g: 15ml; the high energy ball milling time is 12 hours, and the high energy ball milling speed is 600r / min; raw material ZrO 2 The particle size is 200nm, and the particle size of micron iron powder is 10.0μm;

[0062] (2) Perform crystallization treatment on the reagent obtained after step (1) high-energy ball mill pre-dispersion in a vacuum drying oven, the vacuum degree of the drying oven is <100Pa, the drying temperature is 45°C, and the drying time is 10 hours to obtain dry crystallized powder ;

[0063] (3) The powder obtained in step (2) is subjected to moldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com