Concrete curing agent and preparation method thereof

A technology of concrete curing agent and leveling agent, which is applied in the field of concrete additives and can solve the problems of low effective water retention rate of concrete curing agent, inconspicuous concrete curing effect, and inability to repair micro-cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

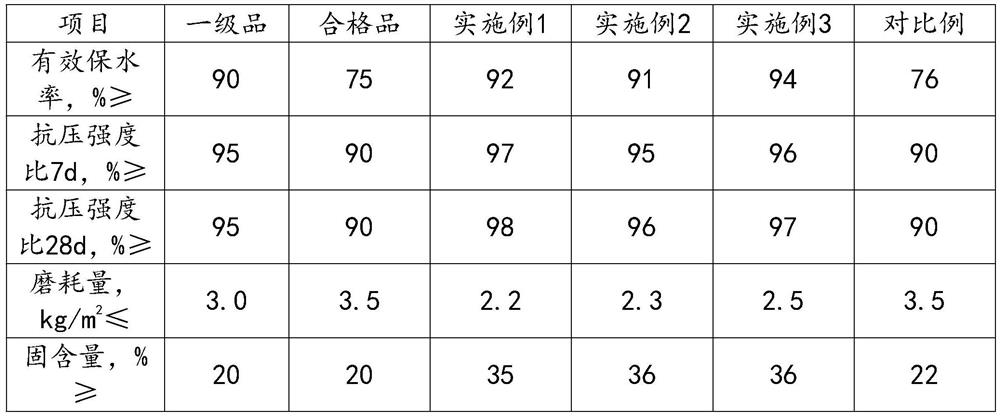

Examples

Embodiment 1

[0033] A concrete curing agent, comprising the following raw materials in parts by weight: 10 parts of paraffin wax emulsion, 10 parts of styrene-acrylic emulsion, 5 parts of repairing microcapsules, 5 parts of sodium silicate, 5 parts of magnesium sulfate, 5 parts of aluminum sulfate, and 4 parts of animal and plant fibers , 10 parts of methyl methacrylate, 1 part of defoamer, 1 part of leveling agent, 0.2 parts of plasticizer and 20 parts of deionized water;

[0034] The concrete curing agent is made by the following steps:

[0035] The first step, add defoamer, leveling agent and plasticizer into the reactor, stir and mix evenly to obtain organic additives; add sodium silicate, magnesium sulfate, aluminum sulfate and deionized water into the reactor, stir Mix evenly to obtain inorganic additives;

[0036] The second step is to add paraffin wax emulsion, styrene-acrylic emulsion and methyl methacrylate into the reaction kettle in sequence, and stir for 30 minutes under the ...

Embodiment 2

[0048] A concrete curing agent, comprising the following raw materials in parts by weight: 12 parts of paraffin wax emulsion, 15 parts of styrene-acrylic emulsion, 8 parts of repairing microcapsules, 7 parts of sodium silicate, 7 parts of magnesium sulfate, 7 parts of aluminum sulfate, and 8 parts of animal and plant fibers , 15 parts of methyl methacrylate, 1.2 parts of defoamer, 2 parts of leveling agent, 0.3 parts of plasticizer and 25 parts of deionized water;

[0049] The concrete curing agent is made by the following steps:

[0050] The first step, add defoamer, leveling agent and plasticizer into the reactor, stir and mix evenly to obtain organic additives; add sodium silicate, magnesium sulfate, aluminum sulfate and deionized water into the reactor, stir Mix evenly to obtain inorganic additives;

[0051] In the second step, add paraffin emulsion, styrene-acrylic emulsion and methyl methacrylate into the reaction kettle in sequence, stir for 30 minutes under the condit...

Embodiment 3

[0063] A concrete curing agent, comprising the following raw materials in parts by weight: 15 parts of paraffin emulsion, 20 parts of styrene-acrylic emulsion, 10 parts of repairing microcapsules, 8 parts of sodium silicate, 8 parts of magnesium sulfate, 8 parts of aluminum sulfate, and 10 parts of animal and plant fiber , 20 parts of methyl methacrylate, 1.5 parts of defoamer, 3 parts of leveling agent, 0.4 parts of plasticizer and 30 parts of deionized water;

[0064] The concrete curing agent is made by the following steps:

[0065] The first step, add defoamer, leveling agent and plasticizer into the reactor, stir and mix evenly to obtain organic additives; add sodium silicate, magnesium sulfate, aluminum sulfate and deionized water into the reactor, stir Mix evenly to obtain inorganic additives;

[0066] In the second step, add paraffin wax emulsion, styrene-acrylic emulsion and methyl methacrylate into the reactor in sequence, stir for 30 minutes under the condition of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com