Hollow rubber composite pad for lithium ion battery pack

A technology of lithium-ion battery packs and composite pads, which is applied in battery pack parts, rubber layered products, applications, etc., can solve the problems of battery pack assembly mismatch, hollow rubber pad deformation, low friction coefficient, etc., and achieve high friction force, improve the seismic capacity, the effect of large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

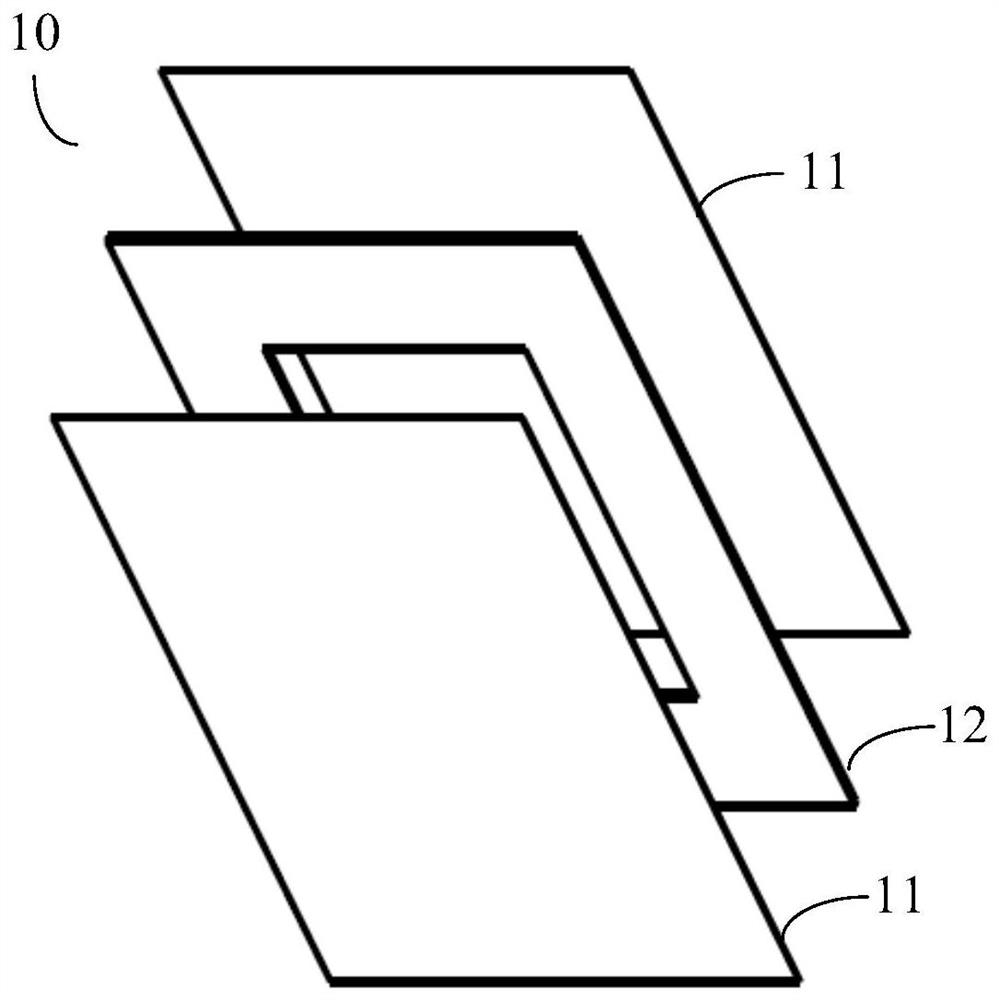

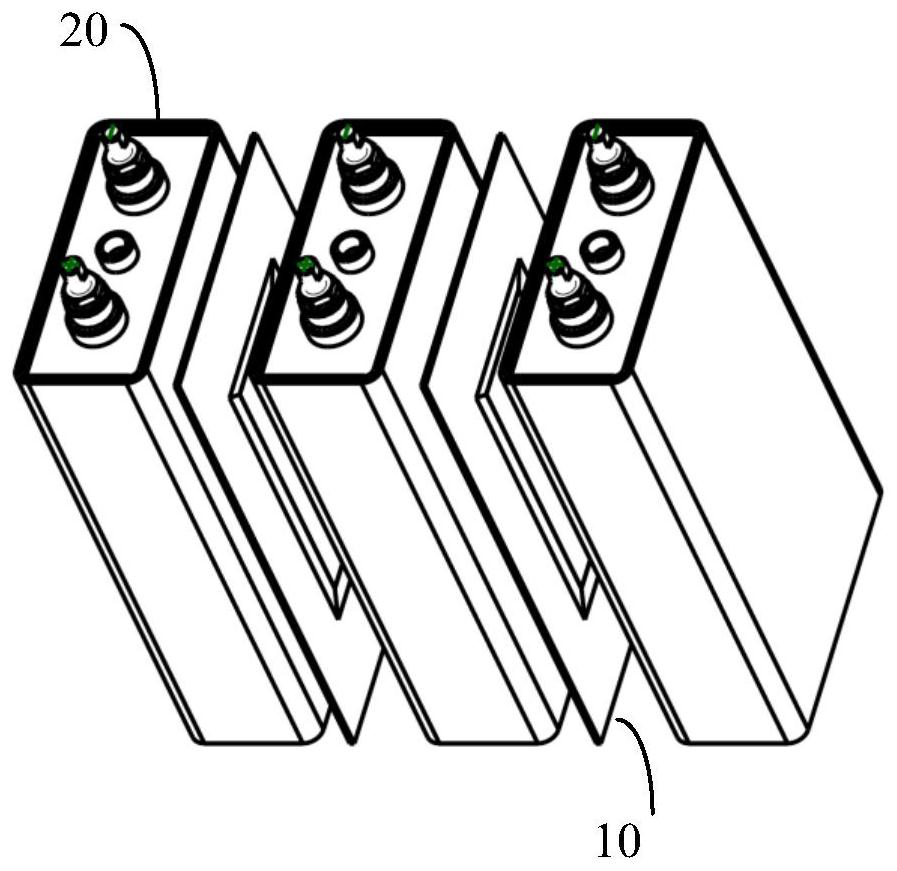

[0027] The invention provides a hollow rubber composite pad for a lithium-ion battery pack, which is characterized in that it includes: a polyimide