Mobile phone battery size and appearance defect detection system and detection method

A technology for mobile phone batteries and appearance defects. It is applied in the direction of optical testing for flaws/defects, measuring devices, and material analysis through optical means. It can solve problems such as time-consuming and labor-intensive, inability to directly reflect the overall situation of the product, and measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

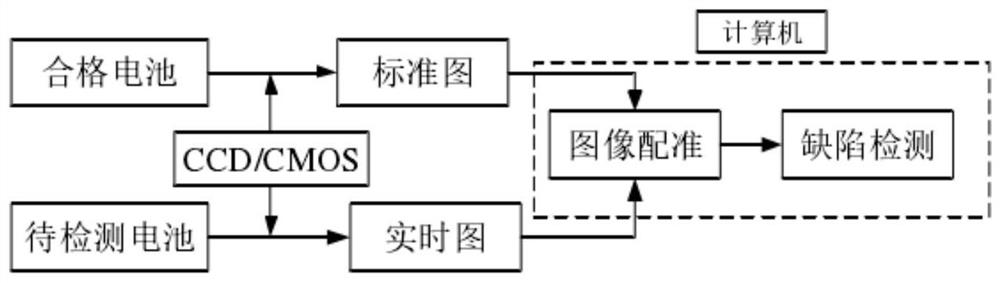

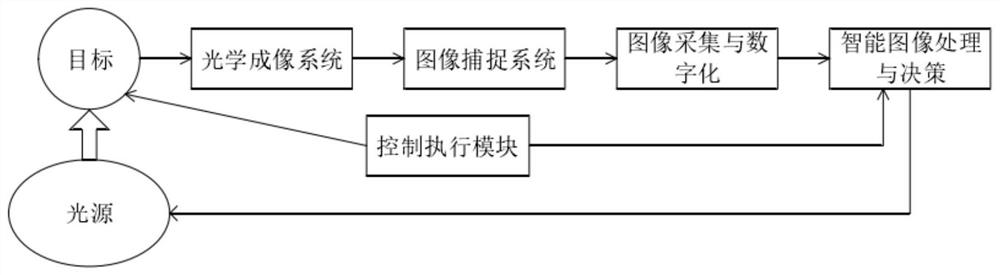

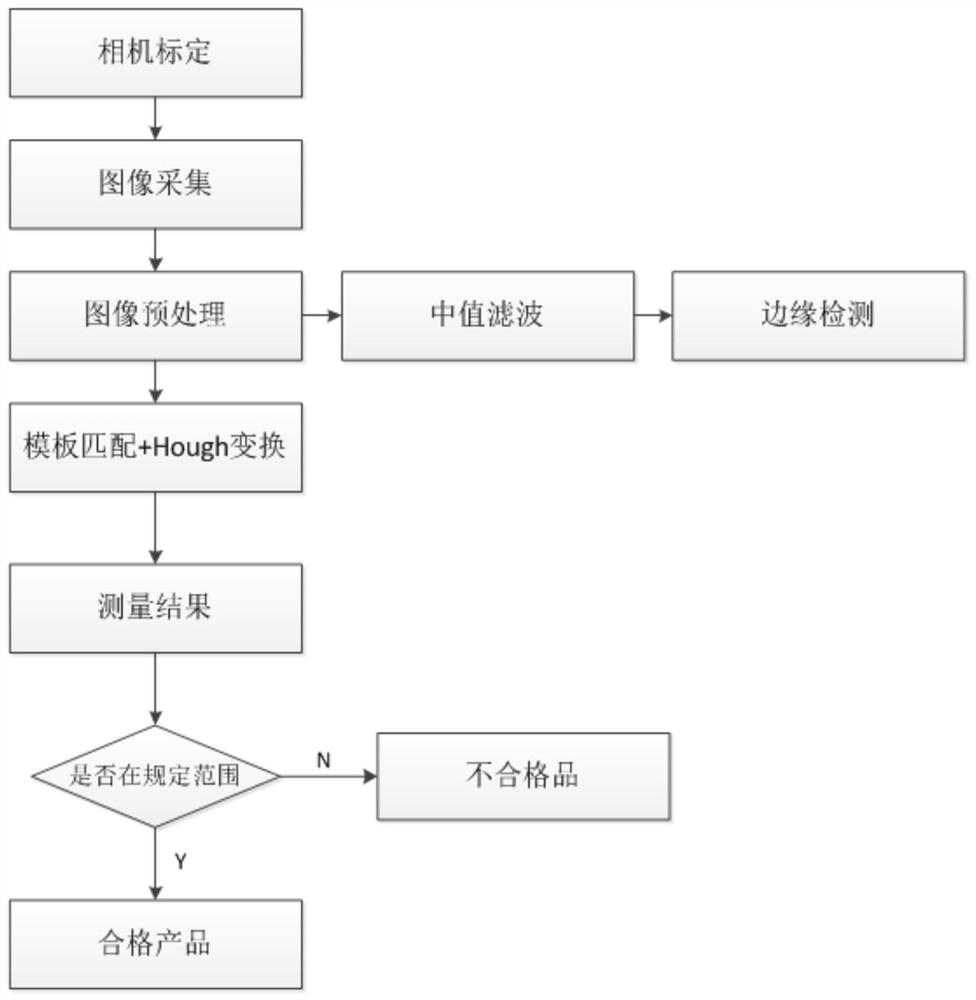

[0028] Such as figure 1 — image 3 As shown, the present invention provides a mobile phone battery size and appearance defect detection system, which is based on machine vision technology, including:

[0029] An optical imaging system, the optical imaging system is used for image acquisition of the mobile phone battery to be detected;

[0030] A light source, which is used to improve image acquisition conditions;

[0031] an image capture system, the image capture system is in communication with the optical imaging system for capturing images collected by the optical imaging system;

[0032] An image acquisition and digitization system, the image acquisition and digitization system communicates with the image capture system, and is used to preprocess the images captured by...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap