Foamed nickel substrate in-situ loaded titanium dioxide nanowire array material as well as preparation method and application thereof

A nanowire array, titanium dioxide technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. Reaction sites and other issues, to achieve the effect of mild conditions, close connection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

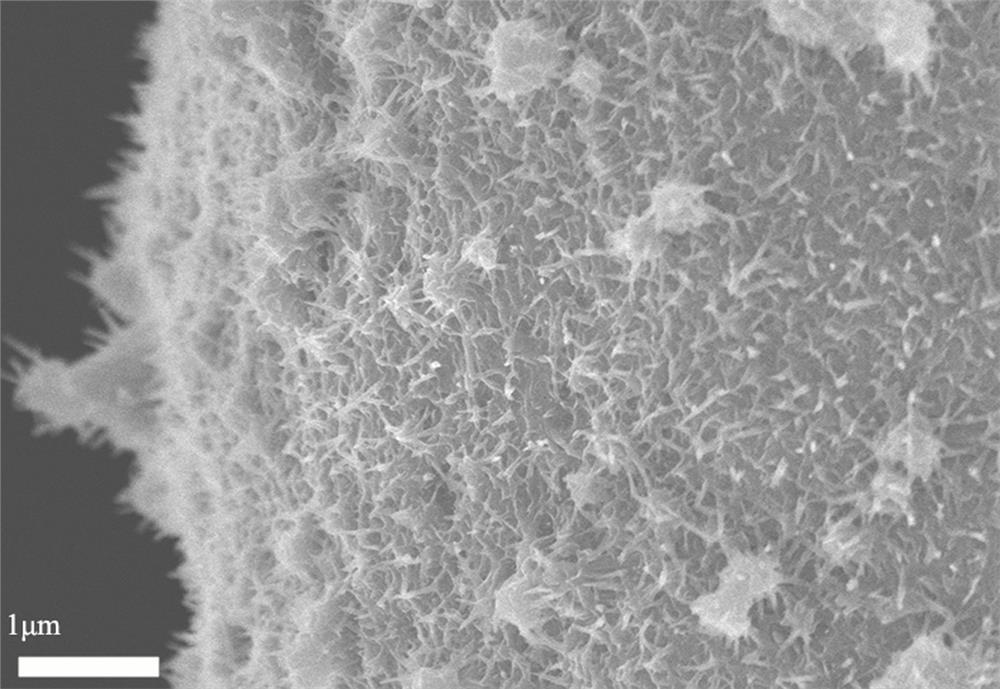

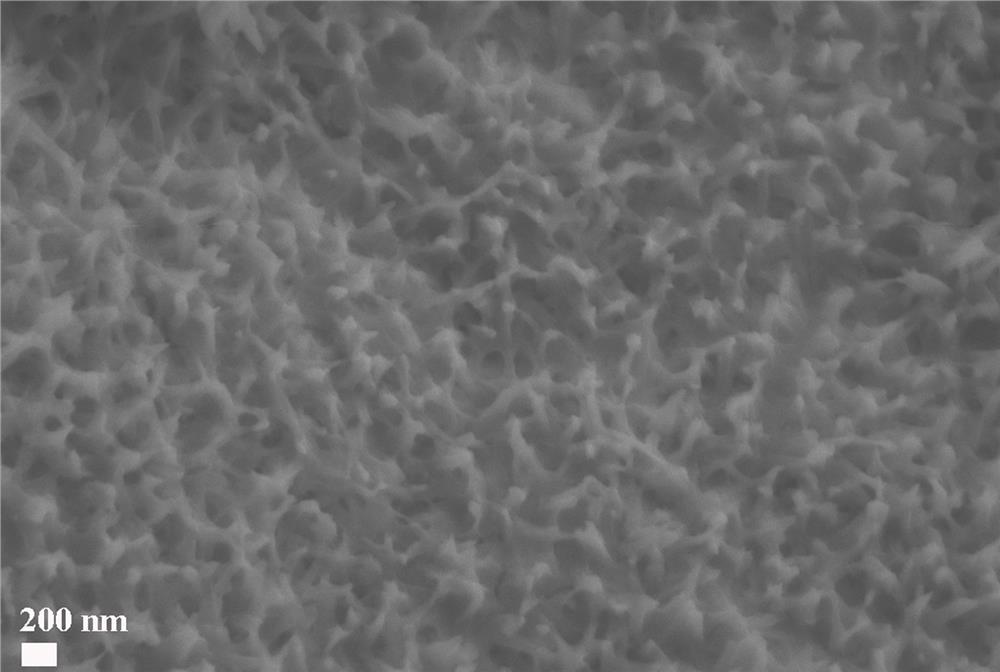

[0031] A method for preparing a nickel foam substrate in-situ loaded titanium dioxide nanowire array material, the steps are as follows:

[0032] (1) The nickel foam with a width of 1 cm and a length of 4 cm was sequentially immersed in 15 mL of 1 mol / L hydrochloric acid, deionized water, acetone and absolute ethanol, ultrasonically cleaned at 30 °C for 5 min, and placed in Dry in an oven at 60°C until completely dry.

[0033] (2) Stir in 3 mL of glycerol, 0.5 mL of tetrabutyl titanate and 27 mL of absolute ethanol at room temperature until a uniform mixture is formed. Then transfer it to a 50 mL polytetrafluoroethylene reactor, add the pretreated dry nickel foam, and conduct a hydrothermal reaction at 180 °C for 12 h.

[0034] (3) The hydrothermal product was taken out, washed with ethanol three times, and dried at 60°C for 30 min to obtain the material precursor 1 of titanium dioxide nanowire array supported in situ on a nickel foam substrate.

[0035] (4) Put the precurso...

Embodiment 2

[0037] A method for preparing a nickel foam substrate in-situ loaded titanium dioxide nanowire array material, the steps are as follows:

[0038] (1) The nickel foam with a width of 1 cm and a length of 4 cm was sequentially immersed in 15 mL of 1 mol / L hydrochloric acid, deionized water, acetone and absolute ethanol, ultrasonically cleaned at 30 °C for 5 min, and placed in Dry in an oven at 60°C until completely dry.

