A high-strength plastic water-resistant gypsum decorative material and its preparation method

A decorative material and high-strength gypsum technology, applied in the field of gypsum decorative materials, can solve the problems of inconsistent shrinkage or expansion stress of gypsum decorative materials, and achieve the effects of reducing natural drying shrinkage, no powder falling, and small shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

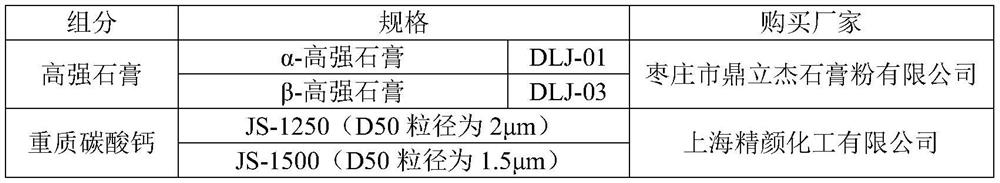

[0041] Embodiments 1-21 provide a high-strength plastic water-resistant gypsum decorative material, which is described below by taking Embodiment 1 as an example.

[0042] The high-strength plastic water-resistant gypsum decorative material provided by embodiment 1, its preparation steps are:

[0043] Mix 40g beta-high-strength gypsum, 10g ground calcium carbonate, 5g vitrified microbeads, 0.1g fumed silica, and 0.5g magnesium aluminum silicate, and stir to obtain a first mixture;

[0044] To the first mixture was added 0.5g of hydrophobic dispersible polymer powder, 0.05g of cream dispersant, 0.1g of hydroxypropyl methylcellulose ether, 0.05g of water repellent, 0.05g of water-retaining thickener and 0.05g g Gypsum retarder, mix evenly to obtain high-strength plastic water-resistant gypsum decorative material;

[0045] Wherein, the model of the β-high-strength gypsum is DLJ-03;

[0046] The model of the ground calcium carbonate is JS-1250 (D50 particle size is 2 μm);

[00...

Embodiment 2-5

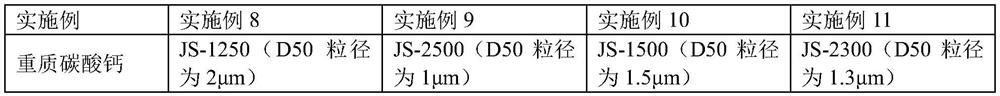

[0054] Examples 2-5 are the same as Example 1, except that the quality of the raw materials for preparing the high-strength plastic water-resistant gypsum decorative material is different, as shown in Table 2 for details.

[0055] Table 2

[0056] component Example 1 Example 2 Example 3 Example 4 Example 5 β-High Strength Gypsum 40g 60g 50g 50g 50g ground calcium carbonate 10g 30g 20g 20g 20g Vitrified beads 5g 15g 10g 10g 10g Fumed silica 0.1g 0.5g 0.3g 0.3g 0.3g Magnesium Aluminum Silicate 0.5g 1g 0.8g 0g 0.8g Hydrophobic dispersible polymer powder 0.5g 1.5g 1g 1g 1g Cream dispersant 0.05g 0.1g 0.08g 0.08g 0.08g Hydroxypropyl methylcellulose ether 0.1g 0.2g 0.15g 0.15g 0.1g water repellent 0.05g 0.1g 0.08g 0.08g 0.08g water retention thickener 0.05g 0.1g 0.08g 0.08g 0.05g Gypsum retarder 0.05g 0.13g 0.09g 0.09g 0.09g

Embodiment 6

[0057] Embodiment 6, with embodiment 3, differs only in that: the trade mark of described hydrophobic redispersible latex powder is by RE 5044N is replaced by 8031H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com