Sorting method of connecting rod balance wheel sorting machine

A sorter and connecting rod technology, which is applied in the field of logistics and warehousing, can solve the problems of complex structure of transmission mechanism and swing drive mechanism, large consumption of swing drive force, wrong sorting results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

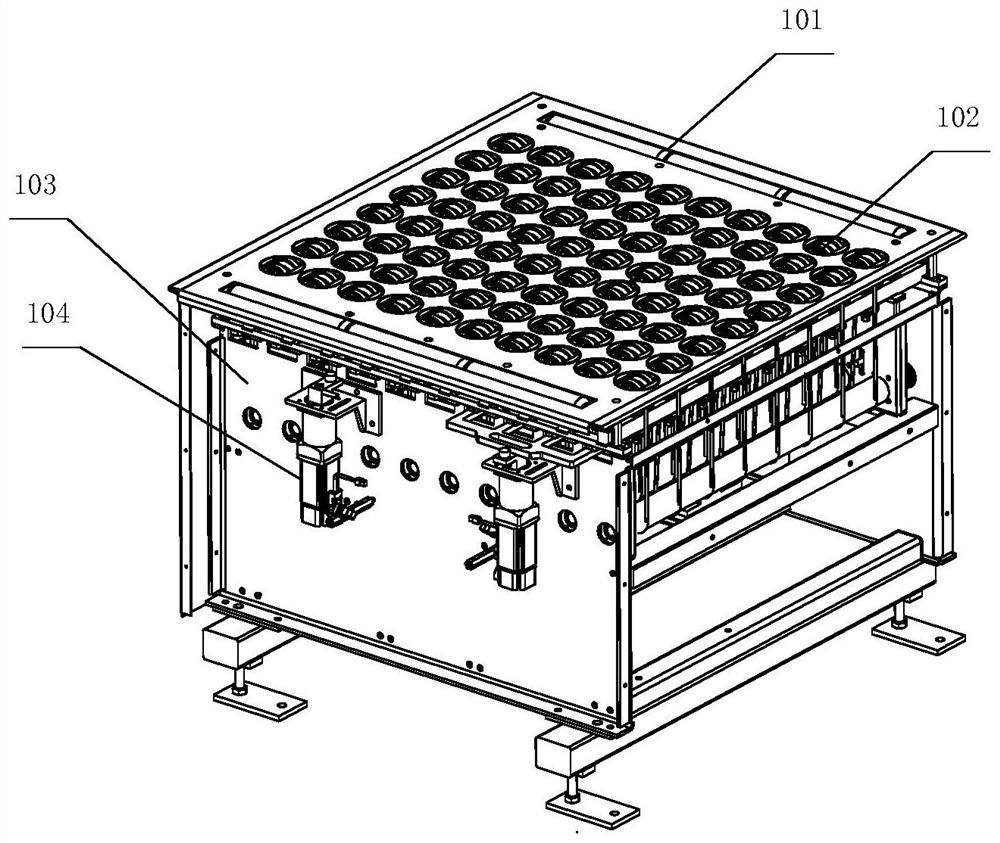

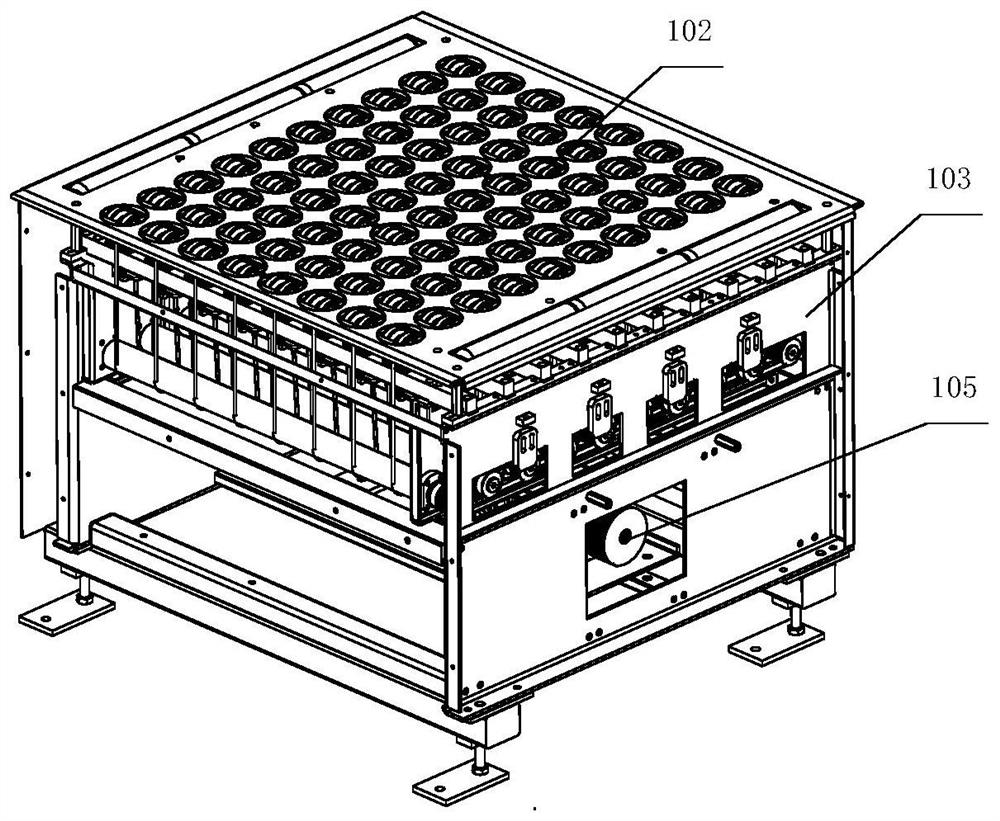

[0033] Embodiment 1, as shown in the above drawings, the sorting method of the link balance wheel sorter described in this application is applied. The link balance wheel sorter includes a shell module 101, a balance wheel module 102, a machine Frame module 103, swing power unit 104 and conveying power unit 105.

