Novel nano waterproof board and manufacturing method thereof

A production method and technology of waterproof boards, which are applied in the field of boards, can solve the problems of unfavorable promotion and high cost, and achieve the effects of wide application, low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

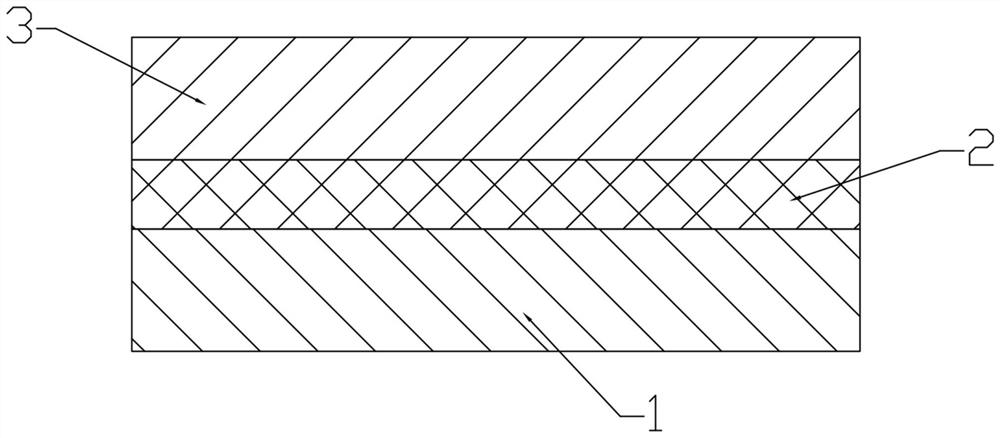

[0022] In conjunction with the accompanying drawings, a new type of nano-waterproof board includes a waterproof board base material 1, and the waterproof board base material 1 is provided with a mixed layer 2 and a nano-layer 3 in sequence;

[0023] The mixed layer 2 is the part where the nano layer 3 penetrates into the base material 1 of the waterproof board.

[0024] The waterproof board substrate 1 is particle board.

[0025] The thickness of the mixed layer 2 is 10mm.

[0026] The nanolayer 3 is structured by siloxane bonds.

[0027] A method for making a novel nano-waterproof board, specifically comprising the following steps:

[0028] 1) Treat the substrate: After cutting the substrate according to the requirements, perform waterproof treatment on the cutting edge;

[0029] 2) Brushing the nano-layer: brushing the nano-material waterproof layer on the substrate, so that the nano-material waterproof layer penetrates into the substrate to form a mixed layer;

[0030] ...

Embodiment 2

[0034] In conjunction with the accompanying drawings, a new type of nano-waterproof board includes a waterproof board base material 1, and the waterproof board base material 1 is provided with a mixed layer 2 and a nano-layer 3 in sequence;

[0035] The mixed layer 2 is the part where the nano layer 3 penetrates into the base material 1 of the waterproof board.

[0036] The waterproof board substrate 1 is a medium density fiberboard.

[0037] The thickness of the mixed layer 2 is 20mm.

[0038] The nanolayer 3 is structured by siloxane bonds.

[0039] A method for making a novel nano-waterproof board, specifically comprising the following steps:

[0040] 1) Treat the substrate: After cutting the substrate according to the requirements, perform waterproof treatment on the cutting edge;

[0041] 2) Brushing the nano-layer: brushing the nano-material waterproof layer on the substrate, so that the nano-material waterproof layer penetrates into the substrate to form a mixed laye...

Embodiment 3

[0046] In conjunction with the accompanying drawings, a new type of nano-waterproof board includes a waterproof board base material 1, and the waterproof board base material 1 is provided with a mixed layer 2 and a nano-layer 3 in sequence;

[0047] The mixed layer 2 is the part where the nano layer 3 penetrates into the base material 1 of the waterproof board.

[0048] The base material 1 of the waterproof board is a plywood.

[0049] The thickness of the mixed layer 2 is 15mm.

[0050] The nanolayer 3 is structured by siloxane bonds.

[0051] A method for making a novel nano-waterproof board, specifically comprising the following steps:

[0052] 1) Treat the substrate: After cutting the substrate according to the requirements, perform waterproof treatment on the cutting edge;

[0053] 2) Brushing the nano-layer: brushing the nano-material waterproof layer on the substrate, so that the nano-material waterproof layer penetrates into the substrate to form a mixed layer;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com