Mango weighing, grading and sorting device

A sorting device and mango technology, applied in sorting, measuring device, weighing equipment for automatic feeding/discharging, etc., can solve the problem that the size, quality, variety and grade of mango cannot be accurately distinguished, and it is difficult to realize the interests of growers. Maximize, it is difficult to achieve the efficiency of mango sorting, etc., to achieve the effect of reliable sorting function, small footprint, and reliable weight classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

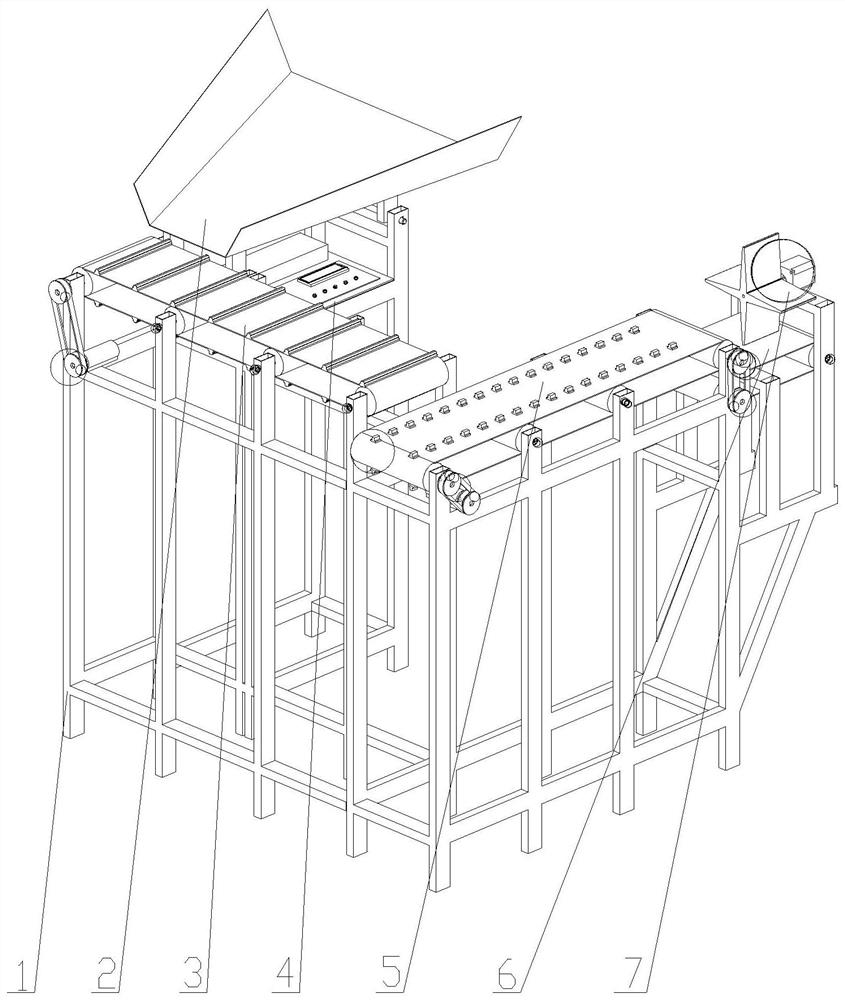

[0035] Embodiment 1 A kind of mango weighing grading and sorting device of the present invention comprises:

[0036] Frame 1, the top is equipped with a feeding station, a conveying station, a weighing station, a sorting station and a control station;

