Drilling robot for coal protective layer mining

A protective layer and robot technology, applied in drilling equipment and methods, drilling with liquid/gas jets, drill bits, etc., can solve the problems of small influence range of extraction radius and poor extraction effect, and achieve compact and reliable structure and installation. The effect of easy disassembly and reduced wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

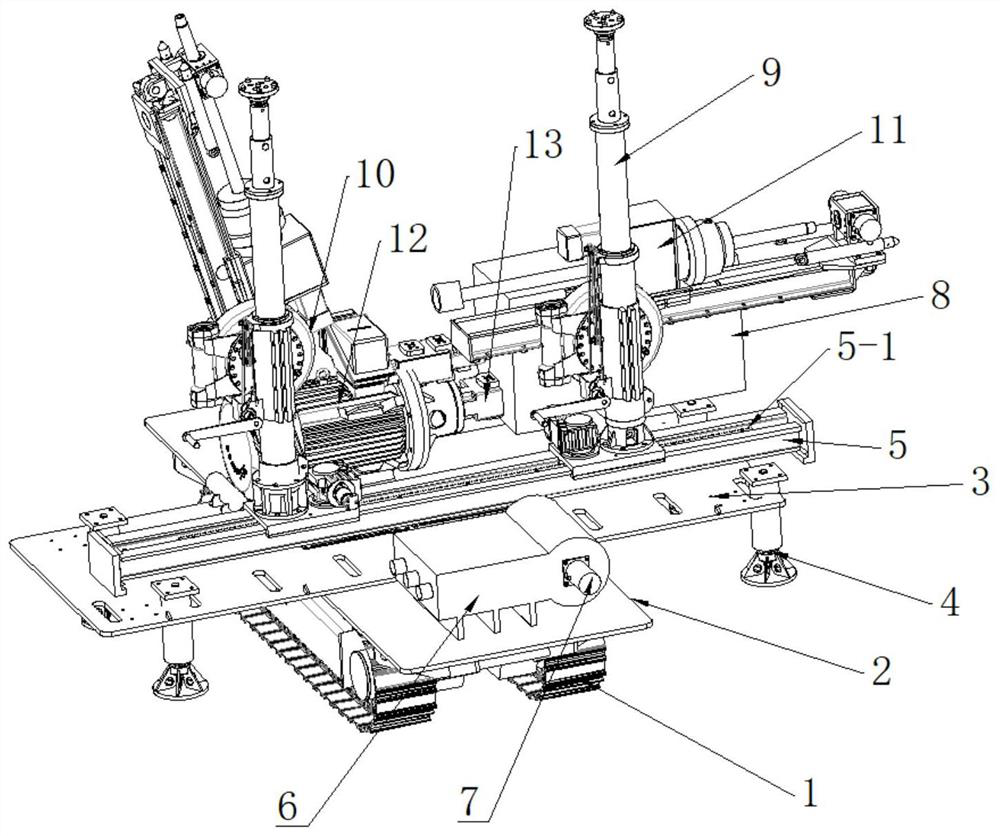

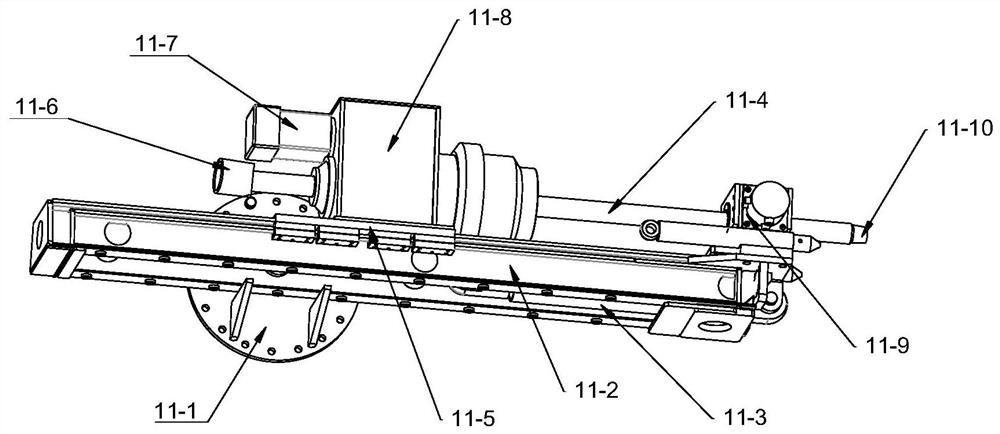

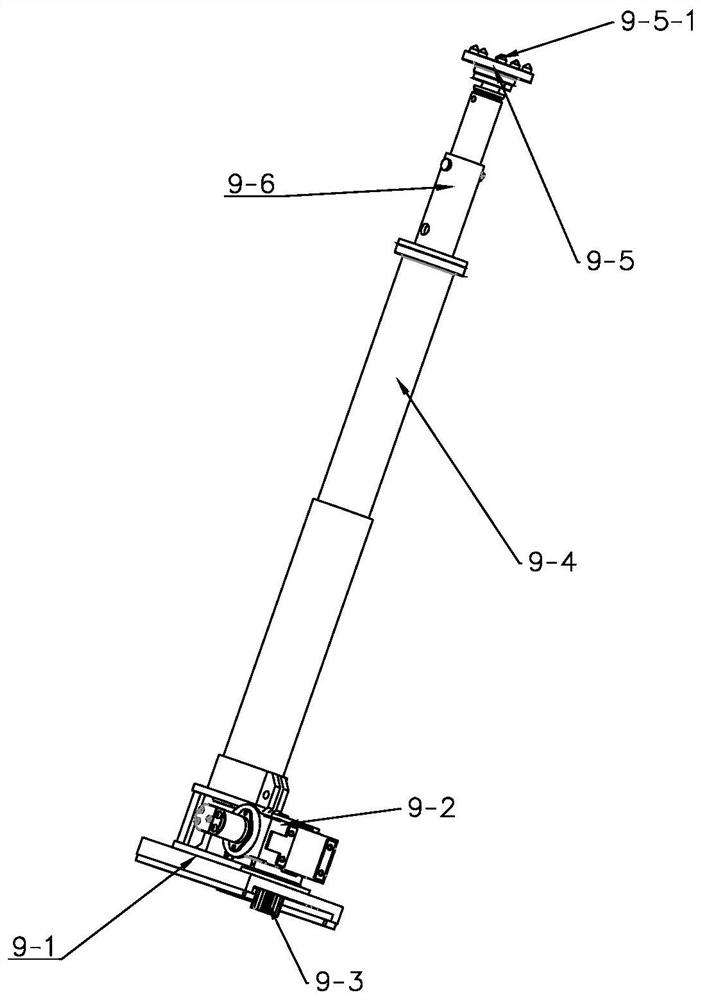

[0022] A kind of drilling robot that is used for mining of coal protection layer of the present invention comprises crawler belt traveling mechanism 1, frame 2, base 3, support column 4, guide rail seat 5, plunger water pump 6, hydraulic motor 17, fuel tank 8, installation Column 9, rotary movement mechanism 10, drilling and reaming mechanism 11, motor 12 and oil pump 13.

[0023] Frame 2 is the link of each component of the drilling and hydraulic reaming pressure relief robot of the present invention. The crawler walking mechanism 1 is installed below the frame 2 for realizing the walking of the drilling and hydraulic reaming pressure relief robot. The plunger water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com