A kind of glass fiber reinforced plastic cable conduit and its processing technology

A technology of glass fiber tubes and reinforced plastics, applied in the direction of electrical components, etc., can solve problems such as broken conduits and insufficient axial strength of cable conduits, achieve good protection, improve overall mechanical strength, enhance axial strength and transverse strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

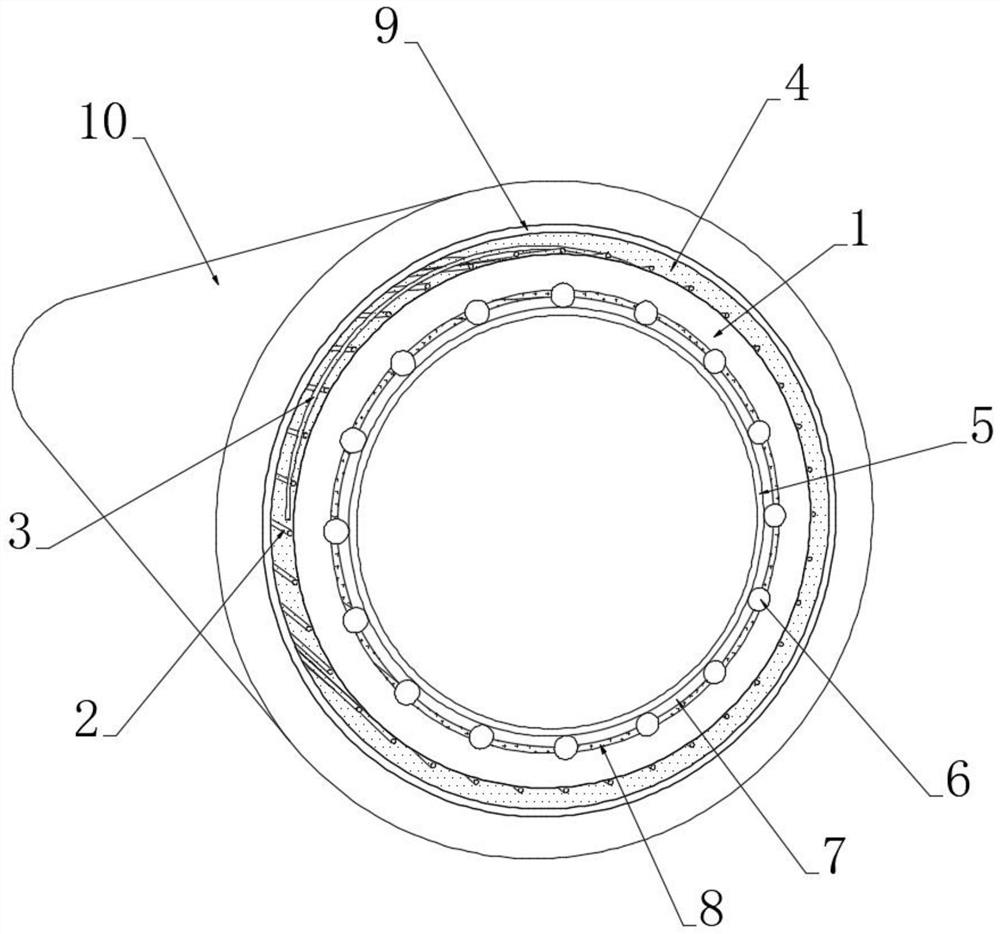

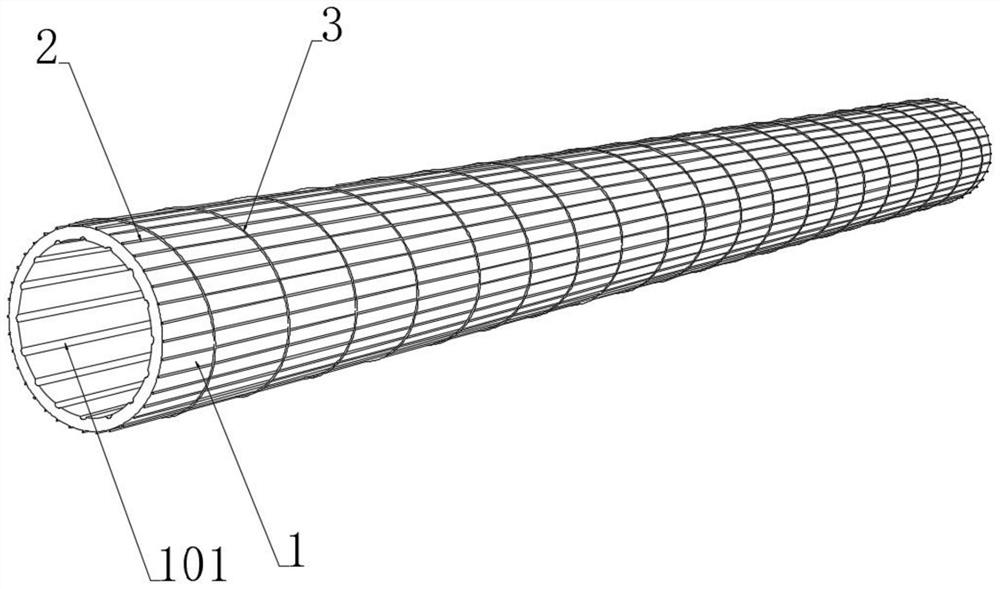

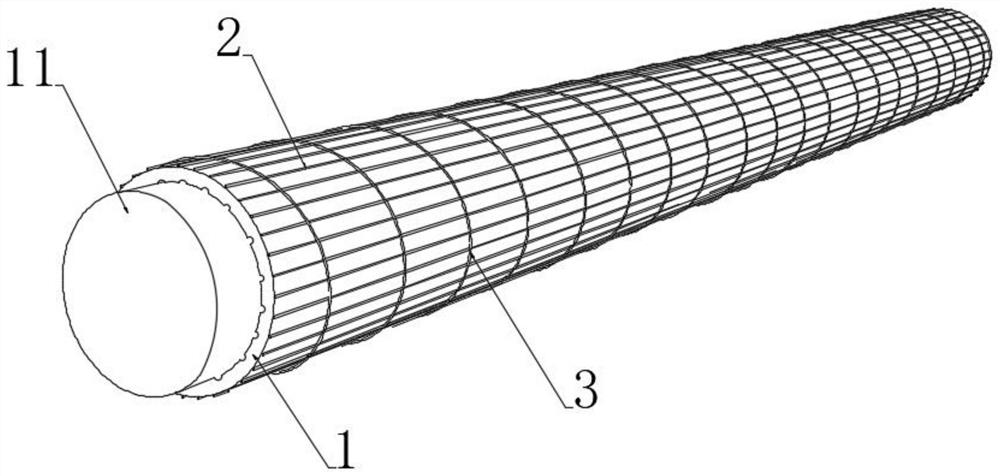

[0042] see Figure 1-2 , a glass fiber reinforced plastic cable conduit, comprising an inner sheath 1, a plurality of axial fibers 2 are annularly distributed on the outer side wall of the inner sheath 1, and the axial lengths of the plurality of axial fibers 2 and the inner sheath 1 are the same size Consistently, the outer side wall of the inner sheath 1 is provided with transverse fibers 3 located outside the plurality of axial fibers 2, the transverse fibers 3 are spirally wound around the outer side of the inner sheath 1, and the axial fibers 2 and the transverse fibers 3 are both It is made of glass fiber, and the outer diameter of the axial fiber 2 and the transverse fiber 3 is 2-4 mm. The transverse fiber 3 that surrounds in a spiral shape plays a role in positioning a plurality of annularly distributed axial fibers 2. The oriented axial fibers 2 cooperate with the annularly arranged transverse fibers 3 to enhance the axial strength of the inner sheath 1. The outer end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com