Nafion/g-C3N4 composite film as well as preparation method and application thereof

A g-c3n4, composite membrane technology, applied in fuel cells, electrochemical generators, electrical components, etc., can solve problems such as inability to apply low temperature systems, low battery maximum power density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

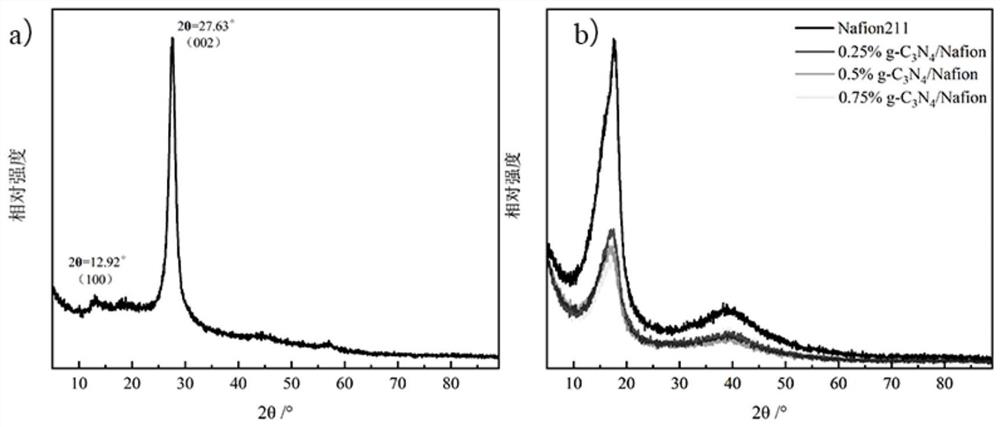

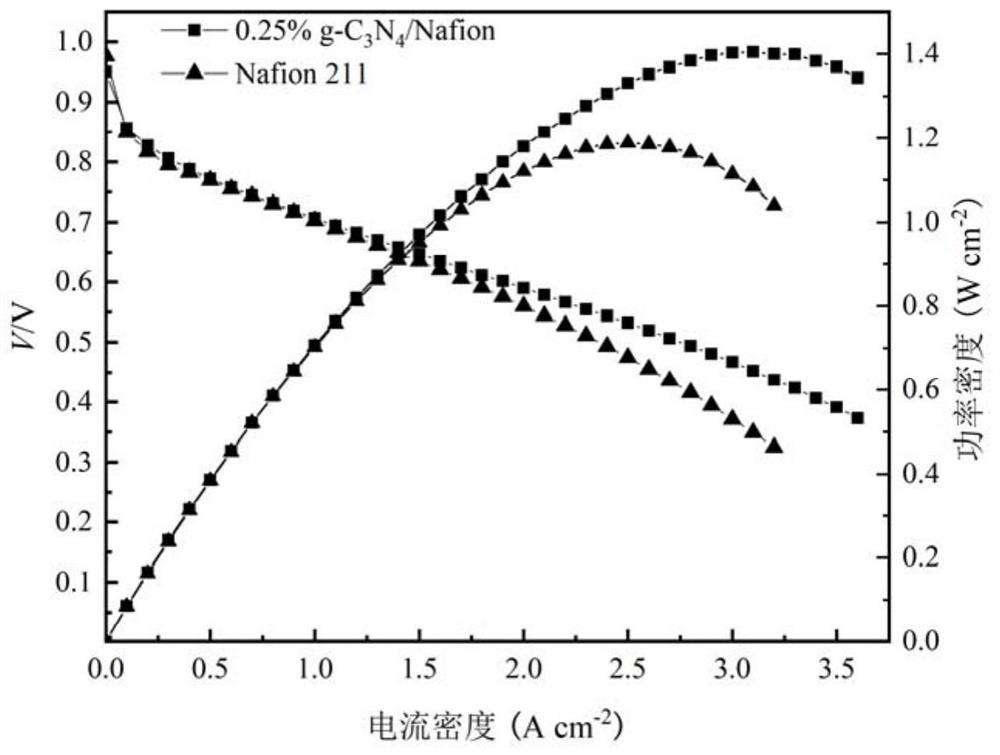

Embodiment 1

[0026] Get 100.1017g Nafion D520 solution and evaporate to dryness at 80 DEG C, time is 24h, obtain resin and redissolve with 95.0247gDMF again, obtain the Nafion solution that solute mass fraction is 5%, take 8.0124g above-mentioned solute mass fraction and be 5% Nafion solution, Add to it containing 1.0mg g-C 3 N 4 (obtained by calcining dicyandiamide as a precursor, g-C 3 N 4 dispersed in 2gDMF), stirred for 2h, ultrasonically dispersed for 4h, dried at 80°C for 24h to obtain a composite film, in which g-C 3 N 4 Relative to the mass ratio of Nafion resin is 0.25%, named 0.25% g-C 3 N 4 / Nafion. The prepared composite film was exposed to 0.5 M H at 80 °C 2 SO 4 Boil in the solution for 1 hour, then wash with 80°C deionized water until the washing solution is neutral, then dry in an oven at 80°C, and set aside.

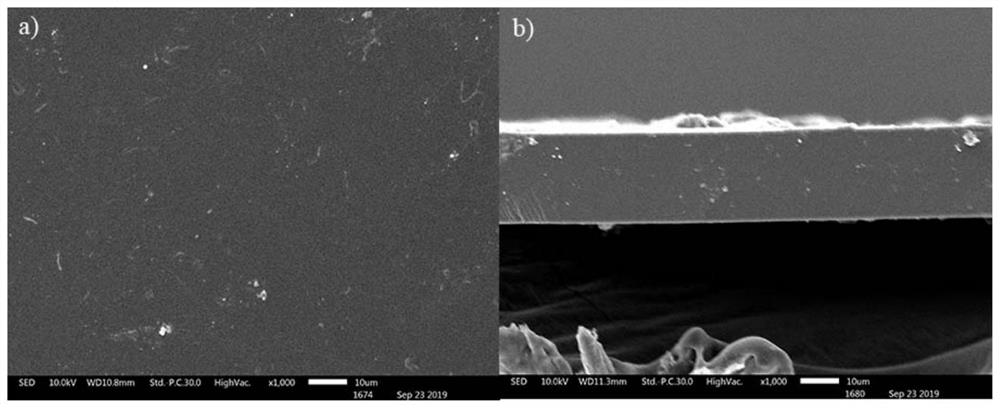

[0027] figure 1 a with figure 1 b are the surface and cross-sectional SEM images of the composite membrane obtained in Example 1, respectively. It can be...

Embodiment 2

