A lithium metal battery with a curved lithium sheet negative electrode

A lithium metal battery, curved surface technology, applied in the direction of lithium battery, negative electrode, battery electrode, etc., can solve the problems of reducing cycle efficiency and service life, low coulombic efficiency of lithium battery, lithium metal powder or dendrite, etc. Large effective surface area, enhanced electrochemical reaction kinetics, and the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

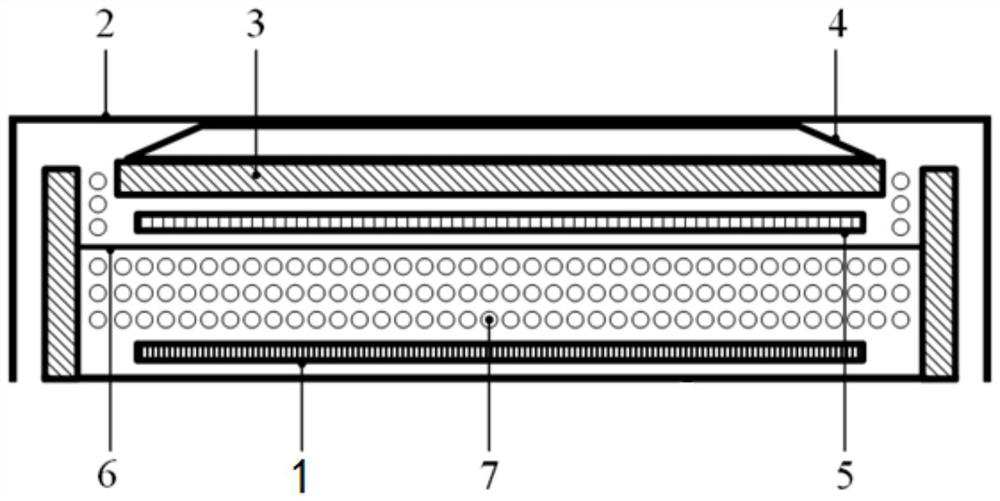

[0034] like figure 1 As shown, a lithium metal battery with a curved lithium sheet negative electrode includes a battery case 2, a diaphragm 6 is arranged inside the battery case 2, and the two ends of the diaphragm 6 are respectively connected to the middle of the battery case 2, and the diaphragm 6 and the battery case 2 There is a first cavity between one end, a second cavity is set between the diaphragm 6 and the other end of the battery case 2, and an electrode piece 1 is arranged in the first cavity, and the electrode piece 1 abuts against the battery case 2 One end, the second cavity is provided with a battery negative pole 5, the two ends of the battery negative pole 5 are respectively abutted against the diaphragm 6 and the other end of the battery case 2, the battery negative pole 5 is made of a curved lithium sheet, the first cavity and the second cavity The cavity is filled with electrolyte solution 7 , and the electrode piece 1 and the negative electrode 5 of the ...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that the electrode sheet 1 is made of a curved lithium sheet. That is, both the electrode sheet 1 and the negative electrode 5 of the lithium symmetric battery are made of curved lithium sheets.

[0052] The constant current cycle performance test of the lithium symmetric battery of this embodiment was carried out by using the LAND CT2001A battery test system.

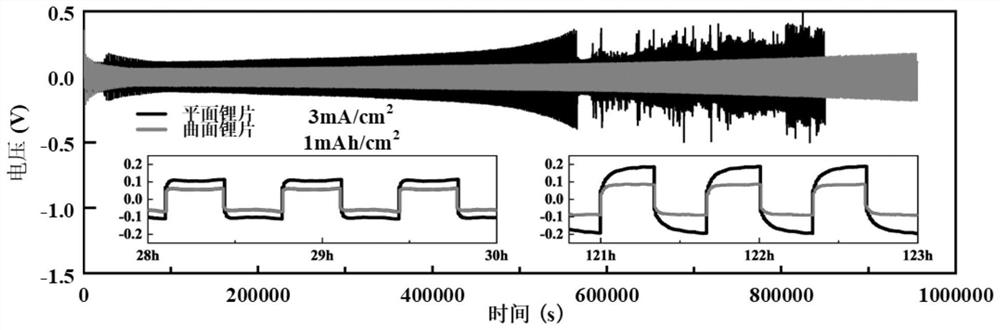

[0053] from image 3 It can be seen that both the electrode sheet 1 and the negative electrode 5 of the battery adopt a lithium symmetric battery with a curved surface lithium sheet at 3mA / cm 2 current density, 1mAh / cm 2 After cycling for about 900,000 seconds under the deposition capacity, the polarization voltage is only 0.16V. Under the same conditions, the polarization voltage of the lithium symmetric battery based on the planar lithium sheet has reached 0.16V after about 340,000 seconds of cycling. In the subsequent cycles, the polarization volta...

Embodiment 3

[0056] The preparation method of the curved lithium sheet is to make the planar lithium sheet with a curved surface by embossing and rolling.

[0057] Optionally, the preparation method of the curved lithium sheet comprises the following steps,

[0058] Prepare a curved surface mold in the shape of the required curved surface lithium sheet; spread the polypropylene film and the curved surface mold on the surface of the flat lithium sheet in sequence, and clamp the curved surface mold, polypropylene film and flat lithium sheet with a clamp; press the curved surface mold with a pressure device, Make the planar lithium sheet form the same curved surface as the curved surface mold; take out the curved surface mold and the polypropylene film to obtain the required curved surface lithium sheet.

[0059] Specifically, a layer of polypropylene film was spread on the surface of the flat lithium sheet, and placed in the center of the jaws of the precision drilling jig, and then the curv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com