Method for preparing activated char from bamboo material

A technology for preparing activated carbon and raw materials, which is applied in the field of activated carbon, can solve problems such as uninvolved and undisclosed chemical methods, and achieve the effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

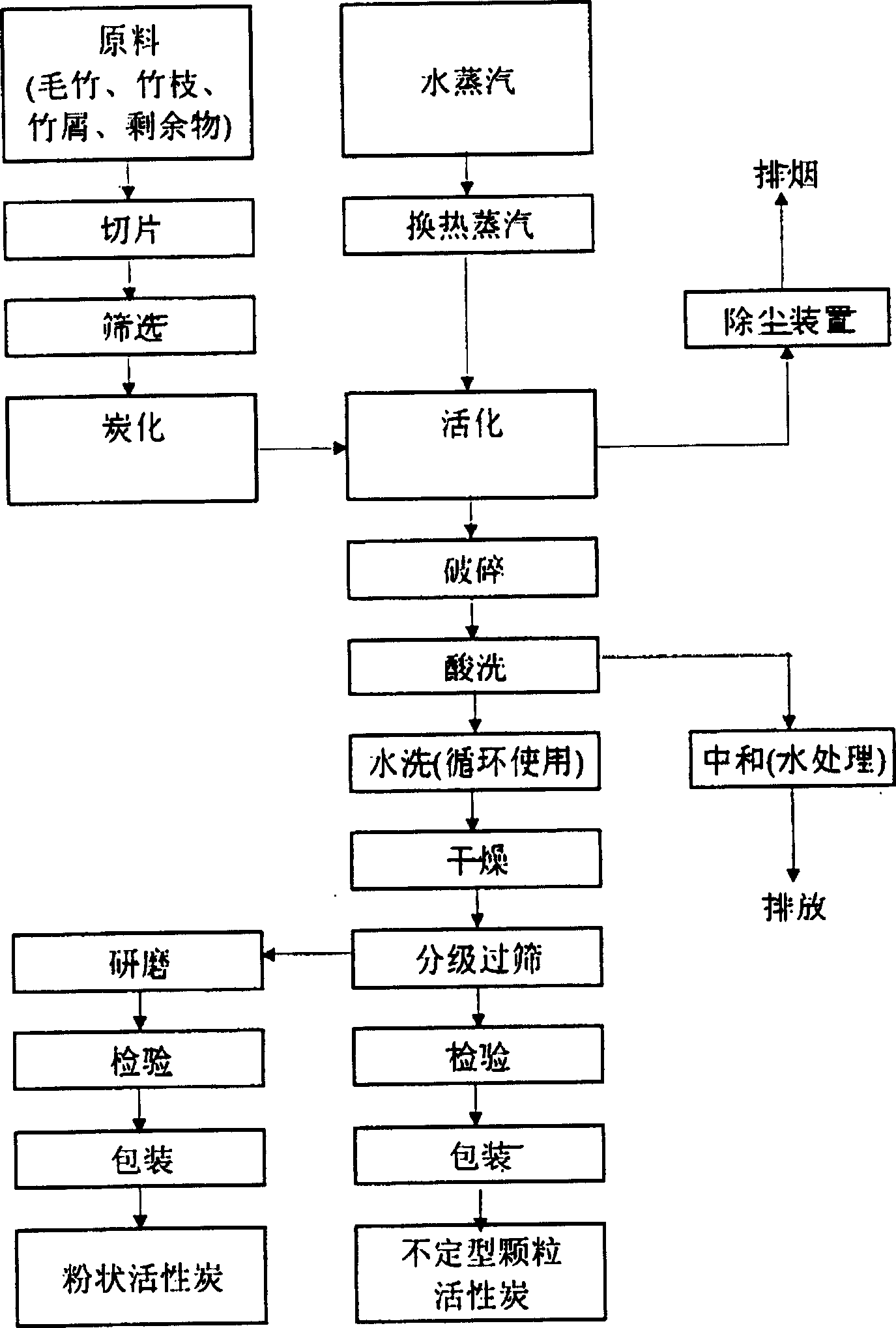

[0044] (1) Select 10 tons of bamboo product residues, cut them into 0.5cm×10cm, screen out the debris, and obtain 9.5 tons of 0.5cm×10cm materials. Put the screened materials into the vertical carbonization furnace, feed 500kg each time, discharge once every hour, and feed while discharging.

[0045] (2) Carry out low-temperature dry distillation carbonization of bamboo raw materials in a carbonization furnace, and the dry distillation carbonization temperature is 450 ° C; after carbonization, it took about 20 hours to obtain 2.80 tons of carbonized materials, and measured technical parameters: volatile matter 23.80%, ash content 1.80 %, moisture 2.60%, fixed carbon 71.80%.

[0046] (3) In the presence of trace oxygen, put the carbonized carbonized material into the activation furnace, and activate it with superheated steam at high temperature. The activation temperature is 765°C; the activation time is 7 hours, and 2.8 tons of carbonized material are used together. 14 hours ...

