Ironing device

An ironing device and ironing wheel technology, applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve problems such as low efficiency and restrictions on unmanned duty in factories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

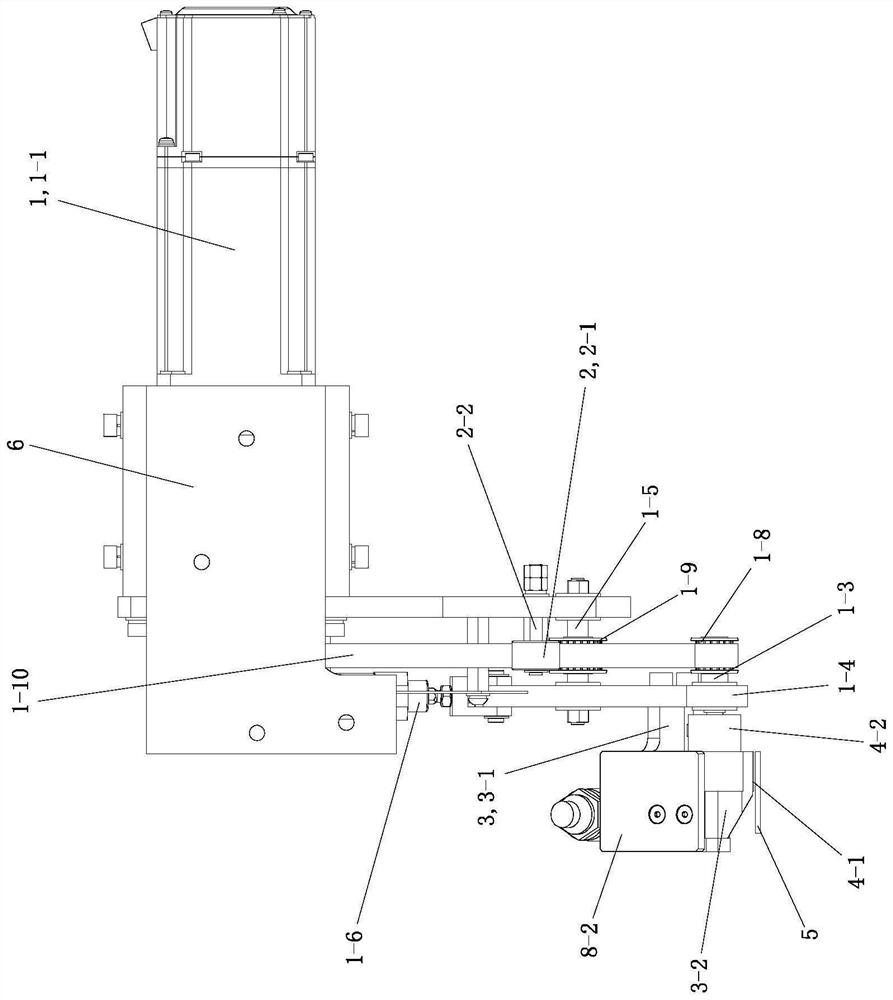

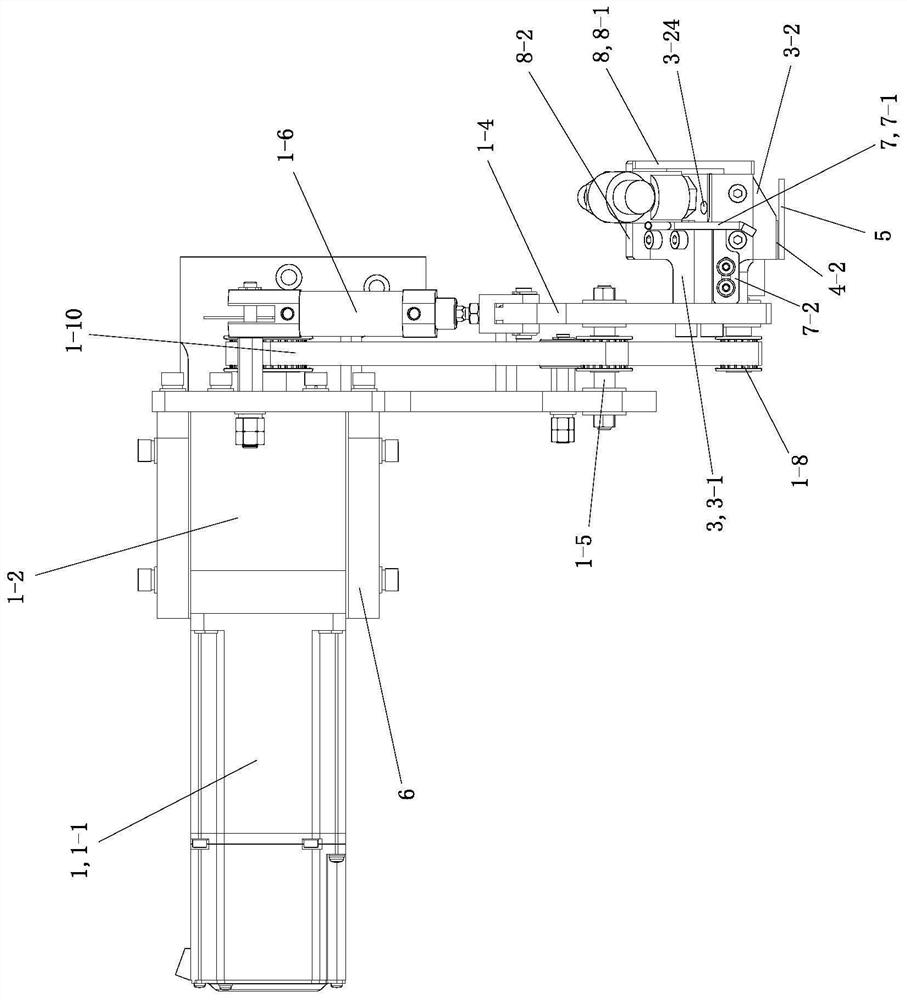

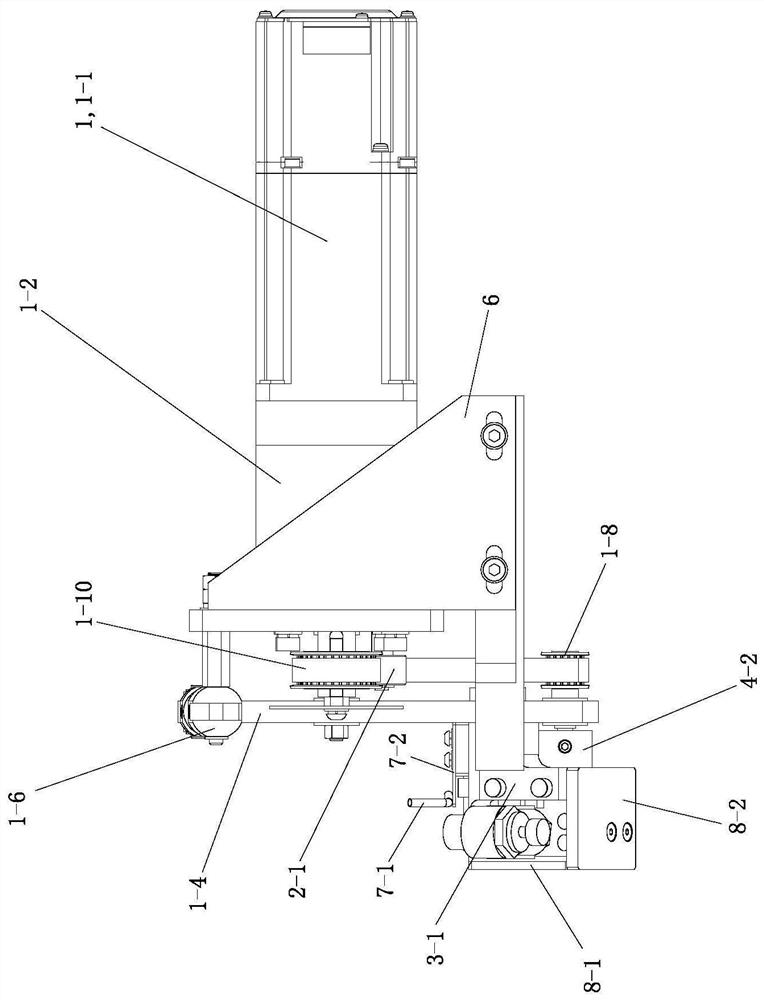

[0053] See Figure 1 to Figure 15 , The ironing device of the present invention includes a driving mechanism 1 , a tensioning mechanism 2 , a heating assembly 3 , an ironing wheel 4 , a backing plate 5 , a connecting seat 6 , a cooling assembly 7 and a protection assembly 8 .

[0054] See Figure 1 to Figure 10 , the drive mechanism 1 includes a drive motor 1-1, a reducer 1-2, a drive shaft 1-3, a swing arm 1-4, a swing shaft 1-5, a swing arm cylinder 1-6, and a first synchronous pulley 1-7 , the second synchronous pulley 1-8, the 3rd synchronous pulley 1-9 and synchronous belt 1-10.

[0055] The drive motor 1-1 is fixedly arranged on the reducer 1-2, and the motor shaft of the drive motor 1-1 is connected to the input end of the reducer 1-2 through transmission. The speed reducer 1-2 is fixedly arranged on the connection seat 6, and its output shaft stretches out to the left. The transmission of the first synchronous pulley 1-7 is fixedly arranged on the output shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com