Preparation process of silky soft printing small coating film for sanitary napkins

A preparation process and technology for sanitary napkins, which is applied in the field of preparation of silky and soft printed small envelopes for sanitary napkins, which can solve the problems of hard hand feeling, poor printing effect, and excessive waste discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

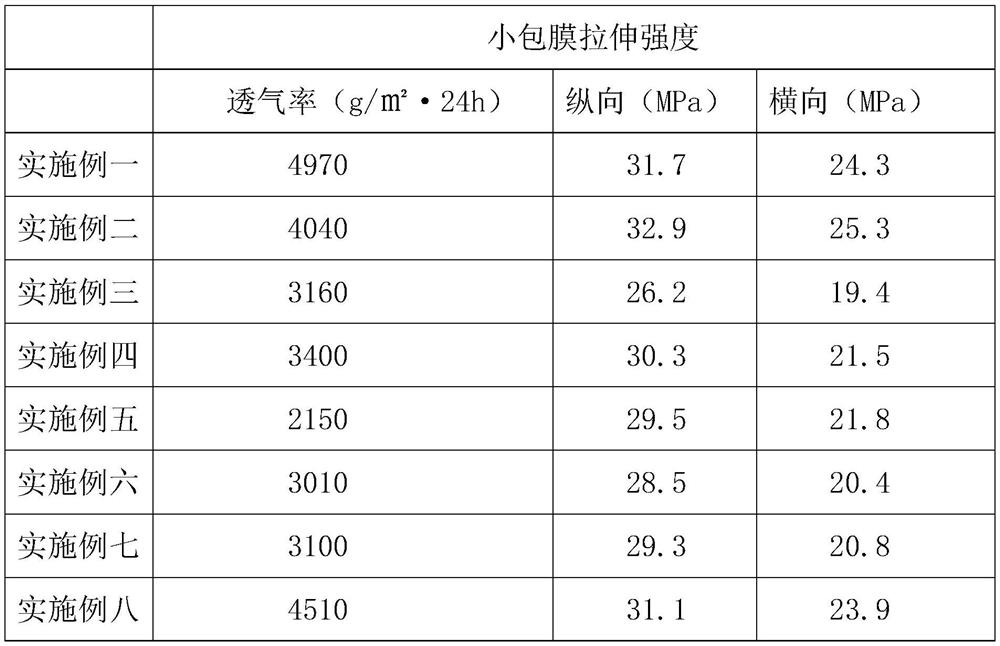

Embodiment 1

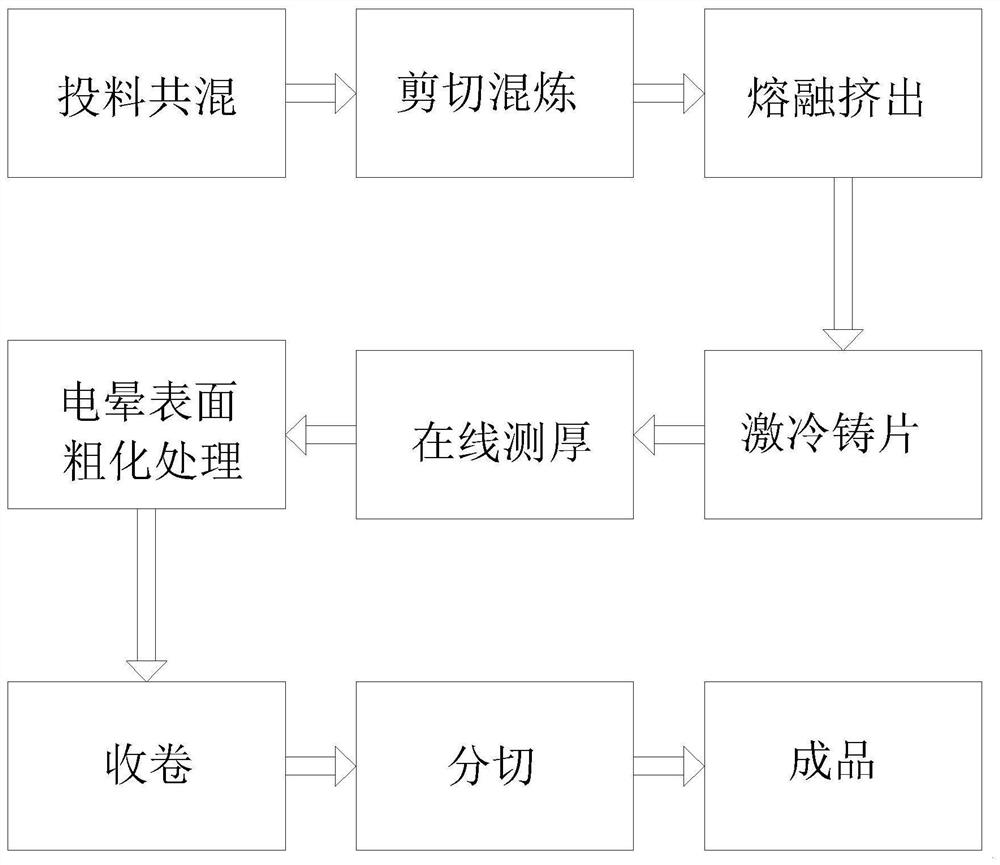

[0029]The present invention provides a technical solution: a sanitary napkin for silk soft printing small envelope preparation process, the production process includes the following steps:

[0030]S1: Material Selection: Polyethylene 55%; antibacterial pellets 2%; antioxidant 0.1%; PE hole membrane penetration 4%; polyolefin-based copolymer resin composition 30%; thermoplastic elastomer particles 4%; soft function 6% of sexual pages; polyethylene in S1 is a metallocene linear polyethylene.

[0031]S2: Material blend: Pour the selected material into the mixer, stir mix, mix between the original, the mixture is a vertical mixer, and the mixing machine is 200R / min, The stirring time was 15 minutes.

[0032]S3: Shear kissant: Pour the material uniform in S2 into the mixer, the mixer produces a large shear force, cut the material high-speed shear, so that the material is fast in the kneaders Flow, accelerate the kneading process, forming a high temperature fluid after shearing kneading, the tem...

Embodiment 2

[0040]Based on the first example, the present invention provides a technical solution: a sanitary napkin for silk soft printing small package film preparation processes, and the production process includes the following steps:

