Method for preparing supercapacitor electrode material from perilla-based activated carbon and application

A technology for preparing supercapacitors and activated carbon, applied in the field of electrochemistry, can solve the problems of secondary pollution and waste of resources, and achieve the effect of low cost and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Wash the perilla with deionized water, dry it in an oven at 105°C for 12 hours, take it out, crush it and save it for later use; put the perilla powder into a tube-type resistance furnace, and heat it to 600°C at a heating rate of 5°C / min , and kept at this temperature for 60 minutes, during which nitrogen protection was passed, and after cooling to room temperature, the perilla biochar was obtained.

[0034] Mix analytically pure potassium hydroxide and perilla biochar in a mass ratio of 1:1, add a small amount of deionized water, place the mixture in a tube-type resistance furnace, heat it to 800 °C at a heating rate of 5 °C / min, and The temperature was kept at this temperature for 1 h, during which the nitrogen was protected, and the product was taken out after cooling to room temperature.

[0035] Put the product in (V 浓盐酸 :V 去离子水 =1:9) in dilute hydrochloric acid, ultrasonic treatment for 1h, ultrasonic power 70W, after filtration, the product was boiled and wash...

Embodiment 2

[0037] Wash the perilla with deionized water, dry it in an oven at 105°C for 12 hours, take it out, crush it and save it for later use; put the perilla powder into a tube-type resistance furnace, and heat it to 600°C at a heating rate of 5°C / min , and kept at this temperature for 60 minutes, during which nitrogen protection was passed, and after cooling to room temperature, the perilla biochar was obtained.

[0038] Mix analytically pure potassium hydroxide and perilla biochar at a mass ratio of 2:1, add a small amount of deionized water, place the mixture in a tube-type resistance furnace, heat it to 800 °C at a heating rate of 5 °C / min, and The temperature was kept at this temperature for 1 h, during which the nitrogen was protected, and the product was taken out after cooling to room temperature.

[0039] Put the product in (V 浓盐酸 :V 去离子水 =1:9) in dilute hydrochloric acid, ultrasonic treatment for 1h, ultrasonic power 70W, after filtration, the product was boiled and wash...

Embodiment 3

[0041] Wash the perilla with deionized water, dry it in an oven at 105°C for 12 hours, take it out, crush it and save it for later use; put the perilla powder into a tube-type resistance furnace, and heat it to 600°C at a heating rate of 5°C / min , and kept at this temperature for 60 minutes, during which nitrogen protection was passed, and after cooling to room temperature, the perilla biochar was obtained.

[0042]Mix analytically pure potassium hydroxide and perilla biochar in a mass ratio of 3:1, add a small amount of deionized water, place the mixture in a tube-type resistance furnace, heat it to 800 °C at a heating rate of 5 °C / min, and The temperature was kept at this temperature for 1 h, during which the nitrogen was protected, and the product was taken out after cooling to room temperature.

[0043] Put the product in (V 浓盐酸 :V 去离子水 =1:9) in dilute hydrochloric acid, ultrasonic treatment for 1h, ultrasonic power 70W, after filtration, the product was boiled and washe...

