Magnetism gathering type eddy current sensor

An eddy current sensor and magnetic gathering technology, which is applied in the direction of material magnetic variables, etc., can solve the problems of low signal strength and detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the following examples are only descriptive and not restrictive, and cannot be used to limit the protection scope of the present invention.

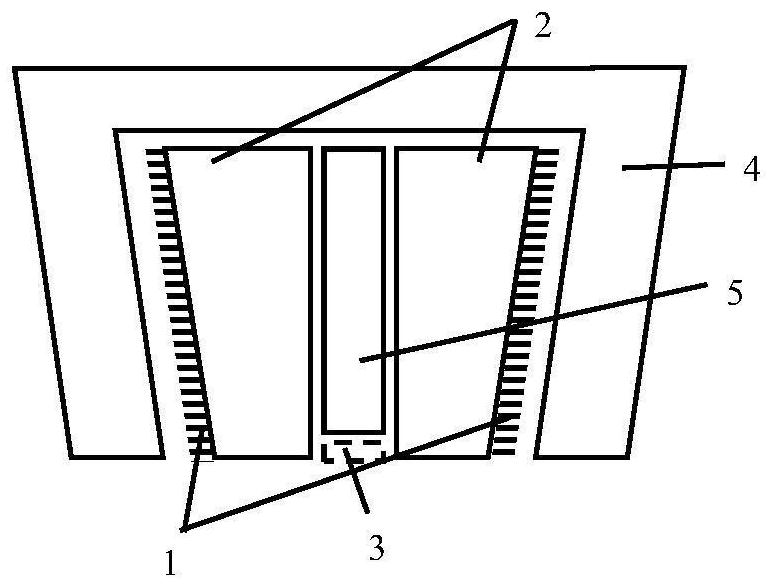

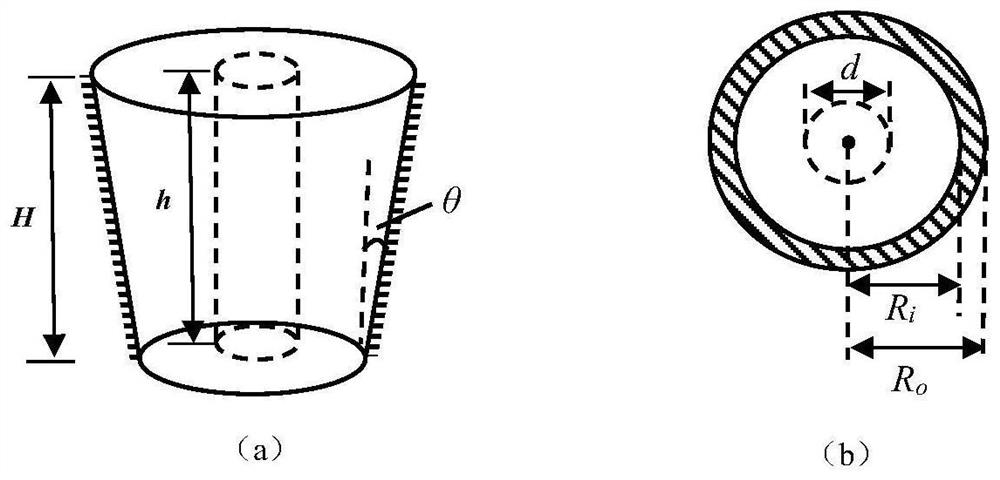

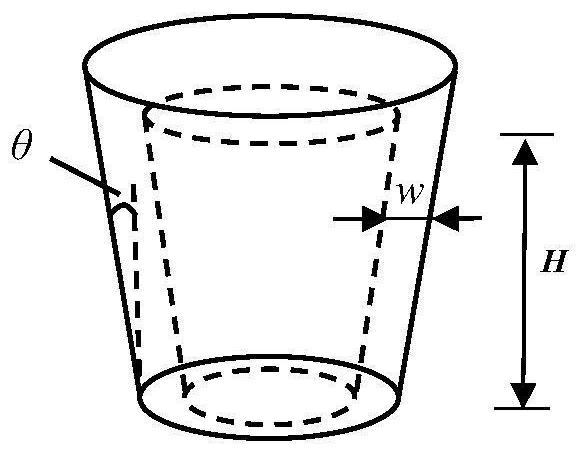

[0026] The schematic diagram of the structure of the magnetic-condensation eddy current sensor is as follows: figure 1 shown. The sensor includes an excitation coil 1 , a coil bobbin 2 , a Hall sensor 3 , a funnel-shaped magnetic shield 4 and a cylindrical ferrite core 5 . The detection object is No. 45 steel sprayed with iron-based amorphous coating, and the specification is 100×50×10 (unit: mm). The excitation coil is funnel-shaped, and the bottom inner diameter, outer diameter, height and wire diameter of the coil play a decisive role in the induced eddy current density and the secondary magnetic field strength in the test piece. The specific size is determined according to the simulation results. According to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com