[0041]S1: Material Selection: Polyethylene 60%; 3% of antibacterial pellets; antioxidants 0.15%; PE punch membrane penetrant 4.2%; polyolefin-based copolymer resin composition 35%; thermoplastic elastomer particles 6%; Soft function 8% of sexual pellets; polyethylene in S1 is a metallocene linear polyethylene.

[0042]S2: Material Common: Pour the selected material into the mixer, stir mix, mix between the original, the mixture is a vertical mixer, and the mixing machine is 220 r / min, The stirring time was 18 minutes.

[0043]S3: Shear kissant: Pour the material uniform in S2 into the mixer, the mixer produces a large shear force, cut the material high-speed shear, so that the material is fast in the kneaders Flow, accelerate the kneading process, forming a high te...

Embodiment 3

[0051]The present invention provides a technical solution: a sanitary napkin for silk soft printing small envelope preparation process, the production process includes the following steps:

[0052]S1: Material Selection: Polyethylene 70%; 5% of antibacterial parenchula; antioxidant 0.2%; PE hole membrane penetrant 4%; polyolefin-based copolymer resin composition 40%; thermoplastic elastomer particles; soft function 8% of sexual diet; polyethylene is a metallocene linear polyethylene.

[0053]S2: Material blend: Pour the selected material into the mixer, stir mix, mix between the original, the mixture is a vertical mixer, and the mixing machine is 200R / min, The stirring time was 15 minutes.

[0054]S3: Shear kissant: Pour the material uniform in S2 into the mixer, the mixer produces a large shear force, cut the material high-speed shear, so that the material is fast in the kneaders Flow, accelerate the mixing process, forming a high temperature fluid after shearing kneading, the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com