Integrated sludge water treatment system

A treatment system and sludge discharge technology, applied in water/sludge/sewage treatment, sludge treatment, water/sewage multi-stage treatment, etc., can solve problems such as high cost, easy damage of equipment, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

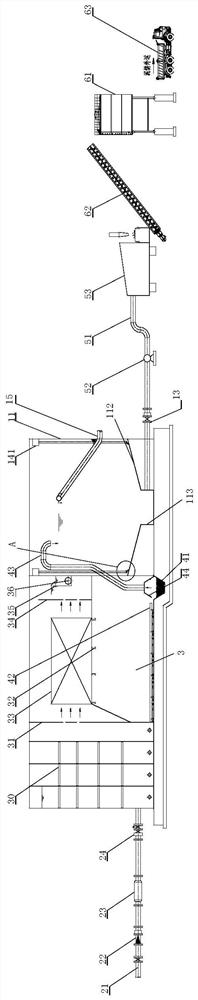

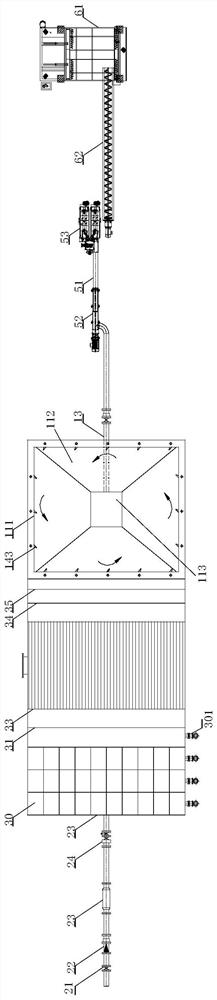

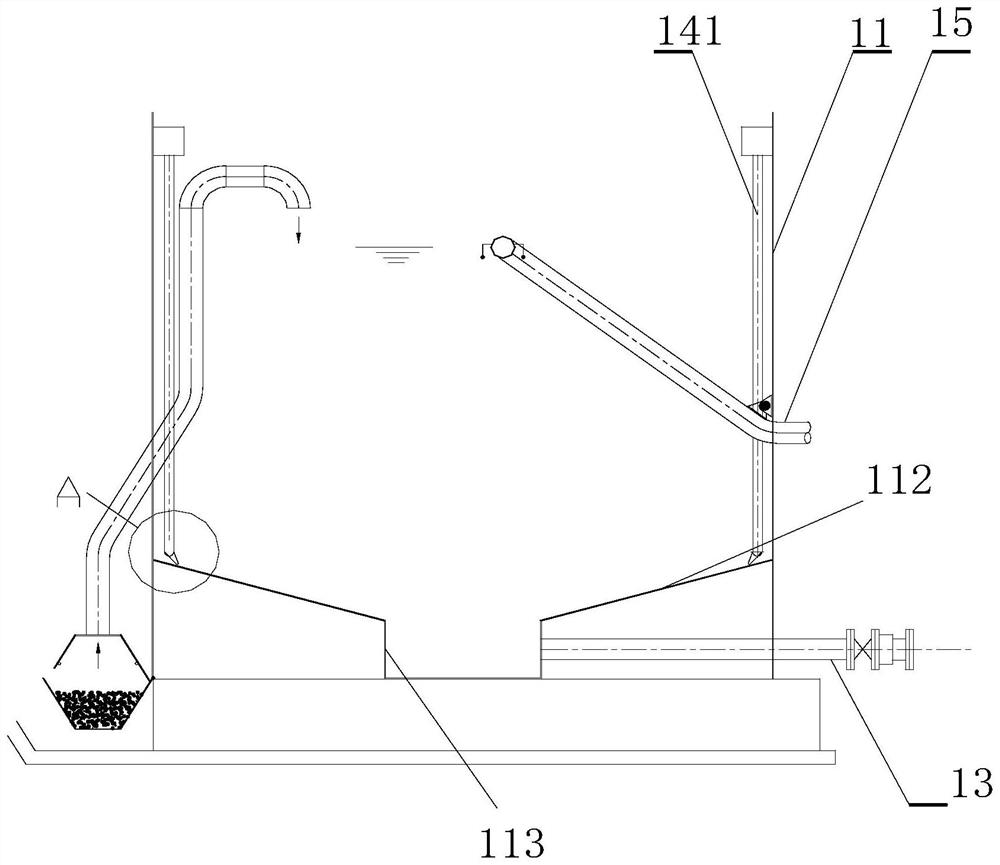

[0030] Such as Figure 1-5 As shown, an integrated sludge treatment system includes a mixing device, a flocculation tank 30, a sedimentation device, a thickening device, a sludge lifting device, a dehydration device and a delivery device. The mixing device includes a mixing pipe 21, an electromagnetic flowmeter 22, Pipeline mixer 23 and water inlet valve 24, described mixing pipe 21 one end is communicated with flocculation pond; Described electromagnetic flowmeter 22 selects conventional electromagnetic flowmeter for use, and it is located on the mixing pipe, is used for detecting the flow of muddy water in the mixing pipe ; The pipeline mixer 23 selects a micro-resistance pipeline mixer, and its two ends are respectively connected to the mixing tube for adding flocculant in the mixing tube; the water inlet valve 24 is located at the tail end of the mixing tube for controlling the mixing Tube switch.

[0031] Specifically, the flocculation tank 30 is provided with a mud disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com