[0034] Wherein, the balance wheel module 102, the swing power unit 104 and the transmission power unit 105 are respectively installed on the frame module 103;

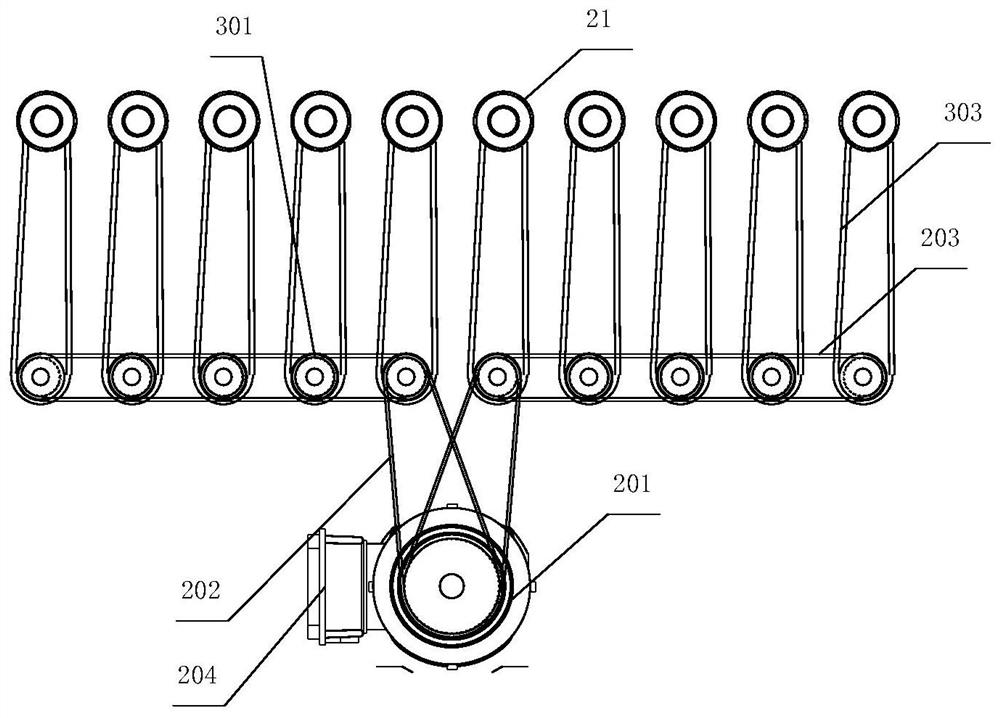

[0035] 80 sets of balance wheel modules are distributed in rows and columns, and the swing power unit 104 includes a set of reversing levers 403 located below the 8 sets of balance wheel modules 102 in each row. Between the reversing levers 403 and each balance wheel module A steering rod 404 is connected between the balance wheel bracket shaft 23 of 102, and the steering rod 404 is a U-shaped connecting rod structure;

[0036] There are 8 groups of balance wheel modules 102 in each row, and the balance wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com