Filter material polarization module for air filtering device and air filtering device

An air filter device and filter material technology, applied in the field of indoor air purification, can solve the problems of low long-term use efficiency, easy generation of ozone, weak polarization electric field, etc., to avoid coking of the filter material, increase filtration capacity, and strong polarization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

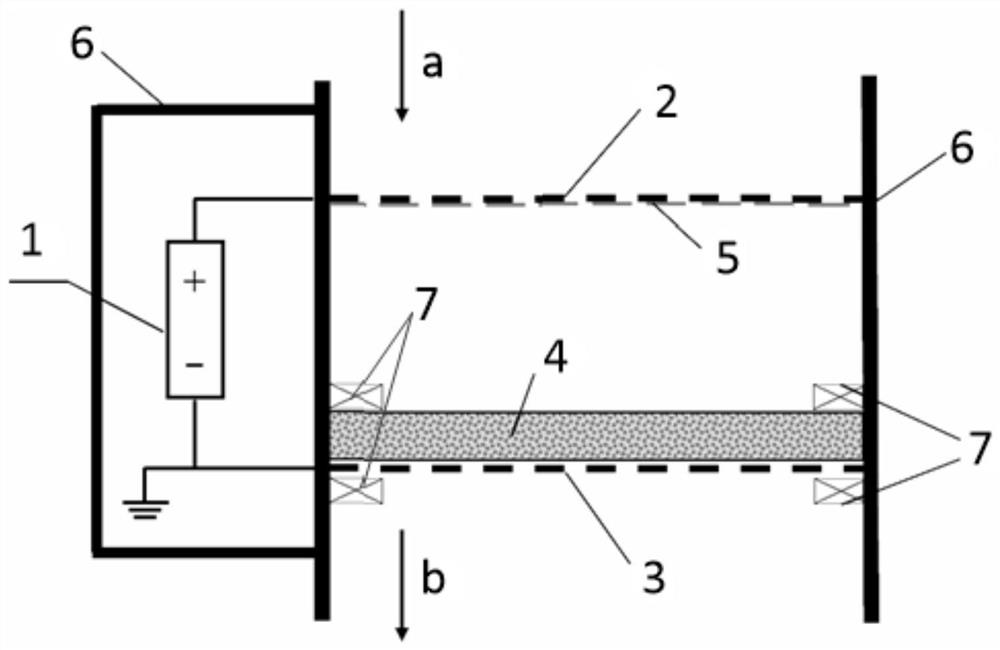

[0036] Exemplary embodiments of the present application are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present application, but are not intended to exhaust all possible ways of the present application, nor are they used to limit the scope of the present application.

[0037] For the convenience of description, a and b are introduced in this application to indicate the gas flow direction, and the gas flows from a to b, and a and b do not represent specific positions.

