Environment-friendly ozone microbubble enzyme desizing process for cotton fabric

A cotton fabric and micro-bubble technology, which is applied in textile industry wastewater treatment, enzyme/microbial biochemical treatment, water aeration, etc., can solve problems such as poor desizing effect, inability to treat wastewater, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] In the picture:

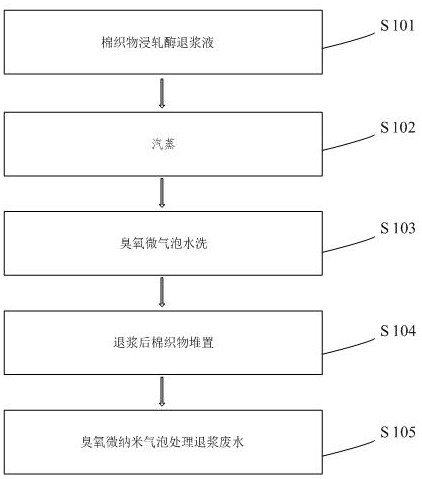

[0018] as attached figure 1 shown

[0019] A kind of ozone micro-bubble enzymatic desizing environmental protection technology for cotton fabric specifically comprises the following steps:

[0020] S101: Cotton fabric padding enzyme desizing solution (working solution temperature 50°C, rolling rate 100-110%), followed by desizing operation; enzyme working solution prescription: desizing enzyme (2000 activity units) 2 g / L, refining Enzyme (2000 activity units) 2 g / L, penetrant 3 g / L, chelating dispersant 3 g / L);

[0021] S102: Cotton fabric steaming process (working temperature is set to 98°C, working time is set to 1.0~1.5min);

[0022] S103: Ozone microbubble water washing (working temperature is set to 75°C, working time is set to 3~5min) is about 25% lower than conventional water washing temperature;

[0023] S104: After desizing, the cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com