Quantum dot and preparation method and application thereof

A quantum dot and preparation process technology, applied in the field of quantum dots, can solve the problems of failing to meet commercial requirements and low external quantum efficiency, and achieve the effects of meeting commercial requirements, low injection barriers, and favorable electron injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing the above-mentioned quantum dots, comprising the steps of:

[0054] S1, preparing the kernel;

[0055] S2, mixing the inner core with the first zinc precursor, aliphatic amine, and solvent to form a first precursor solution, and then adding the first cadmium precursor and the first sulfur precursor to the first precursor solution at a uniform speed respectively or together to form the second precursor solution Two precursor solutions, the molar ratio of Cd element to S element in the second precursor solution is 0.15:1~0.4:1;

[0056] S3, reacting the second precursor solution at the first temperature to coat the surface of the inner core to form a shell layer to obtain quantum dots.

[0057] In step S1, the preparation process of the core includes: mixing the second zinc precursor, the first selenium precursor, the second cadmium precursor, and the solvent, and reacting at a second temperature to obtain a solu...

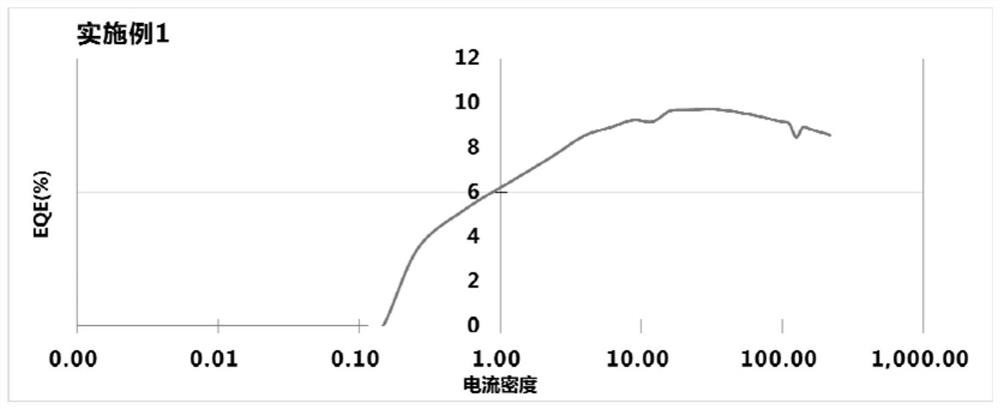

Embodiment 1

[0100] Take 2mmol basic zinc carbonate, 1.4mL oleic acid, and 12g octadecene, and raise the temperature to 280°C under the protection of nitrogen atmosphere to form a clear and transparent solution. Then inject 1.0mL 0.5mmol / mL Se-ODE suspension and 0.2mL 0.2mmol / mL cadmium oleate ODE precursor in sequence, raise the temperature to 300°C, add 0.5mL 2mmol / mL Se-TBP solution, and continue to heat up React at 310°C for 20 minutes. Purify to obtain 4.0nm CdZnSe quantum dots, which are dissolved in 10mL octadecene for later use.

[0101] Take 5.0 mL of the above-mentioned CdZnSe quantum dot solution, 10 mmol of zinc acetate, 25 mmol of oleic acid and 10 g of ODE, mix them, and raise the temperature to 150 ° C for 30 min under the protection of nitrogen. Then add 1mL oleylamine, raise the temperature to 300°C, and start to add Cd-ODE-S-TBP mixed solution (9mL 0.1mmol / mL cadmium oleate ODE solution mixed with 3mL 2mmol / mL S-TBP, Cd element and S element The molar ratio is 0.15:1), ...

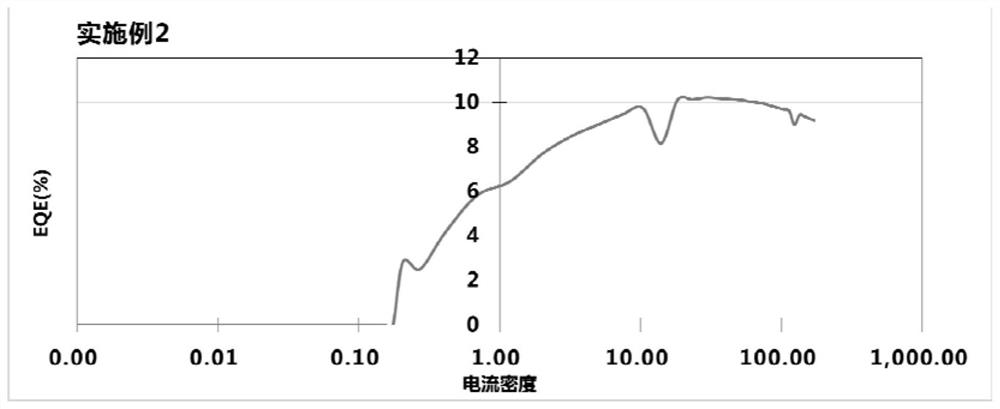

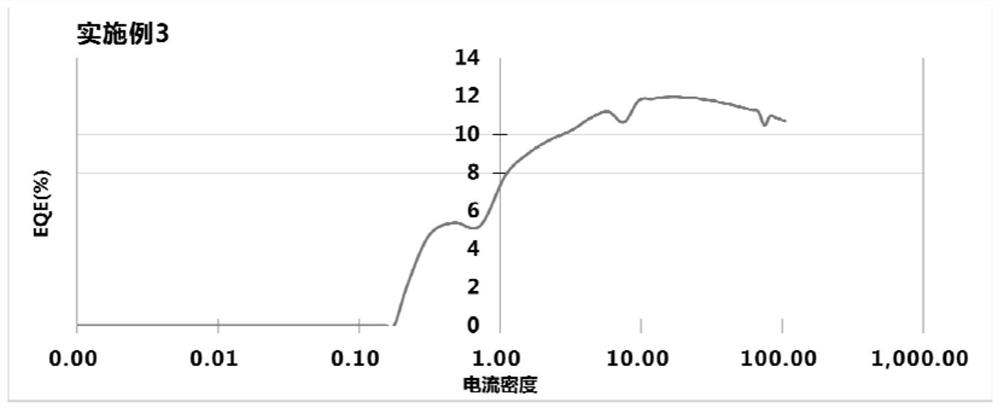

Embodiment 2

[0103] Take 2mmol basic zinc carbonate, 1.4mL oleic acid, and 12g octadecene, and raise the temperature to 280°C under the protection of nitrogen atmosphere to form a clear and transparent solution. Then inject 1.0mL of 0.5mmol / mL Se-ODE suspension and 0.4mL of 0.2mmol / mL cadmium oleate ODE precursor in sequence, raise the temperature to 300°C, add 0.5mL of 2mmol / mL Se-TBP solution, and continue to heat up React at 310°C for 60 minutes. Purify to obtain 5.5nm CdZnSe quantum dots, which are dissolved in 10mL octadecene for later use.

[0104] Take 5.0 mL of the above-mentioned CdZnSe quantum dot solution, 10 mmol of zinc acetate, 25 mmol of oleic acid and 10 g of ODE, mix them, and raise the temperature to 150 ° C for 30 min under the protection of nitrogen. Then add 1g of octadecylamine, raise the temperature to 300°C, start to add Cd-ODE-S-TBP mixed solution (8mL 0.1mmol / mL cadmium oleate ODE solution mixed with 2mL 2mmol / mL S-TBP, Cd element and S The molar ratio of the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com