Modifier for polyolefin resin

A technology for polyolefin resins and modifiers, which is applied in the field of modifiers for polyolefin resins and laminated films, and can solve problems such as adverse effects on heat sealability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

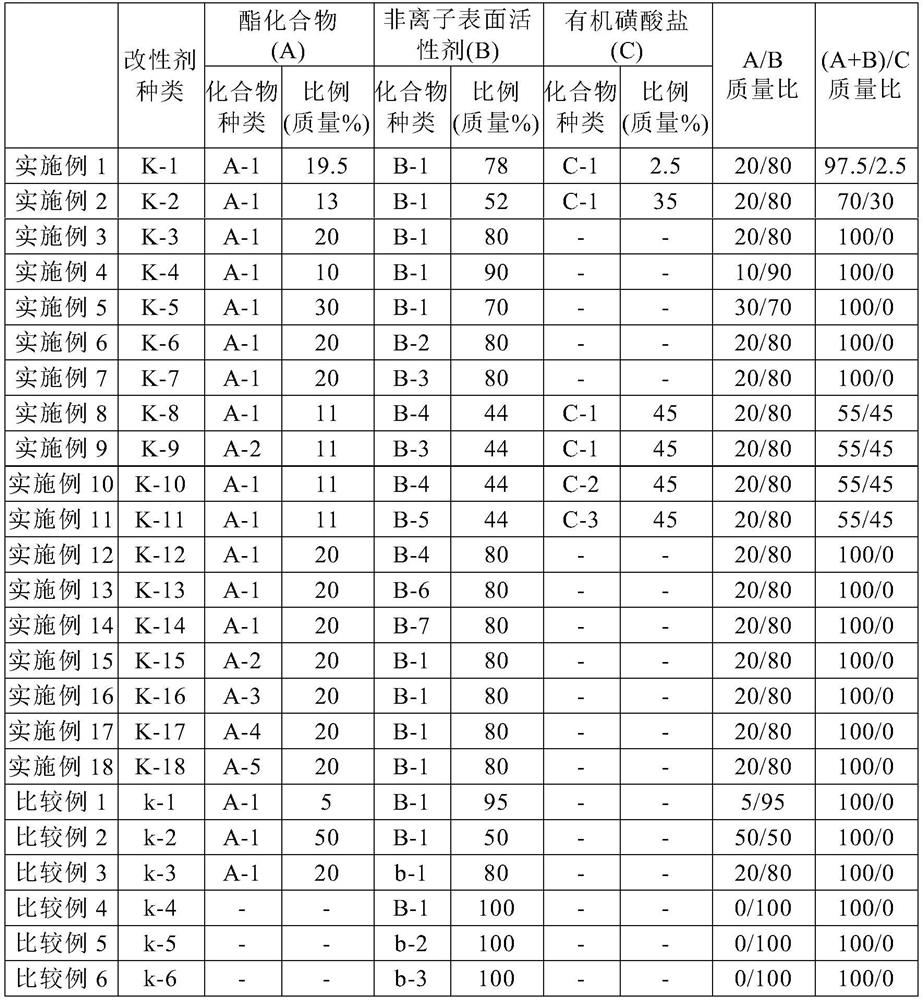

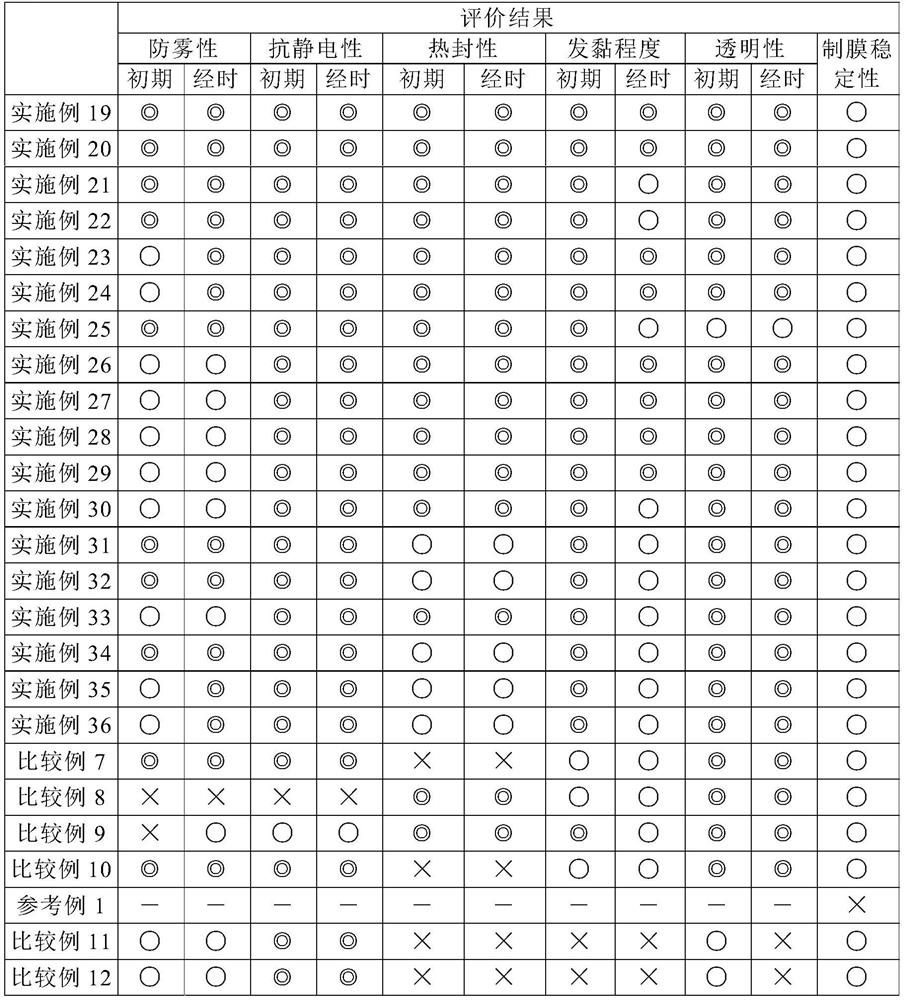

Examples

no. 1 Embodiment approach

[0050] First, a description will be given of a first embodiment of a modifier for a polyolefin resin (hereinafter referred to as a modifier) for concretely realizing the present invention.