PUM

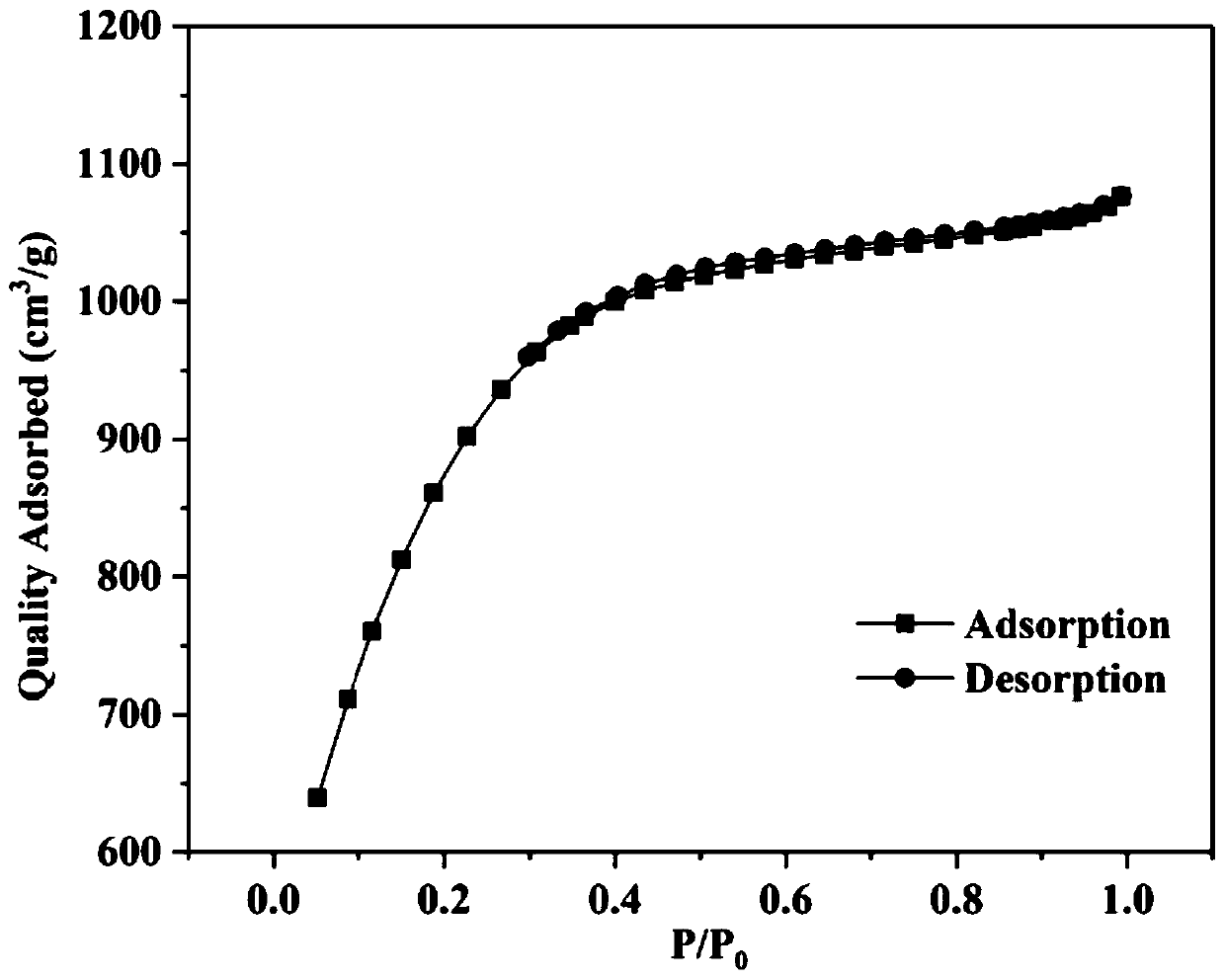

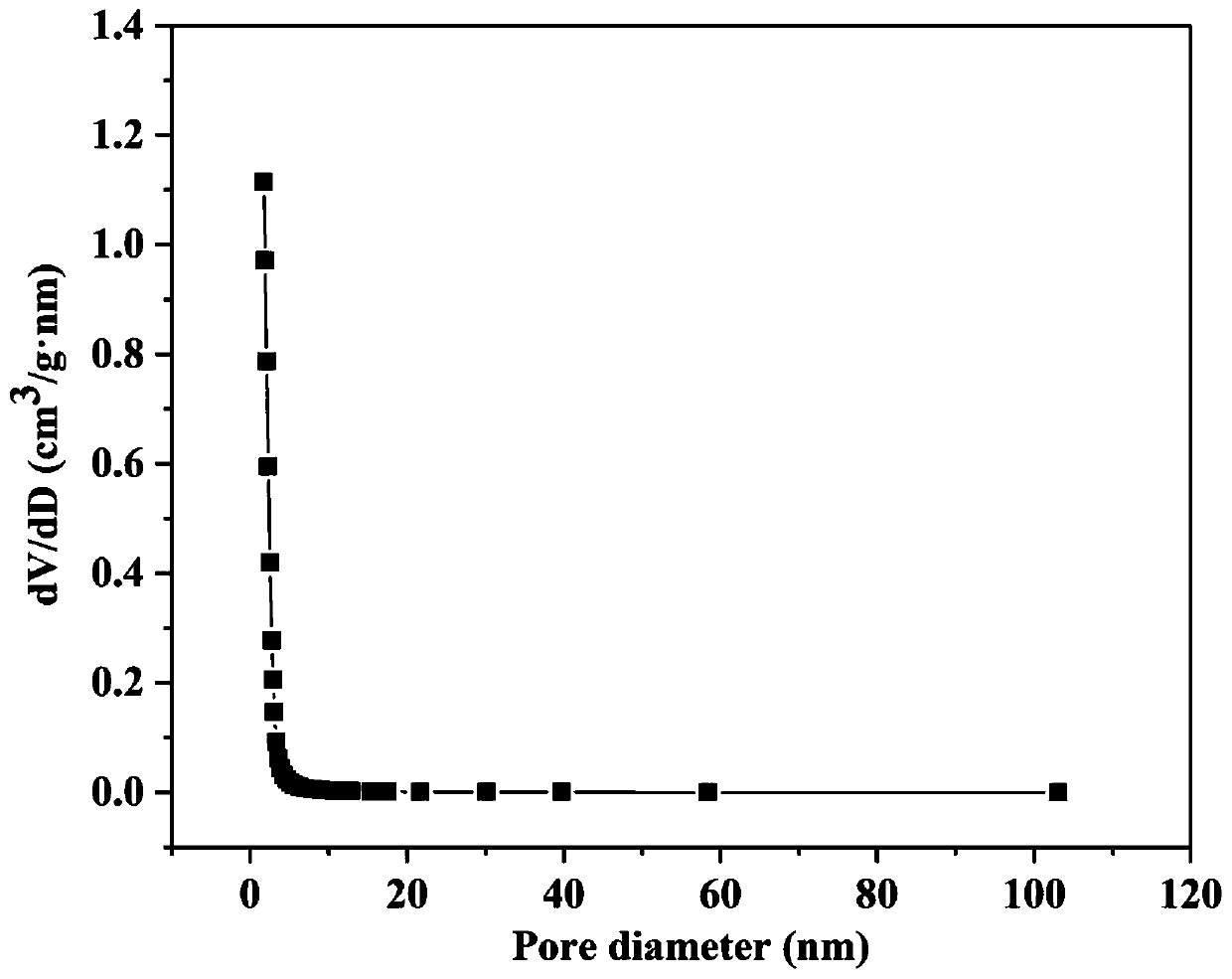

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com