Lightweight design method for large and medium-sized parts based on generative optimization and guided reconfiguration

A lightweight design and generative technology, applied in the field of model design and metal processing and manufacturing, can solve the problems of high risk of processing failure, limited molding size, difficulty in molding large and medium-sized parts, etc., to achieve a high degree of lightweight, processing Low difficulty and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

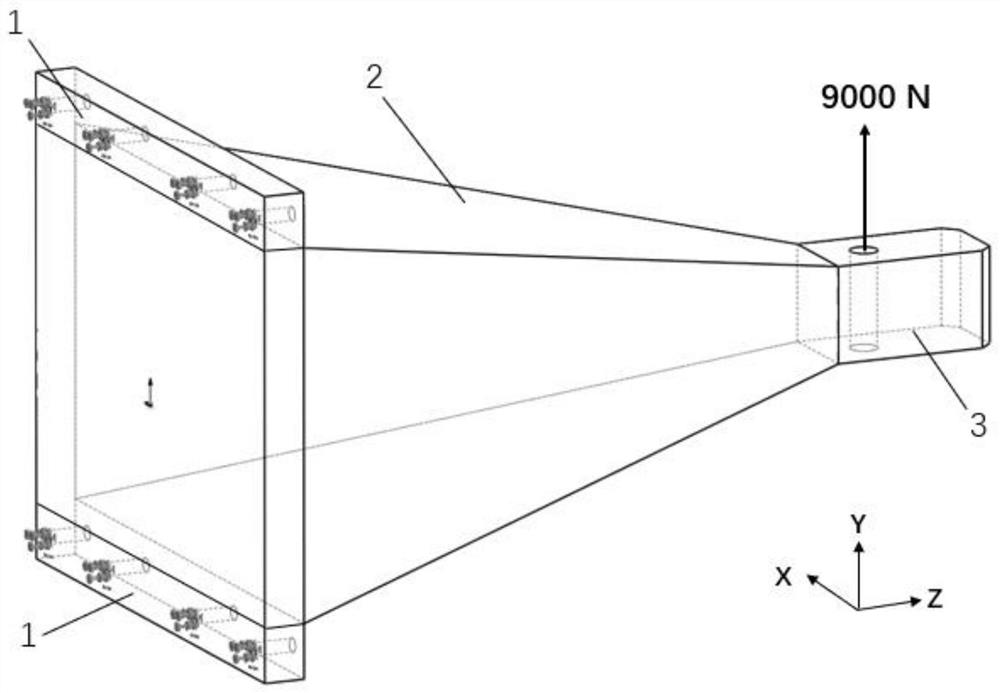

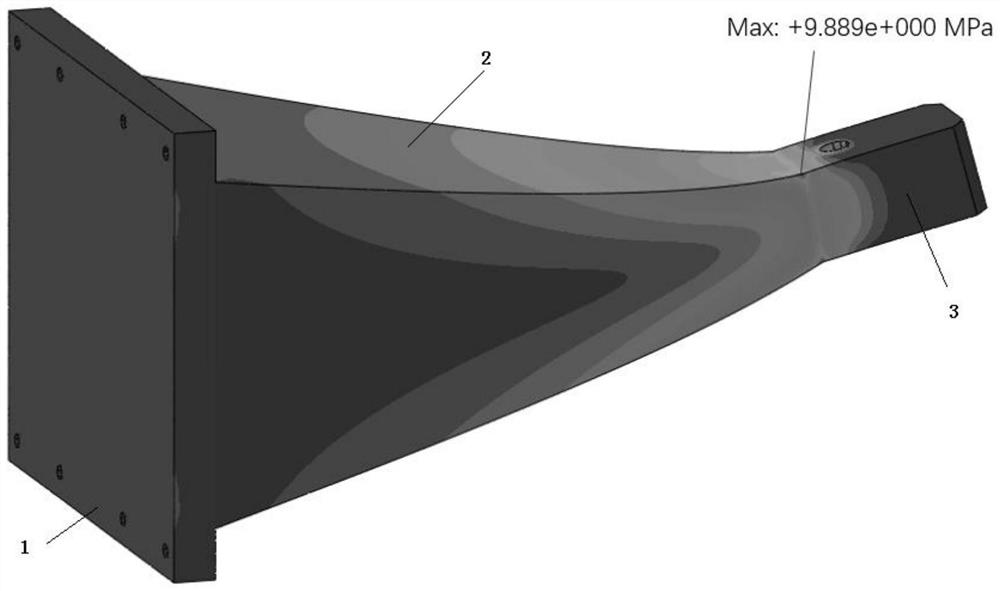

[0071] Below, refer to the attached Picture 1-1 2. Embodiments of the present invention will be described.

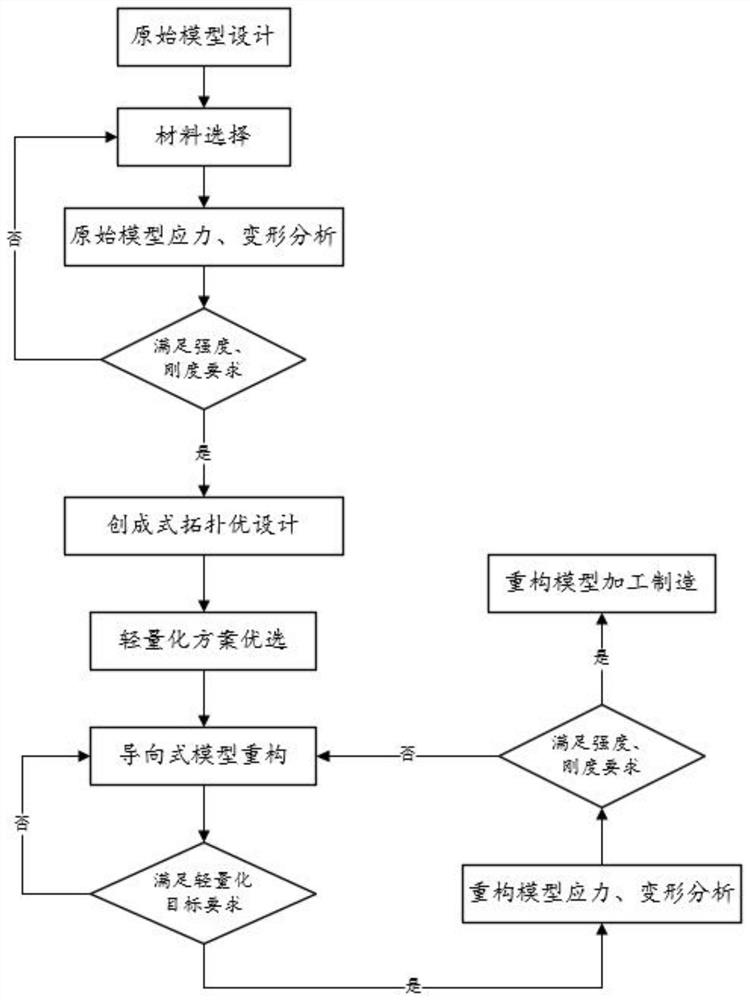

[0072] In order to realize the lightweight design of the original model to the greatest extent, obtain the optimized result model with the best force transmission performance, and avoid the limited molding size of the additive manufacturing (3D printing) process, it is difficult to form large and medium-sized parts, and the processing fails during the accumulation molding process high risk, high manufacturing cost and other problems, as well as problems such as holes and shrinkage porosity that are prone to occur when the topology optimization structure is formed by casting technology, the present invention proposes a large and medium-sized part based on generative optimization and guided reconstruction lightweight design approach. Based on the shape and size of the optimal plan result model, guided by the traditional forming process, the reverse modeling technology i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com