Preparation method of synthetic rubber sole

A technology for synthesizing rubber and rubber soles, applied in the field of rubber sole production, can solve the problems of quality impact, rubber sole cutting, complicated operation, etc., and achieve the effects of improving quality, ensuring smoothness, and increasing frictional contact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

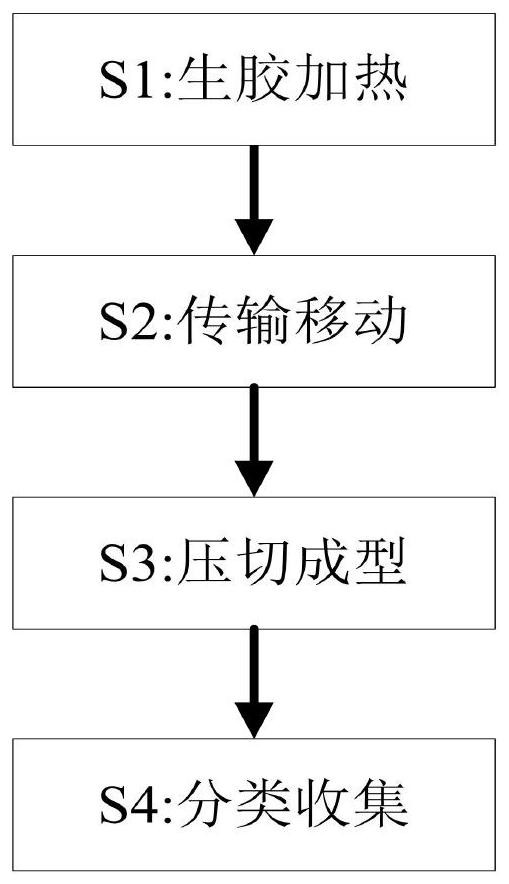

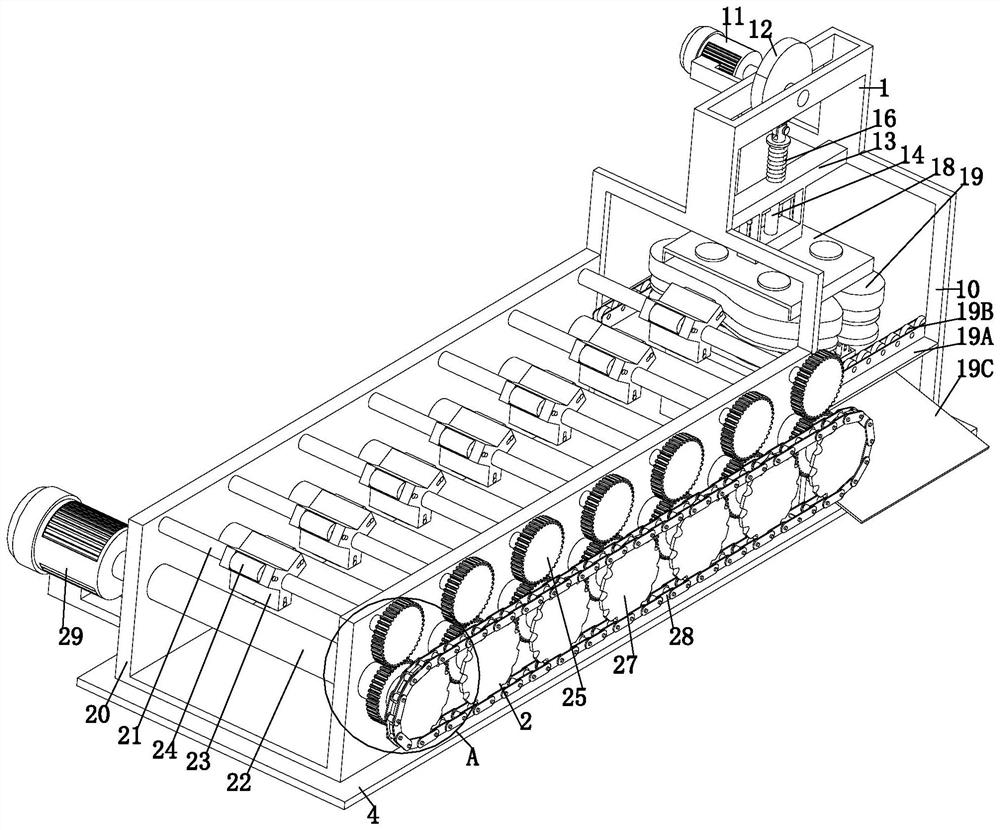

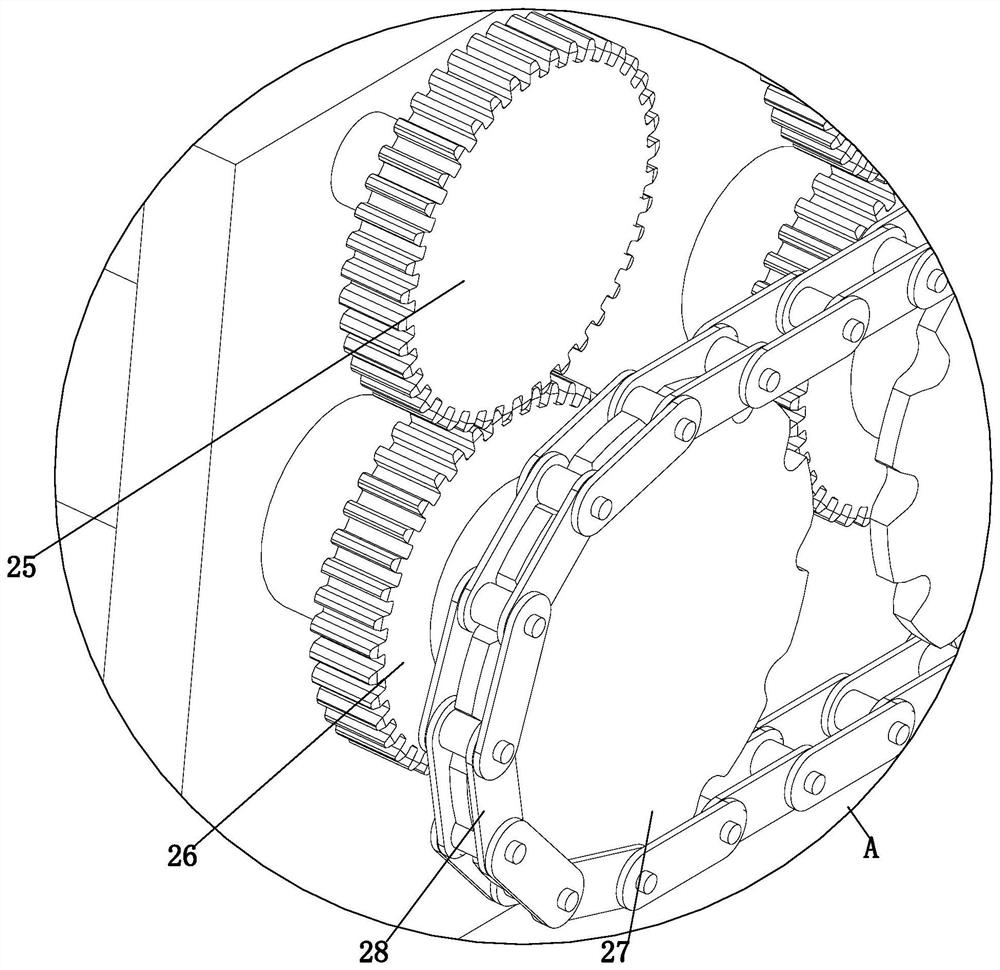

[0032] Such as Figure 1 to Figure 9 Shown, a kind of synthetic rubber sole preparation method, it has used a kind of rubber sole processing equipment, this processing equipment comprises pressure cutting mechanism 1, transmission mechanism 2, delivery mechanism 3 and bottom plate 4, adopts above-mentioned processing equipment to carry out rubber sole The specific method of extrusion cutting is as follows:

[0033] S1. Raw rubber heating: heat the raw rubber through the heating device to soften the rubber and press it into a strip-shaped rubber;

[0034] S2. Transmission movement: transport the heated rubber in S1 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com