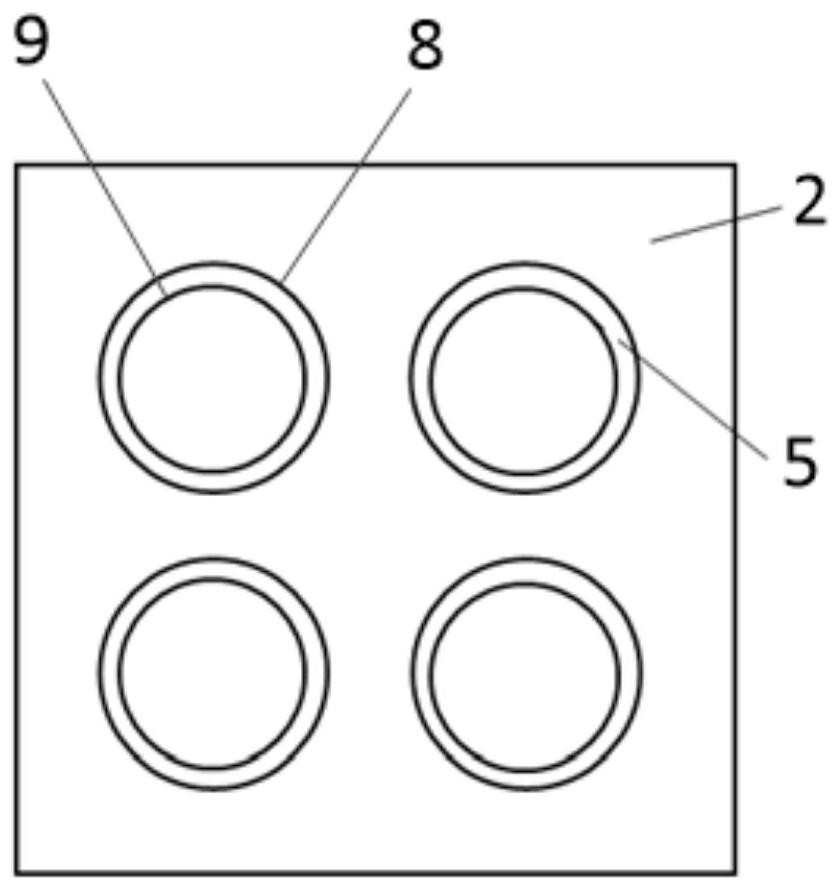

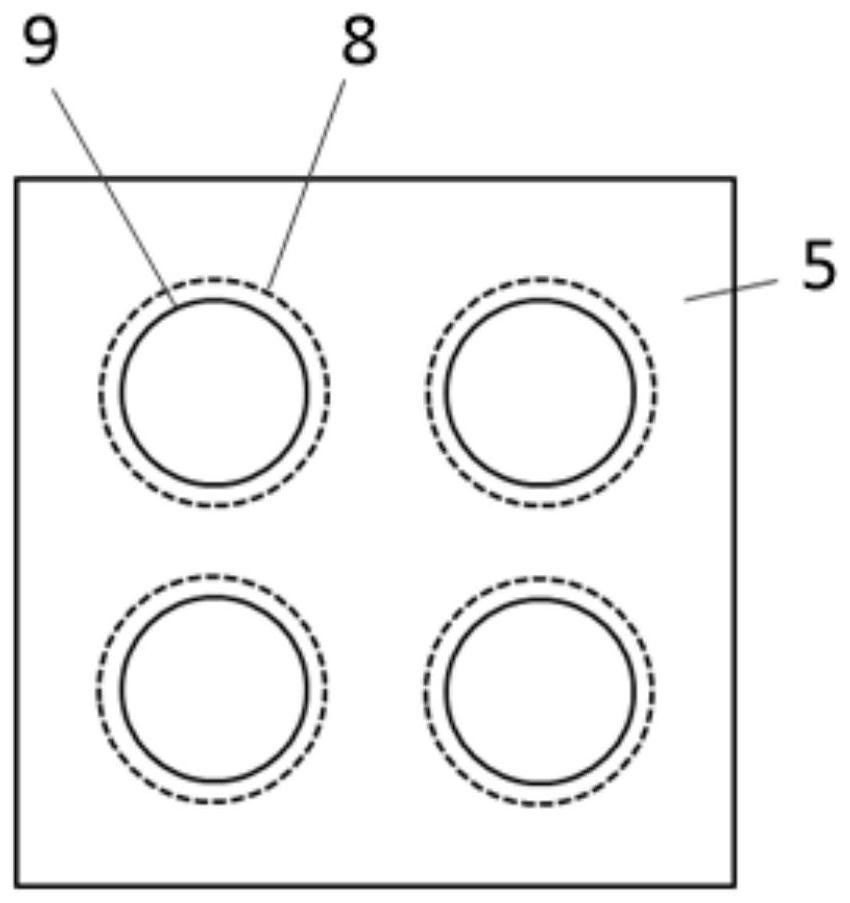

[0038] This application is based on particle charging-filter material polarization filtration technology, the particle charging module (not shown) charges the particles in the upstream gas, and the filter material polarization module makes the downstream filter screen 4 (described later) be polarized Electrochemical induction, resulting in the separation of positive and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com