Special lubricating liquid for active metal processing and preparation method thereof

A technology of active metals and lubricating fluids, applied in the field of lubricating fluids, can solve problems such as unmeasured economic losses, equipment damage, explosions, etc., and achieve the effects of small power loss, avoiding explosions, and safe production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

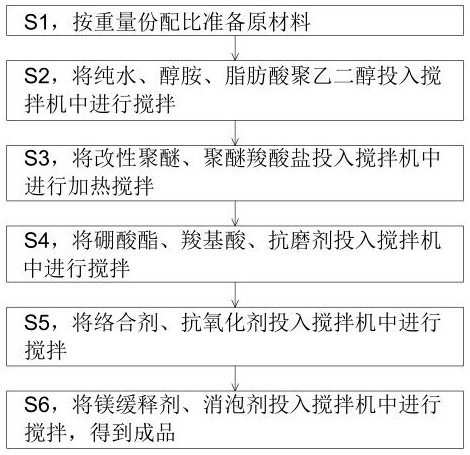

Method used

Image

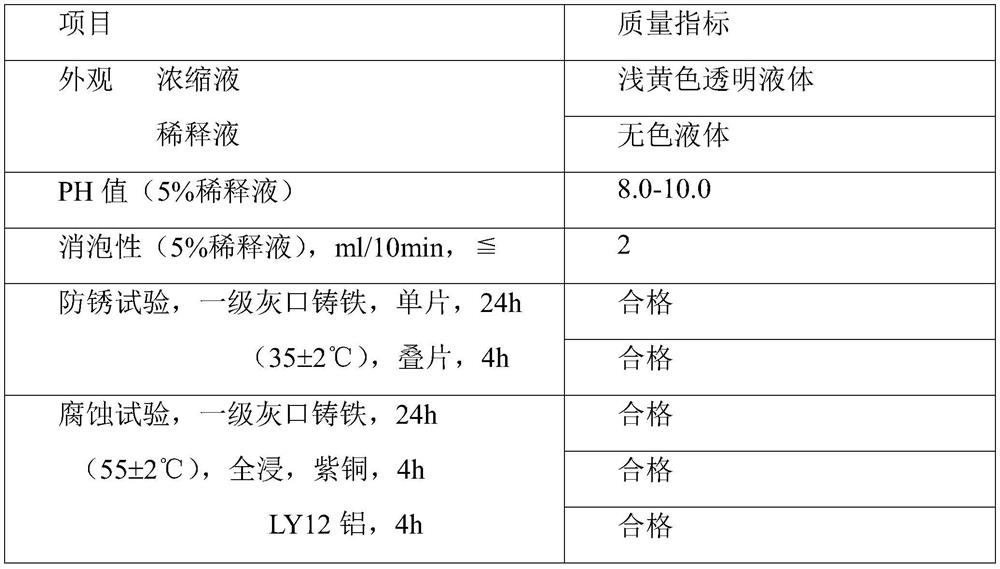

Examples

Embodiment 1

[0030] A special lubricating fluid for active metal processing, including the following components in proportion by weight:

[0031] 6 parts of alcohol amines, 3 parts of fatty acid polyethylene glycol ester, 2 parts of boric acid ester, 4 parts of carboxylic acid, 4 parts of polyether carboxylate, 3 parts of modified polyether, 0.7 part of complexing agent, 0.4 part of antioxidant 0.6 parts of anti-wear agent, 2 parts of magnesium slow-release agent, 0.08 parts of antifoaming agent, 32 parts of pure water.

Embodiment 2

[0033] A special lubricating fluid for active metal processing, including the following components in proportion by weight:

[0034] 10 parts of alcohol amines, 7 parts of fatty acid polyethylene glycol ester, 4 parts of boric acid ester, 5 parts of carboxylic acid, 6 parts of polyether carboxylate, 4 parts of modified polyether, 2 parts of complexing agent, 2 parts of antioxidant 1 part, anti-wear agent 1 part, magnesium slow-release agent 3 parts, defoamer 1 part, pure water 35 parts.

Embodiment 3

[0036] A special lubricating fluid for active metal processing, including the following components in proportion by weight:

[0037] 14 parts of alcohol amines, 11 parts of fatty acid polyethylene glycol ester, 7 parts of boric acid ester, 12 parts of carboxylic acid, 12 parts of polyether carboxylate, 7 parts of modified polyether, 4 parts of complexing agent, 4 parts of antioxidant 2 parts, anti-wear agent 2 parts, magnesium slow-release agent 5 parts, defoamer 1.5 parts, pure water 38 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com