A kind of composite fiber and its preparation method, graphene flexible temperature sensing array and its preparation method

A composite fiber and sensing array technology, applied in the direction of thermometers, thermometers, fiber processing, etc. that are directly sensitive to heat-sensitive electrical/magnetic elements, can solve the problem of difficult to achieve both electrical conductivity and strain adaptability, and destroy polymers. Strain adaptability, inability to measure and other problems, to achieve excellent strain adaptability, simple preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

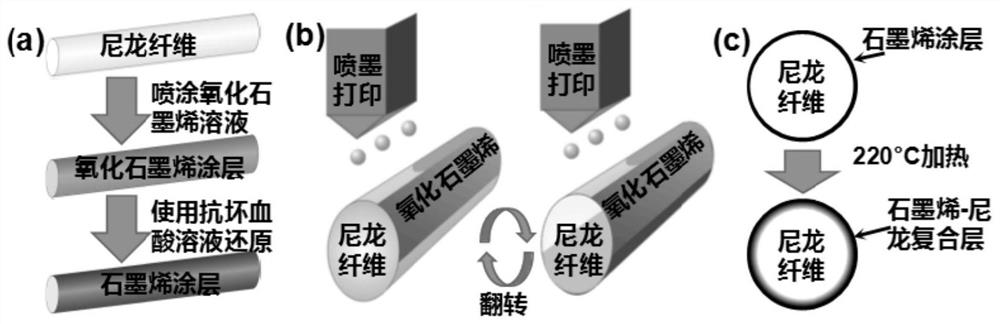

[0056] According to another aspect of the present invention, the present invention also relates to the preparation method of the above-mentioned composite fiber, comprising the following steps:

[0057] The polymer fiber coated with graphene is heated.

[0058] The present invention heats the polymer fiber coated with graphene on the surface, and the graphene coating on the surface and the polymer fiber inside will form a graphene-nylon composite layer. The surface of the graphene-polymer composite fiber is composed of a pure graphene layer, which is the core material that provides electrical conductivity and temperature sensing. The graphene-polymer composite layer under it is between the graphene layer and the polymer fiber layer The joint part; under the graphene-polymer fiber composite layer is the polymer fiber layer, which is the core material that provides strain adaptability.

[0059] Preferably, the heating temperature is the glass transition temperature Tg-(Tg+5)°C ...

Embodiment 1

[0094] A kind of preparation method of graphene-nylon composite fiber, comprises the following steps:

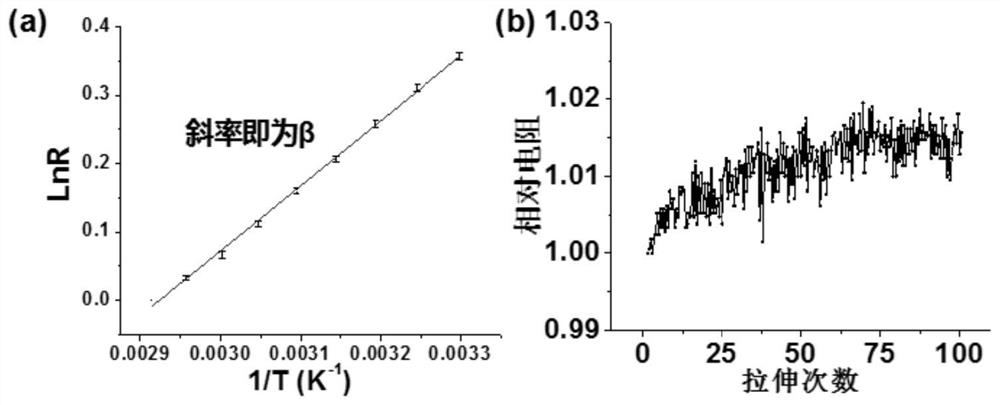

[0095]Take a nylon fiber with a diameter of 300 microns, and use inkjet printing technology to evenly spray an aqueous solution of graphene oxide with a mass concentration of 0.2% on both sides of the nylon fiber. Graphene oxide film: place the nylon wire covered with graphene oxide film in 0.05mol / L ascorbic acid aqueous solution at a constant temperature of 90°C for 60 minutes, so that graphene oxide is reduced to graphene that can conduct electricity and has temperature sensing properties, Then dip the nylon thread covered with graphene in deionized water, wash away the impurities in the graphene, and remove the residual moisture in the graphene at a constant temperature of 70°C for 24h; place the dried graphene-nylon composite fiber in Heating at 220°C for 10 minutes, the graphene coating on the surface and the inner nylon layer will form a graphene-nylon composite layer...

Embodiment 2

[0098] A method for preparing a graphene flexible temperature sensing array, comprising the following steps:

[0099] Prepare 6 graphene-nylon composite fibers obtained in Example 1, 12 silver conductive fibers and a piece of fabric with good flexibility as a flexible base, and the flexible base is a polyester fabric. Such as image 3 As shown, the graphene-nylon composite fiber is first fixed in the fabric laterally by sewing; as Figure 4 As shown, 6 conductive fibers are sewn on the fabric in a horizontal manner, and 6 conductive fibers are sewn on the fabric in a vertical manner; as Figure 5 As shown, at each sensing point, there is a horizontal and a vertical two conductive fibers in contact with the graphene-nylon composite fiber to form two contact points, and the distance between the two contact points is about 1mm to form a 1mm-sized Temperature sensor; outside the temperature sensing point, the conductive fiber should avoid contact with the graphene-nylon composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com