Embodiment 2

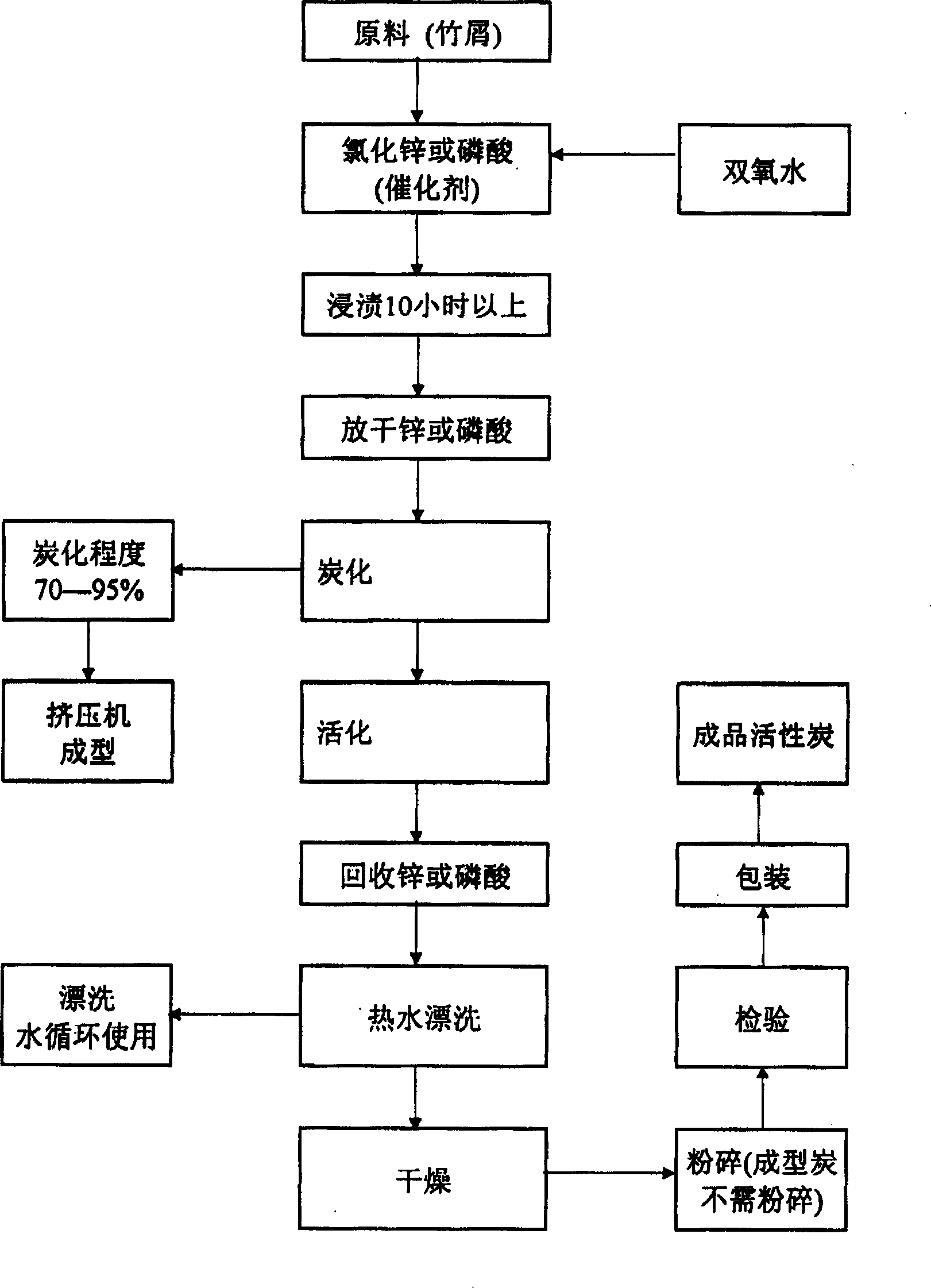

[0051]Bamboo chips are screened and dried until the water content is less than 30%. 1 ton of the treated bamboo chips is obtained, impregnated with a mixed solution of zinc chloride and hydrogen peroxide, added with 15 kg of hydrogen peroxide and 95 kg of zinc chloride, and soaked for 10 hours.

[0052] Put the impregnated bamboo chips into a flat furnace, the temperature is controlled at 320°C, carbonized for 60 minutes, then heated up to 460°C, and activated for 150 minutes. After the activation is completed, the material is discharged, and then the activated material is put into the recovery tank, and the residual zinc chloride in the activated material is dissolved by adding water to recover the zinc chloride until the activated material in the pool does not contain zinc chloride.

[0053] Move the recovered activated material into the rinsing tank, rinse it with hot water for six times, then dry it and grind it. Get bamboo powdery activated carbon 295kg, obtain following ...

Embodiment 3

[0055] Bamboo chips are screened and dried until the water content is less than 30%. 1 ton of the treated bamboo chips is obtained, impregnated with a mixture of phosphoric acid and hydrogen peroxide, and soaked for 12 hours by adding 20 kg of hydrogen peroxide and 80 kg of phosphoric acid.

[0056] Put the impregnated bamboo shavings into a flat furnace, control the temperature at 320°C, carbonize for 60 minutes, then raise the temperature to 460°C, and activate for 210 minutes. After the activation is completed, the material is discharged, and then the activated material is put into the recovery tank, and the residual phosphoric acid in the activated material is heated to dissolve, so as to recover the phosphoric acid until the activated material in the pool does not contain phosphoric acid.

[0057] Move the recovered activated material into the rinsing tank, rinse it with hot water for six times, then dry it and grind it. Get bamboo powdery gac 210kg, get following technic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com