[0031] Get 40.0047g Nafion D520 solution and evaporate to dryness at 90 DEG C, time is 28h, obtain resin and redissolve with 48.0522gDMAc again, obtain the Nafion solution that solute mass fraction is 4%, get 10.0017g above-mentioned solute mass fraction and be 4% Nafion solution, Add to it containing 2.0mg g-C 3 N 4 (obtained by calcination with melamine as precursor, g-C 3 N 4 dispersed in 2g DMF), stirred for 5h, ultrasonically dispersed for 10h, dried at 90°C for 16h to obtain a composite film, in which g-C 3 N 4 Relative to the mass ratio of Nafion resin is 0.5%, named 0.5% g-C 3 N 4 / Nafion. The prepared composite film was exposed to 0.5 M H at 80 °C 2 SO 4 Boil in the solution for 1 hour, then wash with 80°C deionized water until the washing solution is neutral, then dry in an oven at 80°C, and set aside.

Embodiment 3

[0033] Get 100.1044g Nafion D520 solution and evaporate to dryness at 90 DEG C, time is 20h, obtain resin and redissolve with 45.0247gNMP again, obtain the Nafion solution that solute mass fraction is 10%, get 4.0124g above-mentioned solute mass fraction and be 10% Nafion solution, Add 3.0mg g-C to it 3 N 4 (obtained by calcining dicyandiamide as a precursor, g-C 3 N 4 dispersed in 2gDMF), stirred for 10h, ultrasonically dispersed for 10h, dried at 90°C for 16h to obtain a composite film, in which g-C 3 N 4 Relative to the mass ratio of Nafion resin is 0.75%, named 0.75% g-C 3 N 4 / Nafion. The prepared composite film was exposed to 0.5 M H at 80 °C 2 SO 4 Boil in the solution for 1 hour, then wash with 80°C deionized water until the washing solution is neutral, then dry in an oven at 80°C, and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com