Pressure swing adsorption nitrogen-making device with centralized pollution discharge function

A pressure swing adsorption, functional technology, applied in nitrogen compounds, transportation and packaging, nitrogen purification/separation, etc., can solve the problems of inconvenient centralized discharge of pollutants, affecting the use of nitrogen generators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

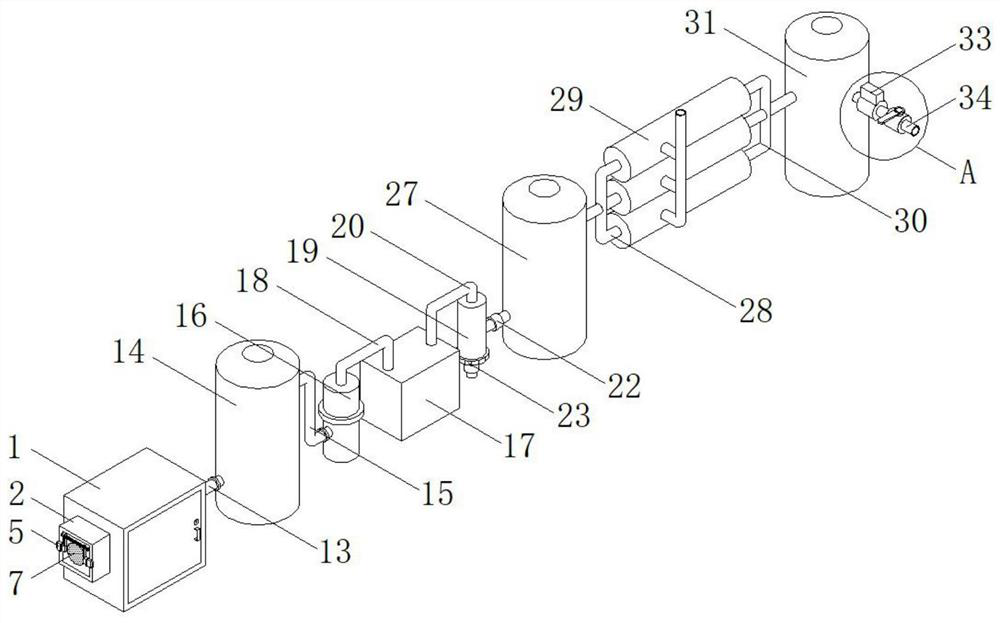

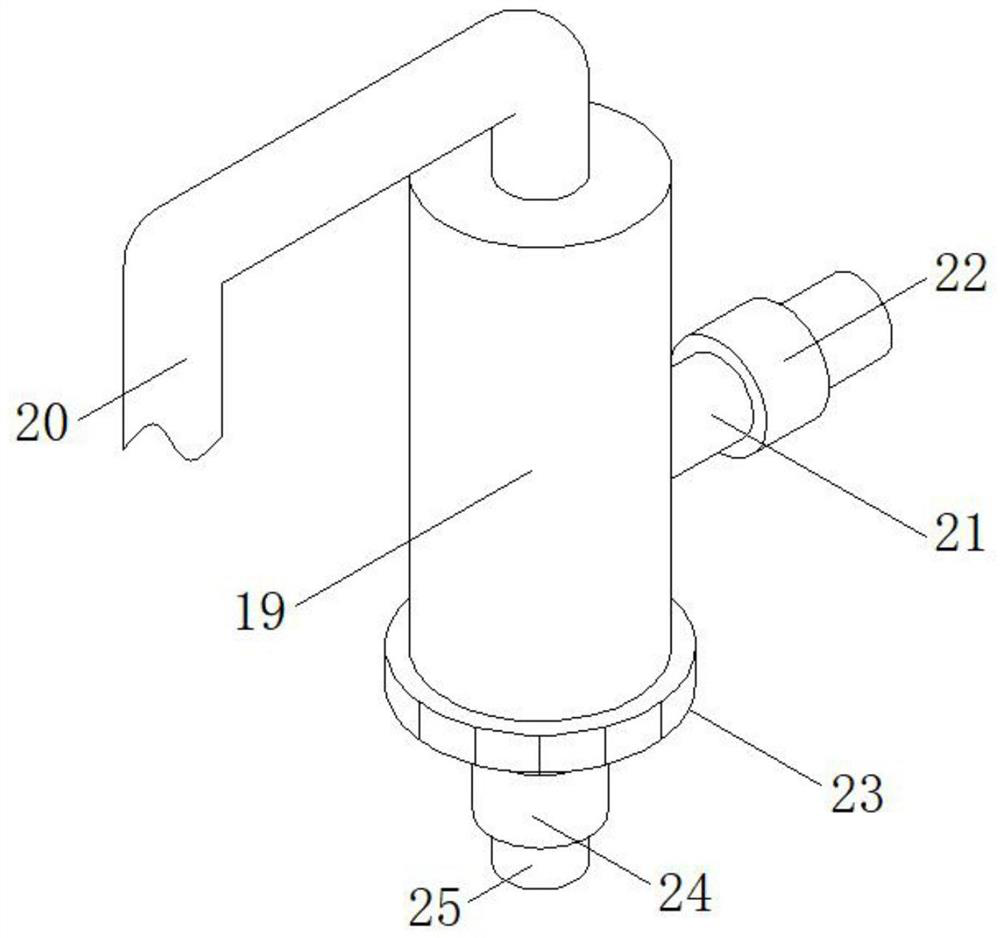

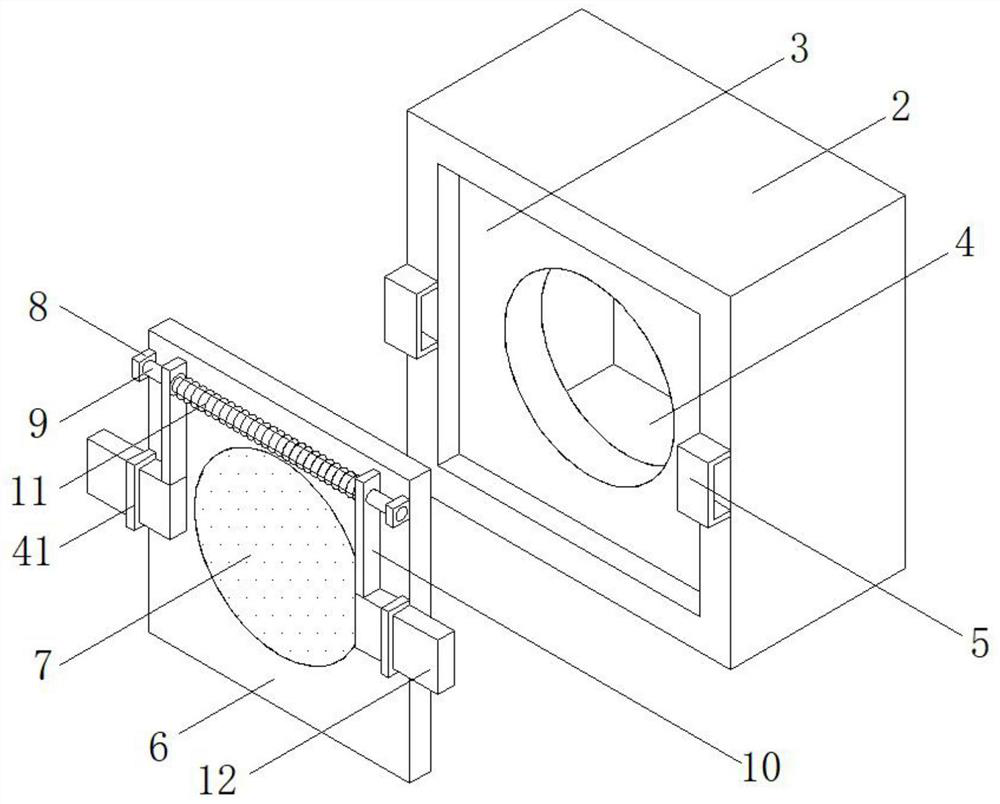

[0027] Example: such as Figure 1-6 As shown, the present invention has a pressure swing adsorption nitrogen generating device with a centralized blowdown function, comprising a protective box 1, the right side of the protective box 1 is provided with a first gas storage mechanism, the first gas storage mechanism consists of a first connecting pipe 13, The first gas storage tank 14 and the second connecting pipe 15 are composed, one end of the first connecting pipe 13 is fixedly communicated with the first gas storage tank 14, and the other end of the first connecting pipe 13 extends to the inside of the protective box 1 and is fixedly communicated with Air compressor, the left side of protective box 1 is provided with intake mechanism, and intake mechanism is made up of intake pipe 2, partition plate 3, air intake hole 4 and first limiting frame 5, and the quantity of first limiting frame 5 There are two, the left side of the intake pipe 2 is provided with a filter mechanism,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com