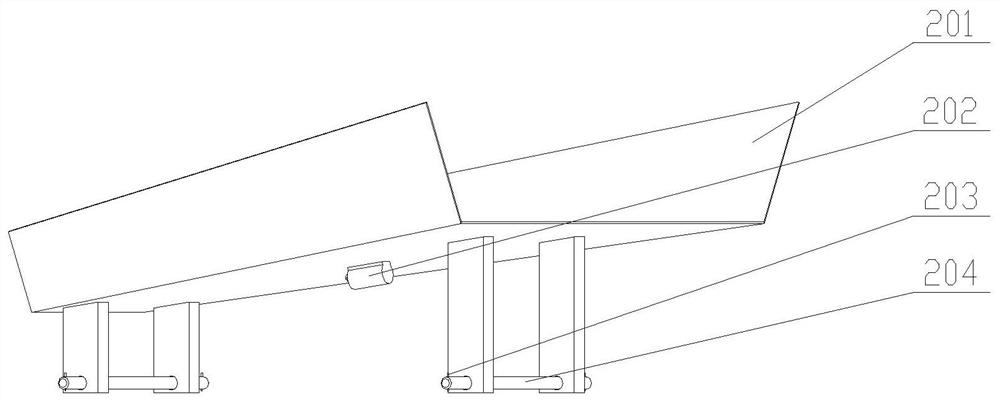

[0037] The feeding mechanism 2 is arranged at the feeding station of the frame, including a feeding funnel 201, a vibrating motor 202 and two sets of sliding support frames, and the bottom of the feeding funnel 201 slides through the sliding support frame 203 Installed at the feeding station of the frame, and the outlet of the feeding funnel 201 is inclined downwards, for the convenience of the mangoes in the feeding funnel 201 falling; the vibration motor 202 is installed on the The bottom of the feeding funnel 201 is used to drive the feeding funnel 201 to vibrate to shake off the mango in it;

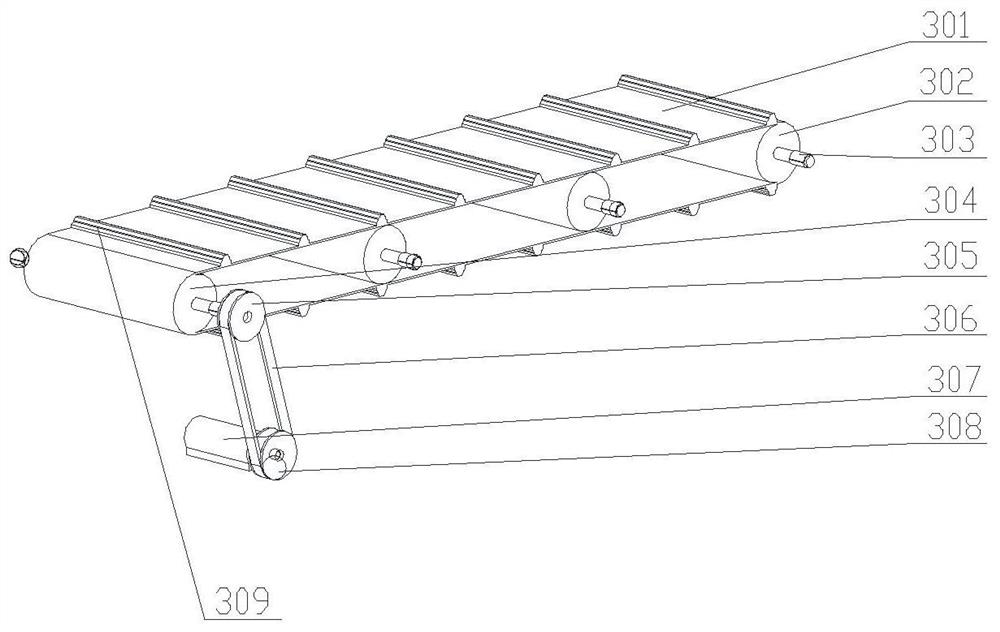

[0038] The conveying mechanism is arranged between the feeding mechanism 2 and the weighing mechanism 6, including the primary card...

Embodiment 2

[0051] Embodiment 2 adopts the method that a kind of mango weighing grading sorting device described in embodiment 1 is sorted mango, comprises the following steps:

[0052] S1 The operator sets the mango weight grading index LOW and HIGH respectively through the control mechanism 4, wherein the LOW index is added and subtracted through the first level control button 406, and the HIGH index is added and subtracted through the second level control button 405;

[0053] S2 presses the tare button 404 to reset the current weight to zero, and calibrates the weighing mechanism 6;

[0054] S3 Put a sufficient amount of mangoes into the feeding hopper 201, and the mangoes are continuously moved to the primary carding transmission mechanism 3 under the action of the vibration motor 202 and gravity. Under the action of the protruding bar 309, the horizontal linear distribution becomes horizontal; at this time, the first driving motor 307 rotates to drive the second pulley 308, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com