Finishing process of skin-friendly antibacterial fabric

An antibacterial fabric and process technology, applied in the finishing process of skin-friendly antibacterial fabrics, can solve the problems of poor washability and poor wearing comfort, achieve excellent antibacterial effect, improve cloth stiffness, and shorten the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

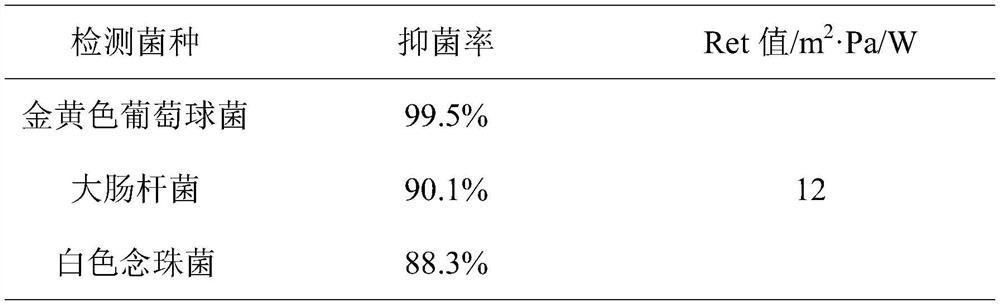

Embodiment 1

[0050] The finishing process of a skin-friendly and antibacterial fabric of the present invention is specifically implemented according to the following steps:

[0051] Step 1, the polyester-cotton fabric is pretreated by plasma treatment technology;

[0052] The plasma treatment pressure is 100Pa, the treatment time is 3min, and the treatment power is 15W;

[0053] Step 2, weigh raw materials according to the following formula, the mass percentage of each component is, polysaccharide-nano antibacterial hydrogel skin-friendly antibacterial composite finishing agent: 5%; ammonium chloride: 2%; softener SG-6: 3%, The balance is water, and the sum of the mass percentages of the above ingredients is 100%; the raw materials are mixed and stirred evenly; the stirring time is 1h, the stirring temperature is 50°C, and the stirring speed is 120r / min;

[0054] The preparation process of the polysaccharide-nano antibacterial hydrogel skin-friendly antibacterial composite finishing agent...

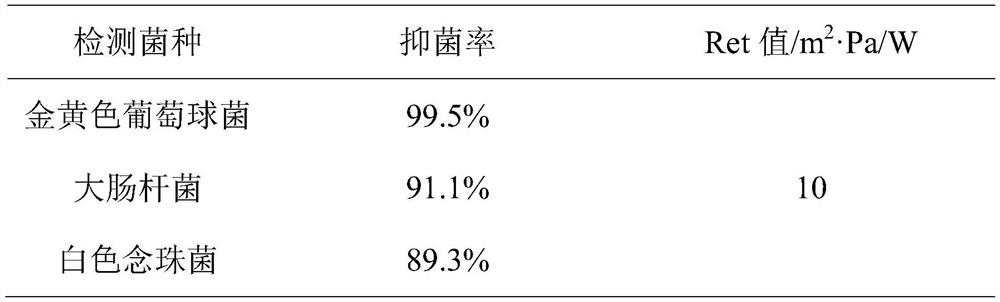

Embodiment 2

[0069] The finishing process of a skin-friendly and antibacterial fabric of the present invention is specifically implemented according to the following steps:

[0070] Step 1, using plasma treatment technology to pretreat the pure cotton fabric;

[0071] The plasma treatment pressure is 150Pa, the treatment time is 5min, and the treatment power is 20W.

[0072] Step 2, weigh the raw materials according to the following formula, the mass percentage of each component is, polysaccharide-nano antibacterial hydrogel skin-friendly antibacterial composite finishing agent: 4%; ammonium sulfate: 3%; softener SG-6: 4%, remaining The amount is water, and the sum of the mass percentages of the above ingredients is 100%; the raw materials are mixed and stirred evenly; the stirring time is 2.0h, the stirring temperature is 60°C, and the stirring speed is 120r / min.

[0073] The preparation process of the polysaccharide-nano antibacterial hydrogel skin-friendly antibacterial composite finis...

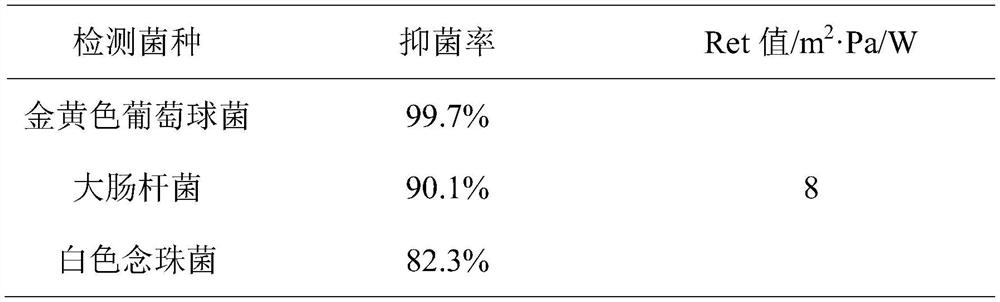

Embodiment 3

[0088] The finishing process of a skin-friendly and antibacterial fabric of the present invention is specifically implemented according to the following steps:

[0089] Step 1, the silk fabric is pretreated by plasma treatment technology;

[0090] The plasma treatment pressure is 200Pa, the treatment time is 3min, and the treatment power is 25W.

[0091] Step 2, weigh raw materials according to the following formula, the mass percentage of each component is, polysaccharide-nano antibacterial hydrogel skin-friendly antibacterial composite finishing agent: 5%; ammonium bicarbonate: 4%; softening agent 4%, the balance is water , the sum of the mass percentages of the above components is 100%; the raw materials are mixed and stirred evenly; the stirring time is 2.0 h, the stirring temperature is 70° C., and the stirring speed is 140 r / min.

[0092] The preparation process of the polysaccharide-nano antibacterial hydrogel skin-friendly antibacterial composite finishing agent is sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com