Full-automatic tunnel wet spraying state detection method based on three-dimensional laser radar

A three-dimensional laser and state detection technology, applied in the direction of measuring devices, electromagnetic wave re-radiation, radio wave measurement systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

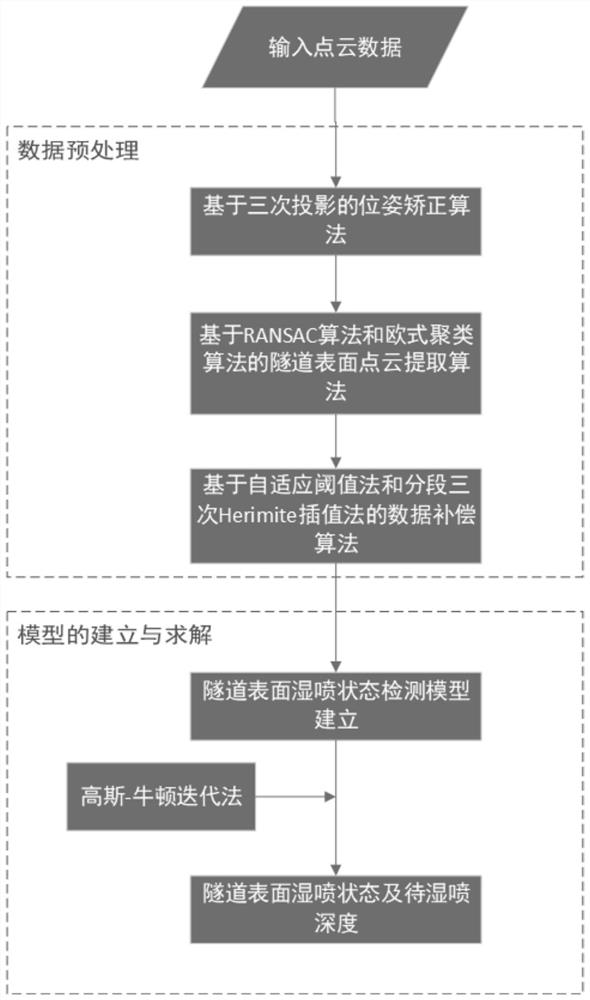

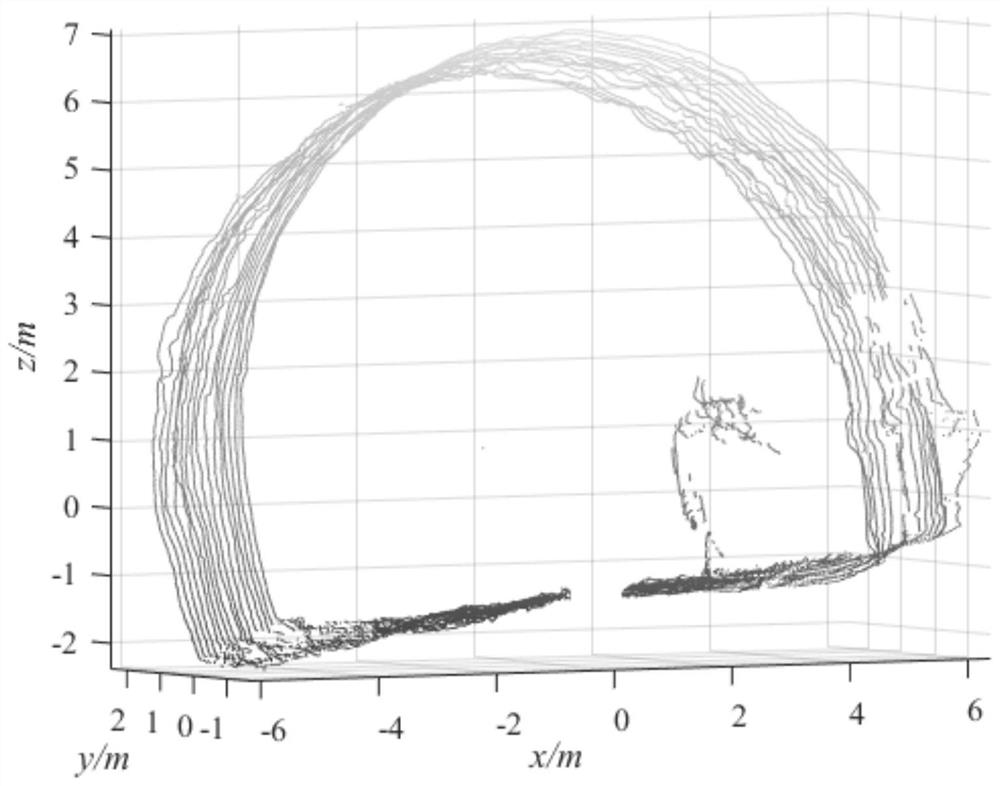

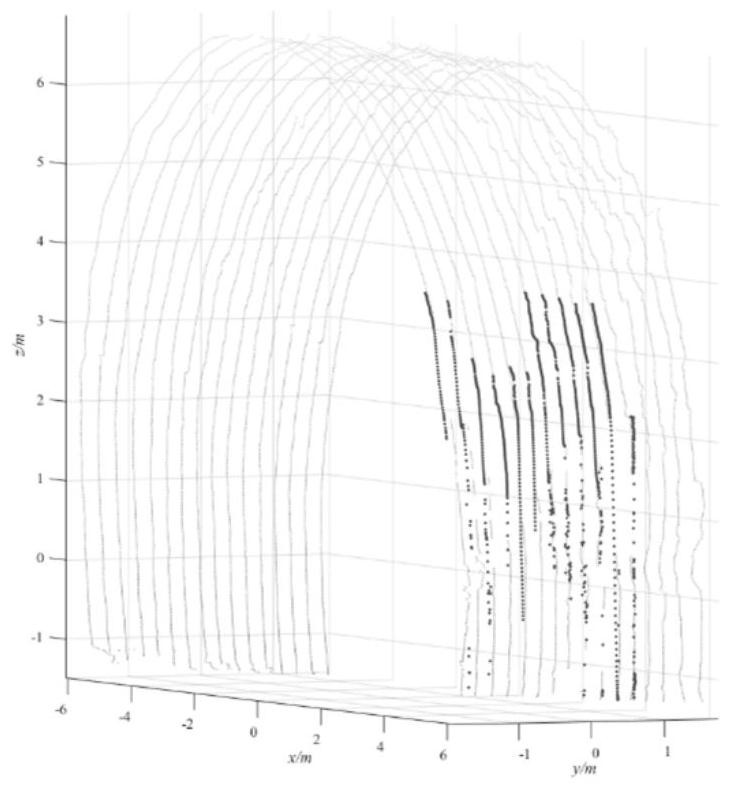

[0066] The step process of this embodiment is as follows figure 1 shown. here to figure 2 The one-frame tunnel point cloud image shown is taken as an example. The fully automatic tunnel wet spraying state detection method based on 3D lidar described in this example includes the following steps:

[0067] S1: as attached figure 2 As shown, the original tunnel point cloud data is tilted due to equipment installation or bumpy road conditions. This embodiment completes automatic pose correction based on the tunnel point cloud data, and uses three projections on the ground point cloud data to obtain the relative position of the point cloud. The relative offset angles on the x-axis, y-axis and z-axis, so as to automatically correct the tilted tunnel point cloud, the specific steps are as follows:

[0068] S101: First,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com