Salicylic acid production wastewater treatment method

A technology for producing wastewater and treatment methods, applied in water/sewage treatment, water/sludge/sewage treatment, mechanically oscillating water/sewage treatment, etc. Simple operation, efficient removal, easy industrial application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

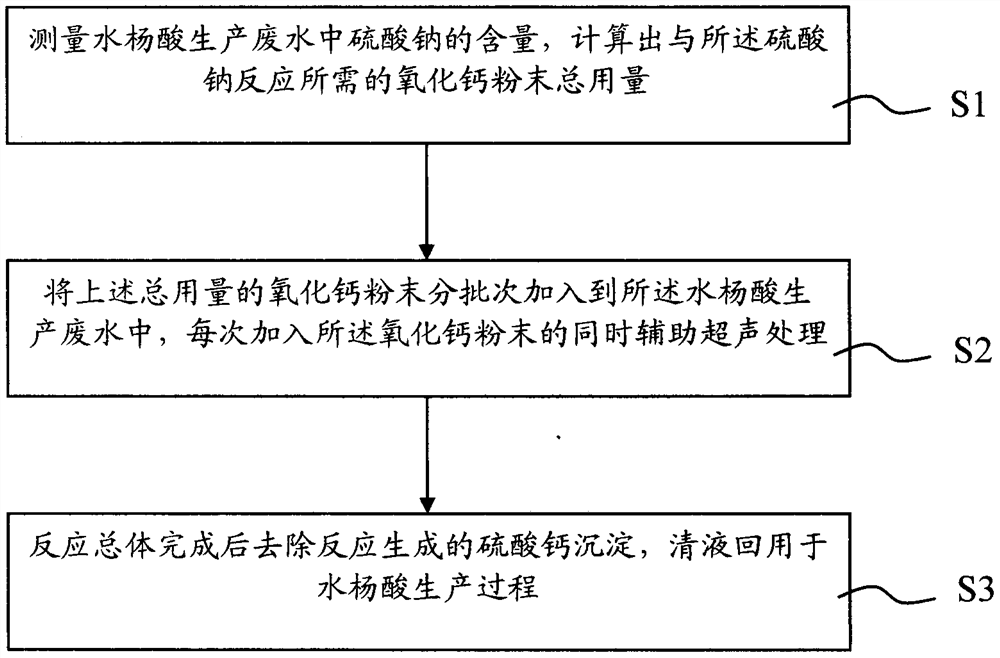

Method used

Image

Examples

Embodiment 1

[0030] Measure the content of sodium sulfate in the salicylic acid production wastewater, and calculate the total consumption of calcium oxide powder required to react with the sodium sulfate. At room temperature, divide the calcium oxide powder required for the reaction into 3 batches, start timing when the first batch of calcium oxide powder is added to the salicylic acid production wastewater, add the second batch of calcium oxide powder after 10 minutes of reaction, After continuing the reaction for 10 minutes, add the third batch of calcium oxide powder, and continue the reaction for 10 minutes until the reaction ends. During the reaction process, the whole process was stirred, and the stirring speed was 150 rpm. Ultrasonic treatment was performed each time calcium oxide powder was added, each ultrasonic time was 2.5min, ultrasonic power was 50W / L, and ultrasonic frequency was 90kHz. Use external ultrasonic vibrator or interpolation probe ultrasonic. After the reaction ...

Embodiment 2

[0032] Measure the content of sodium sulfate in the salicylic acid production wastewater, and calculate the total consumption of calcium oxide powder required to react with the sodium sulfate. At room temperature, divide the calcium oxide powder required for the reaction into 3 batches, start timing when the first batch of calcium oxide powder is added to the salicylic acid production wastewater, add the second batch of calcium oxide powder after 10 minutes of reaction, After continuing the reaction for 10 minutes, add the third batch of calcium oxide powder, and continue the reaction for 10 minutes until the reaction ends. During the reaction process, the whole process was stirred, and the stirring speed was 170 rpm. Ultrasonic treatment was performed each time the calcium oxide powder was added, the ultrasonic time was 2 min each time, the ultrasonic power was 60 W / L, and the ultrasonic frequency was 80 kHz. Use external ultrasonic vibrator or interpolation probe ultrasonic...

Embodiment 3

[0034] Measure the content of sodium sulfate in the salicylic acid production wastewater, and calculate the total consumption of calcium oxide powder required to react with the sodium sulfate. At room temperature, divide the calcium oxide powder required for the reaction into 4 batches, start timing when the first batch of calcium oxide powder is added to the salicylic acid production wastewater, and add the second batch of calcium oxide powder after 7.5 minutes of reaction After another 7.5 minutes of reaction, the third batch of calcium oxide powder was added, and after the reaction was continued for 7.5 minutes, the fourth batch of calcium oxide powder was added until the reaction ended. During the reaction process, the whole process was stirred, and the stirring speed was 180 rpm. Ultrasonic treatment was performed each time the calcium oxide powder was added, and the ultrasonic time was 1.5 min each time, the ultrasonic power was 70W / L, and the ultrasonic frequency was 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com