High-purity ammonia tank car heating system

A heating system and high-purity ammonia technology, which is applied to tank trucks, motor vehicles, goods transport vehicles, etc., can solve problems such as increased safety risks and increased energy consumption, and achieve reduced energy consumption, good heating efficiency, and good practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

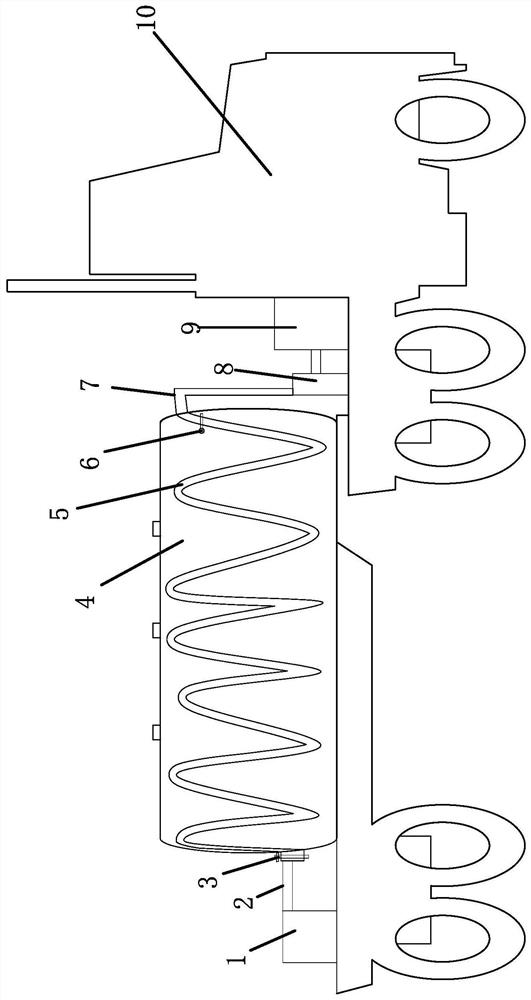

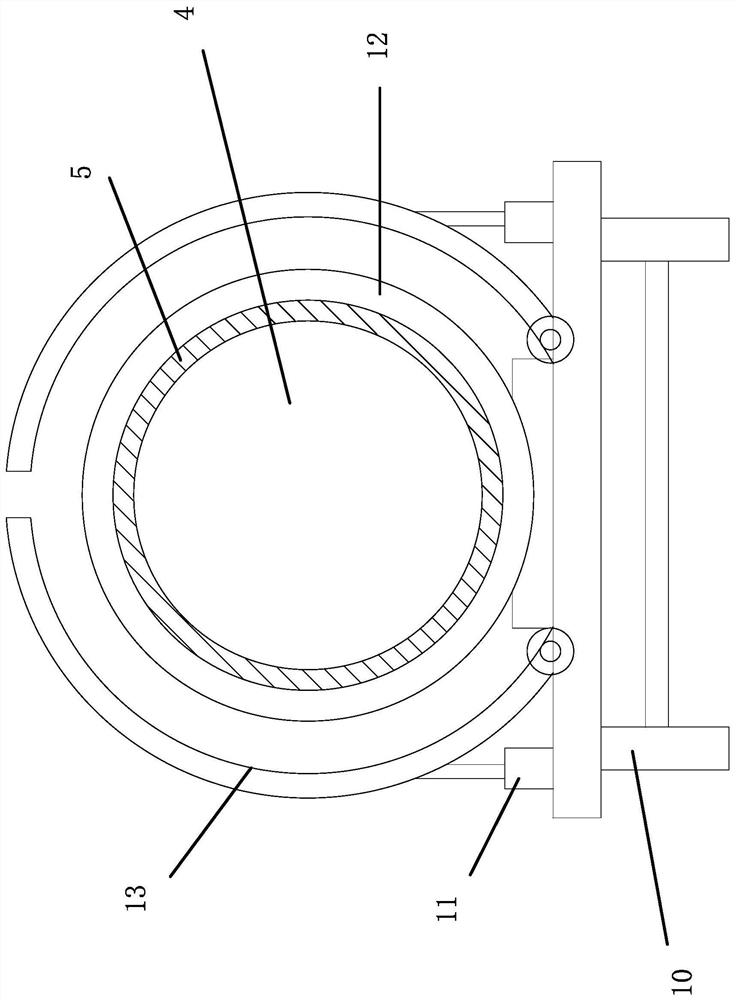

[0017] like Figure 1-2 As shown, a high-purity ammonia tank car heating system includes a tank car 10, an air energy external unit 9, a heat exchange coil 5, a compressor 8, a tank car storage tank 4, an isolation cover and a cylindrical solar heat collector The device 12 is characterized in that the heat exchange coil 5 is wound on the outer surface of the storage tank 4 of the tank car, the air energy external unit 9 and the compressor 8 are fixed on the tank car 10, and the air energy external Machine 9 is connected with compressor 8, and described compressor 8 is connected with heat exchange coil 5, and described solar heat collector 12 is sleeved on the outside of tank car storage tank 4, and described solar heat col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com