[0039] (2) Add 5 mL of glycerol and 0.5 mL of tetrabutyl titanate to 25 mL of absolute ethanol, and stir at room temperature until a uniform mixture is formed. Then transfer it to a 50 mL polytetrafluoroethylene reactor, add pretreated dry nickel foam, and conduct a hydrothermal reaction at 180°C for 12 hours.

[0040] (3) The hydrothermal product was taken out, washed with ethanol three times, and then dried at 60°C for 30 minutes to obtain the material precursor 2 of titanium dioxide nanowire array supported in situ on a nickel foam substrate.

[0041] (4) ...

Embodiment 3

[0043] A method for preparing a nickel foam substrate in-situ loaded titanium dioxide nanowire array material, the steps are as follows:

[0044] (1) The nickel foam with a width of 1 cm and a length of 4 cm was sequentially immersed in 15 mL of 1 mol / L hydrochloric acid, deionized water, acetone and absolute ethanol, ultrasonically cleaned at 30 °C for 5 min, and placed in Dry in an oven at 60°C until completely dry.

[0045] (2) Mix 10 mL of glycerol, 0.5 mL of tetrabutyl titanate and 20 mL of absolute ethanol at room temperature until a uniform mixture is formed. Then transfer it to a 50 mL polytetrafluoroethylene reactor, add the pretreated dry nickel foam, and conduct a hydrothermal reaction at 180 °C for 12 h.

[0046] (3) The hydrothermal product was taken out, washed three times with ethanol, and dried at 60 °C for 30 min to obtain the precursor 3 of titanium dioxide nanowire array material supported in situ on a nickel foam substrate.

[0047] (4) Put the precursor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com