Nanometer gas sensor modeling method based on equivalent circuit

A gas sensor and equivalent circuit technology, applied in the fields of instruments, electrical digital data processing, computing, etc., can solve the problems of inability to obtain, cumbersome process, time-consuming and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

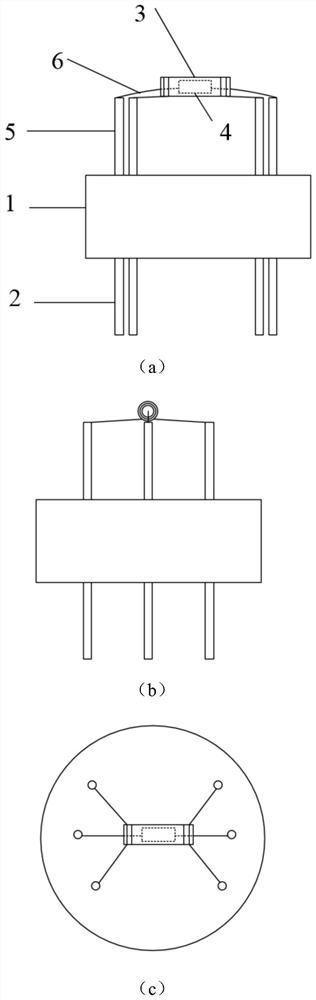

[0031] This example is for figure 1 The shown nanoscale gas sensor for model simulation. In the nano gas sensor, the gas sensitive material is diluted and evenly coated on the surface of the ceramic tube, and the resistance wire is placed inside the ceramic tube, and finally the two ends of the resistance wire and the four pins of the ceramic tube are welded to the base. By changing the voltage at both ends of the resistance wire, the power of the resistance wire is changed so that the temperature changes, and the change of the output current reflects the responsiveness of the material to the gas.

[0032] The response performance of nano gas sensors is affected by many ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com