Ultrahigh repetition frequency femtosecond fiber laser system applied to material micromachining

A femtosecond fiber and laser system technology, applied in the field of laser technology and nonlinear optics, can solve the problem of laser output pulse width, pulse coherence, pulse signal-to-noise ratio, poor pulse coherence time stability, and large pulse amplitude and phase noise. and other problems, to achieve the effect of strong anti-environmental interference ability, strong reliability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments:

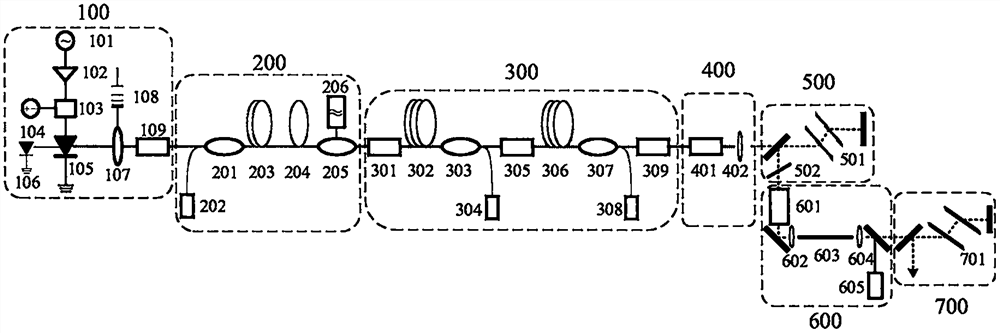

[0024] figure 1 It is a schematic structural diagram of an ultra-high repetition frequency femtosecond fiber laser system applied to material microprocessing in an embodiment of the present invention.

[0025] As shown in Figure 1, an ultra-high repetition frequency femtosecond fiber laser system applied to material microprocessing in this embodiment consists of a gain switch picosecond seed source 100 according to the order of the optical path, a signal light regeneration system 200, and a fiber pre-amplifier 300, a pulse picker 400, a pulse pre-chirp shaper 500, an optical fiber power amplifier 600 and a pulse compressor 700. in:

[0026] Gain switch semiconductor laser seed source 100 includes: electric pulse generator 101, signal amplif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com