Patents

Literature

32results about How to "High thixotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machine-spraying-type plastering gypsum mortar and preparation technology thereof

ActiveCN104961423ASolve the problems that cannot meet the needs of mechanized constructionReduce dosageBond strengthMaterials science

The invention relates to machine-spraying-type plastering gypsum and a preparation technology thereof and belongs to the technical field of building materials. The machine-spraying-type plastering gypsum is characterized by being prepared from the following raw materials: 200-400 parts of gypsum, 10-60 parts of cement, 520-650 parts of fine aggregate, 80-160 parts of heavy calcium powder, 2-4 parts of redispersible emulsion powder, 2-4 parts of hydroxypropyl methyl cellulose ether, 0.15-0.25 part of an air entraining agent, 5-10 parts of expanded perlite, 0.3-0.8 part of a gypsum retarder and 200-300 parts of water. The machine-spraying-type plastering gypsum is applicable to being directly sprayed to a wall surface by adopting a mortar spraying machine, both time and labour are saved, construction efficiency can be improved, and cost is reduced; bonding performance with the wall surface is good, rebounce is not caused, anti-sagging performance is good, both bonding strength and compressive strength can meet requirements, and cracking of a wall body can be reduced; and usage amount of gypsum is low, and cost can be effectively reduced.

Owner:新疆荣高鸿骏新材料技术有限公司

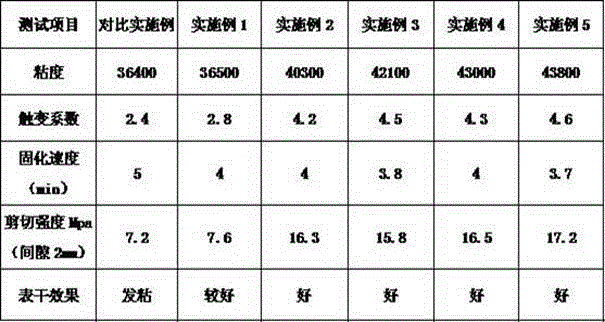

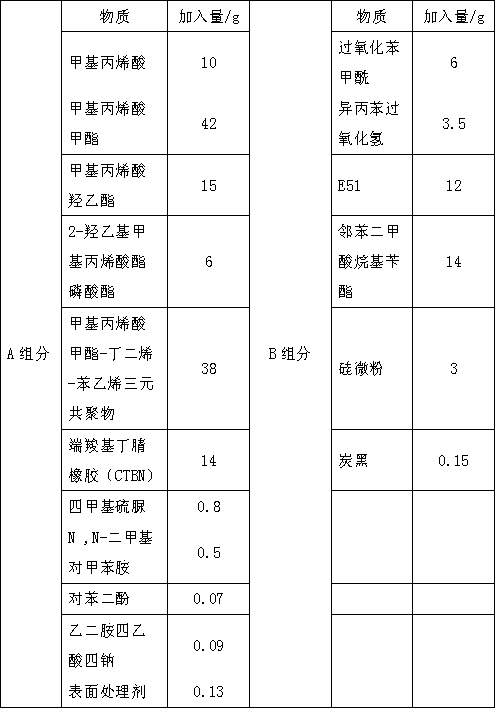

Double-component crylic acid adhesive and preparation method thereof

InactiveCN106634641ASolve the problem of sticky surface after curingHigh thixotropyNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyCross-link

The invention relates to a double-component crylic acid adhesive and a preparation method thereof. The double-component crylic acid adhesive consists of a component A and a component B in a volume ratio of 10:1, wherein the component A consists of the following raw materials in percentage by weight: 30-60% of an acrylic ester monomer, 10-30% of an active group toughening agent, 0.1-5% of a stabilizer, 0.1-5% of a reducing agent and 0.1-6% of an acceleration promoter; the component B consists of the following raw materials in percentage by weight: 10-40% of epoxy resin, 20-50% of a plasticizer, 10-30% of an oxidant and 0.1-10% of aids. The double-component crylic acid adhesive provided by the invention can be rapidly and completely cured, the cross-linking density and hardness can be improved, and the purposes of good surface dry and high adhesion strength can be achieved.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

