Glass transition brittleness factor analysis method based on calorimetric testing

A technology of glass transition and factor analysis, applied in the investigation stage/state change, etc., can solve the problems of difficult measurement and low precision, achieve the effect of simple operation, reduce experimental error, and improve data reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

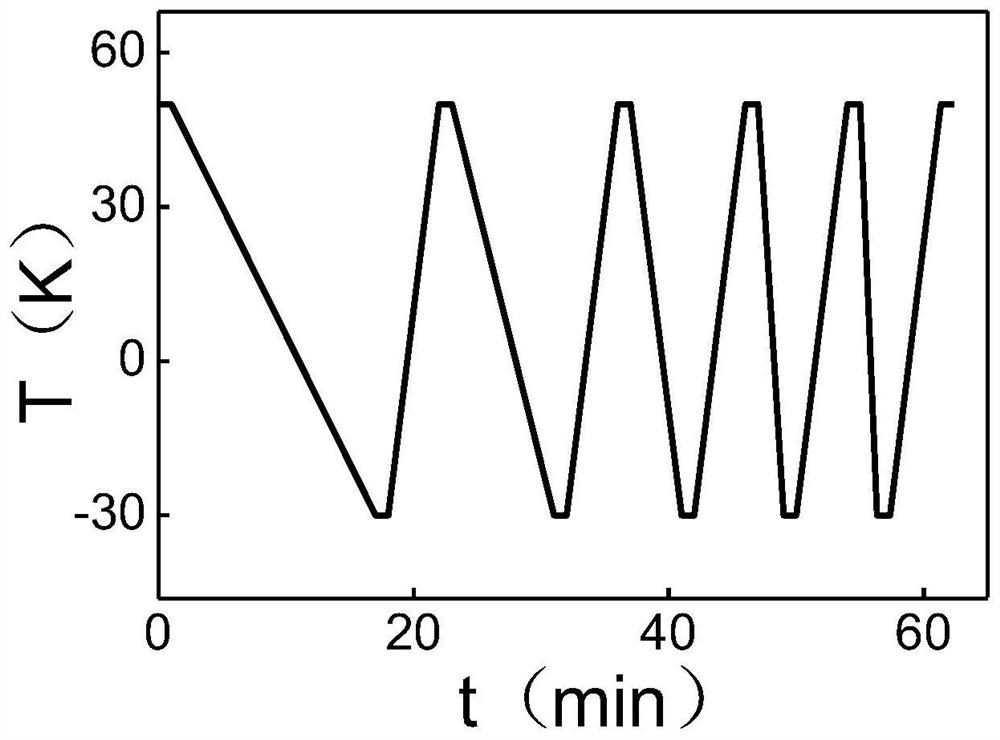

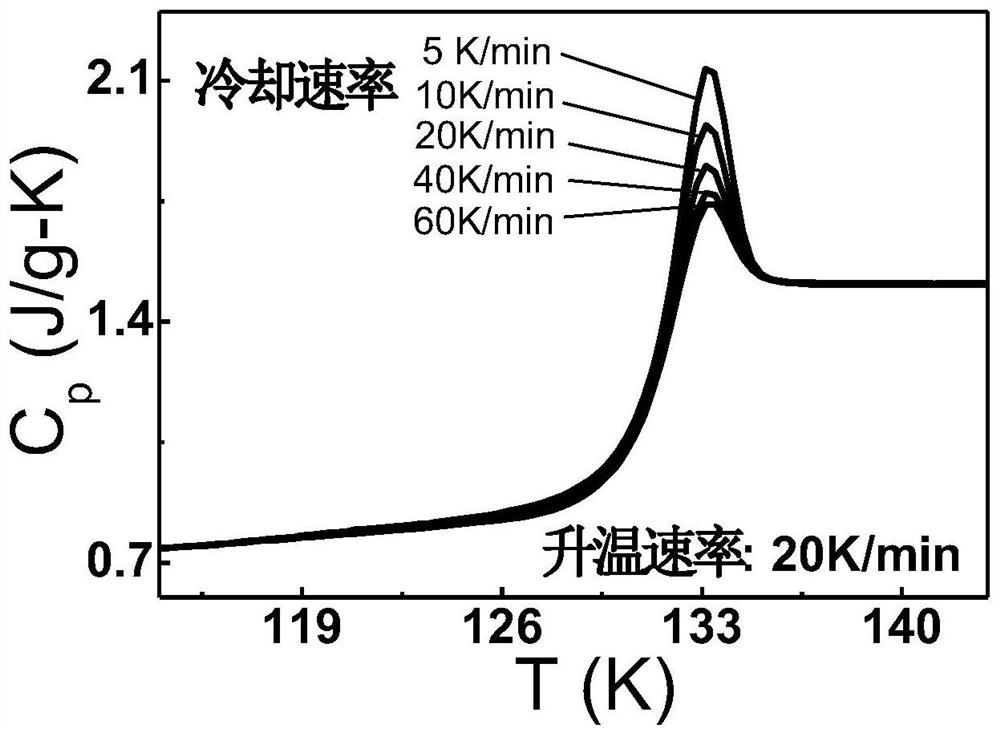

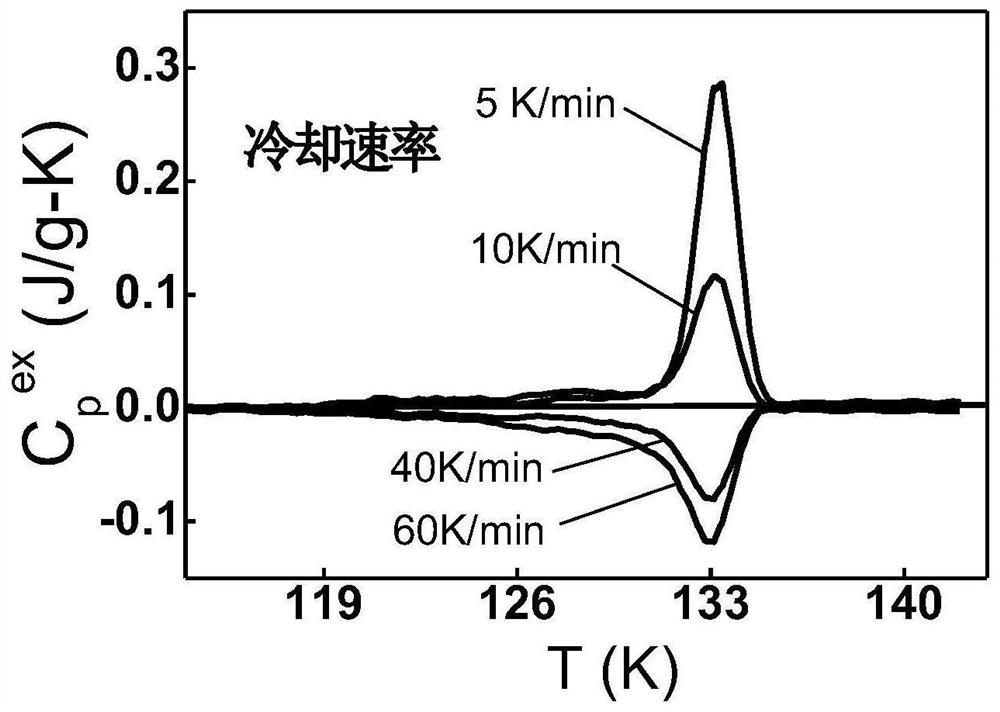

[0040] The invention is a glass transition brittleness factor analysis method based on calorimetry test, which includes calorimetry test of glass forming material and fitting process of glass transition parameters to obtain the glass transition brittleness factor of the material. The method is an indirect experimental test method designed for glassy materials, and a differential calorimetry scanner is used to perform a calorimetric test on the substance, and the same substance is obtained at a cooling rate of 5, 10, 20, 40, and 60K / min respectively. Five different glass states, for five different glass states at the same heating rate of 20K / min to obtain the heating heat flow curves of different glass states. The standard structure temperature of the substance is obtained by fitting and theoretically calculating the temperature rise heat capacity curve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com