Novel servo press control method

A technology of servo presses and control methods, which is applied to presses, manufacturing tools, etc., and can solve problems such as large amount of calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A further description of the present invention will be given below in conjunction with the accompanying drawings and specific embodiments.

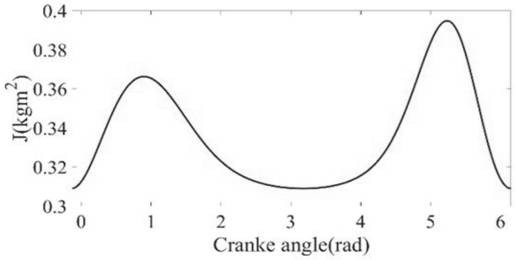

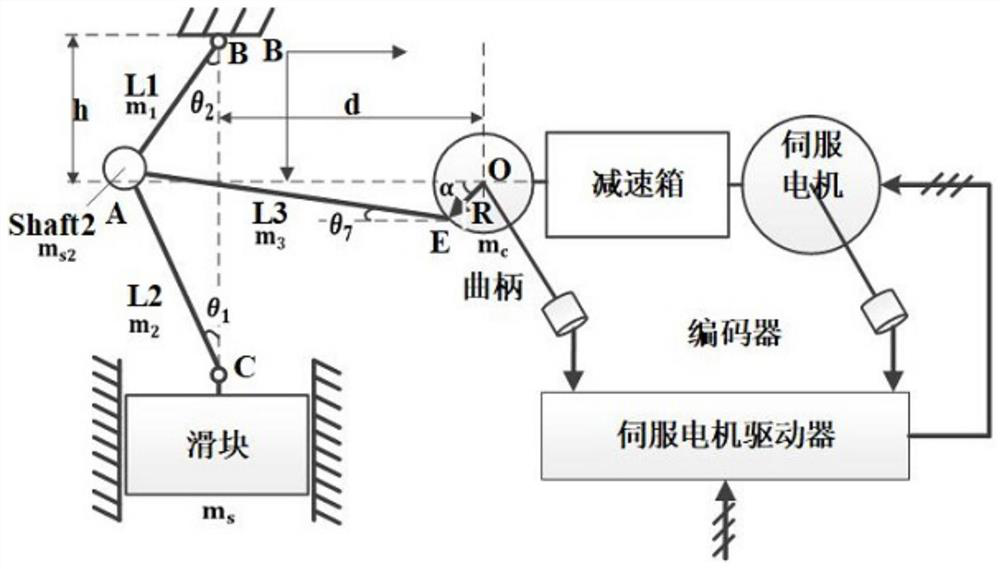

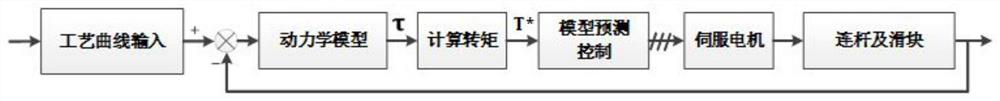

[0033] This embodiment proposes a brand-new control strategy for the servo press, and directly extracts the data in the simulation process for analysis and modeling to complete the control of the motor drive system of the servo press.

[0034] This embodiment adopts a data-driven control strategy based on the Koopman operator. The scheme includes three parts, namely servo press drive system, Koopman analysis and dynamic mode decomposition. Specific steps are as follows:

[0035] 1) The high-voltage pulse of the PWM of the servo press drive system controls the rotation of the motor. Here, a total of 8 switching states of the PWM pulse in the two-level three-phase inverter are selected as the input u of the system, including two 0 voltages Lost switch status. The purpose is to simplify the online calculation method in the prior ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com