[0051] Examples of the ester compound used in the modifier of the present embodiment include those selected from the group of partial esters of dihydric alcohols having 2 to 4 carbon atoms and aliphatic monocarboxylic acids having 8 to 22 carbon atoms. at least one. These may be used alone or in combination of two or more.

[0052] Among the partial esters of dihydric alcohols with 2 to 4 carbon atoms and aliphatic monocarboxylic acids with 8 to 22 carbon atoms, specific examples of dihydric alcohols with 2 to 4 carbon atoms include ethylene glycol, Alcohol, Propylene Glycol, Butylene Glycol, etc. In addition, specific examples of aliphatic monocarboxylic acids having 8 to 22 carbon atoms include caprylic acid, nonanoic acid, capric acid, undecylic acid, undecylenic acid, lauric acid, ...

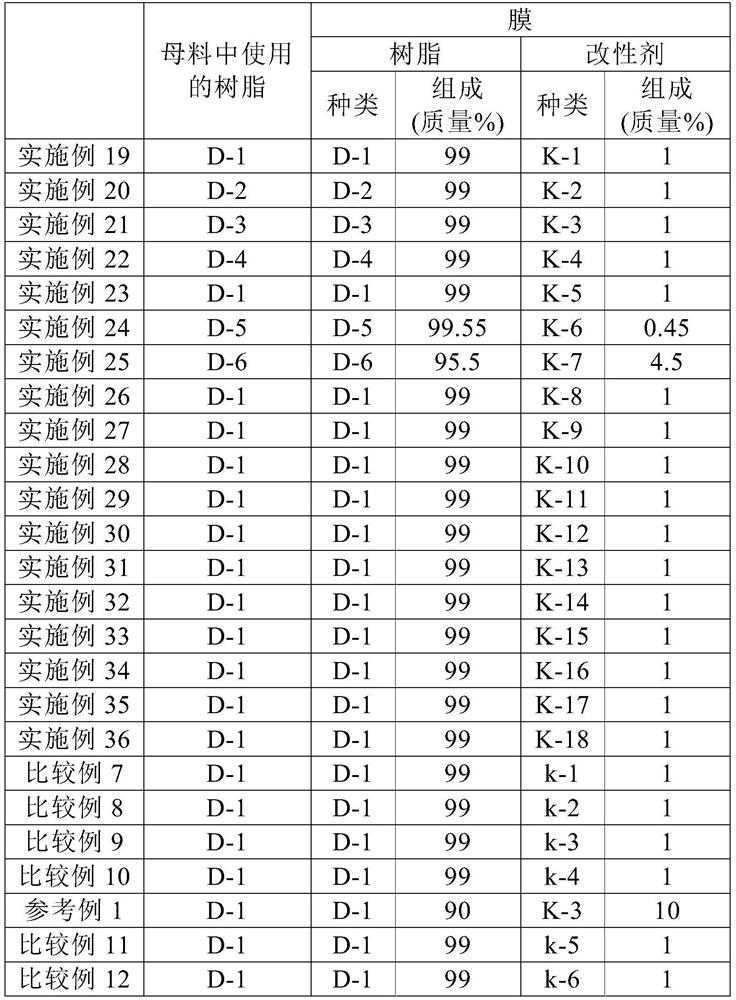

no. 2 Embodiment approach

[0082]Next, a second embodiment of the polyolefin-based resin composition (hereinafter referred to as the resin composition) for realizing the present invention will be described. The resin composition of the present embodiment contains the modifier of the first embodiment described above in a polyolefin resin. The resin composition of this embodiment contains the modifier of 1st Embodiment in the ratio of 0.45-5.0 mass % in a resin composition. When the total content ratio of the polyolefin resin and the modifier of the first embodiment is 100 parts by mass (100 mass %), it is preferable to contain the polyolefin resin in a ratio of 99.55 to 95.0 parts by mass (mass %), and to The modifying agent of the first embodiment is contained in a ratio of 0.45 to 5.0 parts by mass (mass %). By limiting to this range, especially antifogging property and antistatic property can be further improved. In addition, film forming stability when the resin composition is molded into a film ca...

no. 3 Embodiment approach

[0087] Next, 3rd Embodiment which concretely demonstrates the modified polyolefin resin film (henceforth a film) of this invention is demonstrated. The film of the present embodiment is obtained by molding using the resin composition of the second embodiment. The film of the present embodiment contains the modifying agent of the first embodiment in a ratio of 0.45 to 5.0% by mass in the film. By limiting to this range, especially antifogging property and antistatic property can be further improved. In addition, film formation stability can be improved.

[0088] A known method can be used for the molding method of the film of this embodiment, and examples of the molding method include inflation molding such as air-cooled inflation molding, air-cooled two-stage inflation molding, and water-cooled inflation molding, and use as a T-die. T-die molding of straight manifold type, coat hanger type, and a combination of them. The film of the present embodiment can be formed by any o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com