film and a hollow rubber plate, wherein the polyimide film is two pieces, which are respectively pasted on the Both sides of the hollow rubber plate form the hollow rubber composite pad; the hollow rubber composite pad is placed between the adjacent surfaces of two adjacent single cells of the application battery pack.

[0028] According to an embodiment of the present invention, two pieces of polyimide membranes are respectively pasted on both sides of the hollow rubber plate by self-adhesive.

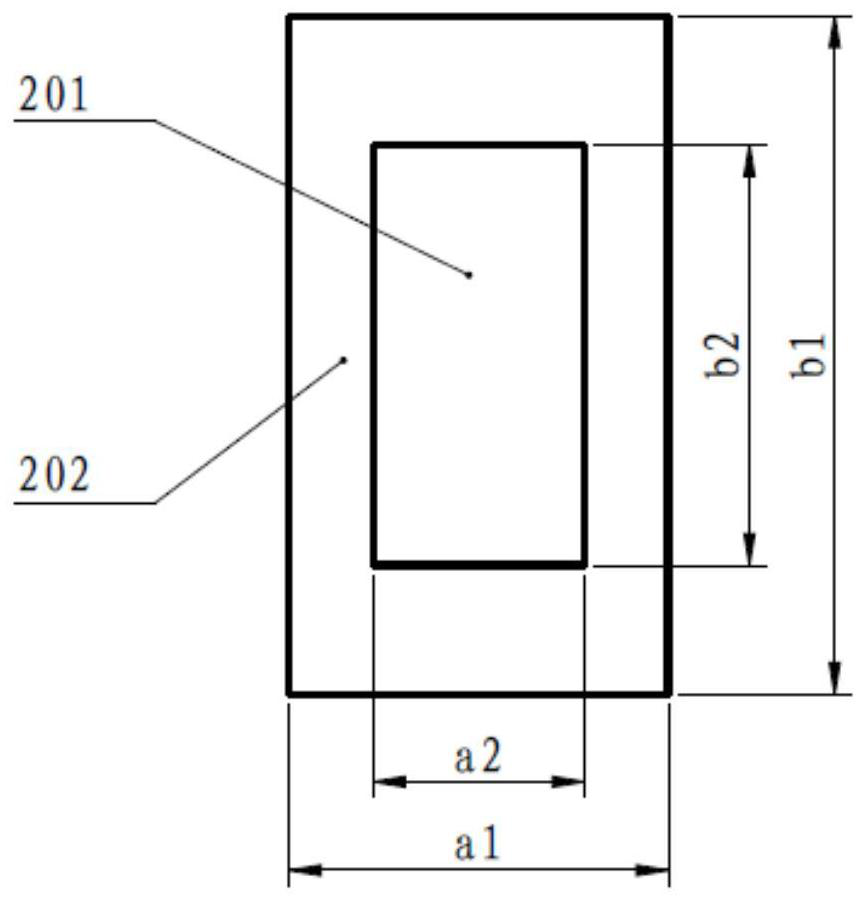

[0029] According to an embodiment of the present invention, the hollow rubber sheet is one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com