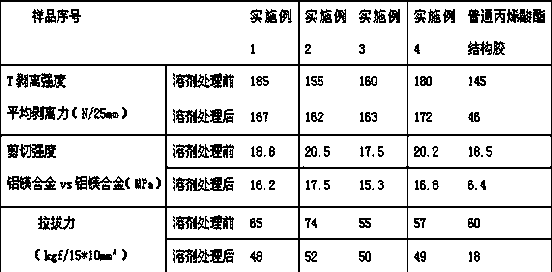

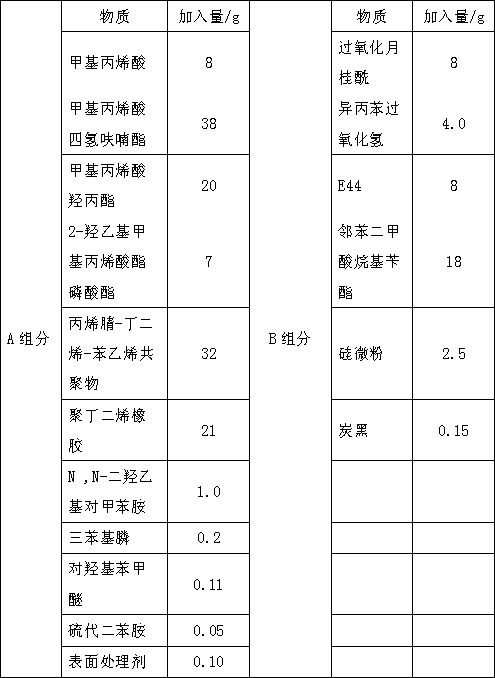

Acrylate structural adhesive being resistant against solvent scrubbing

InactiveCN107603497AGlue evenlyMix rubber evenlyNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive

The invention relates to an acrylate structural adhesive being resistant against solvent scrubbing, which includes a component A and a component B; the component A is composed of: an acrylate monomer,methacrylic acid, toughening rubber, toughening filler, an accelerant, a stabilizer and a coupling agent; the component B is composed of: an oxidizing agent, epoxy resin, a plasticizer, filler and pigments. The component A and the component B are uniformly stirred according to the volume ratio of 10:1 to produce the acrylate structural adhesive. The acrylate structural adhesive is resistant against solvent scrubbing, is high in thixotropy and is good in infiltrability on an adhesion interface. In addition, after solidification, an adhesive layer is good in toughness and is high in adhesion force between anodised alumina, Al / Mg alloy, an electrophoresis ED layer, ABS / PC and the like plastic alloy, etc.

Owner:YANTAI DARBOND TECH

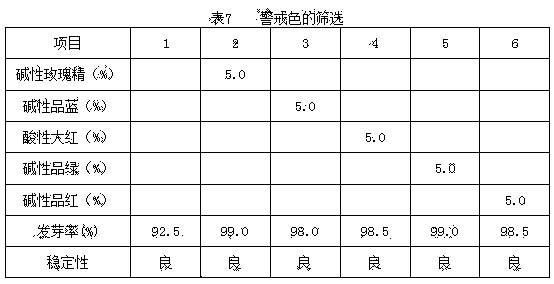

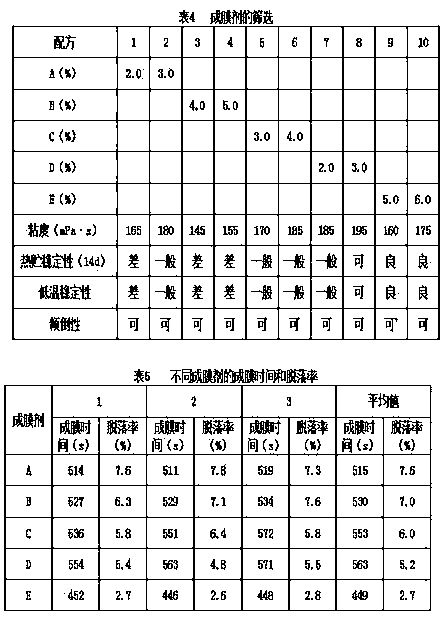

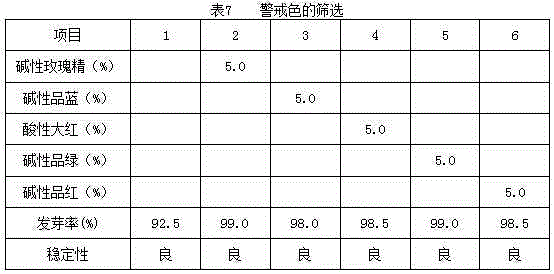

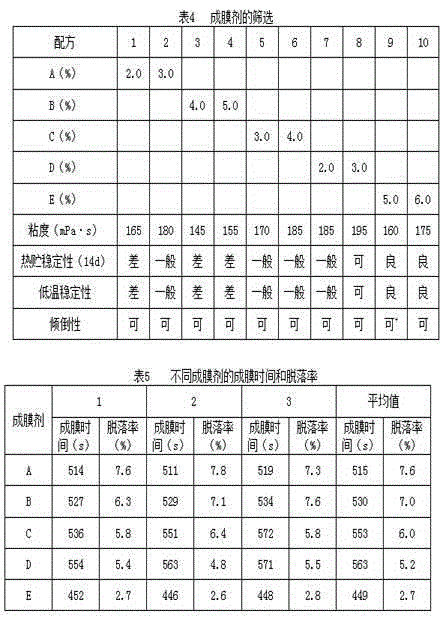

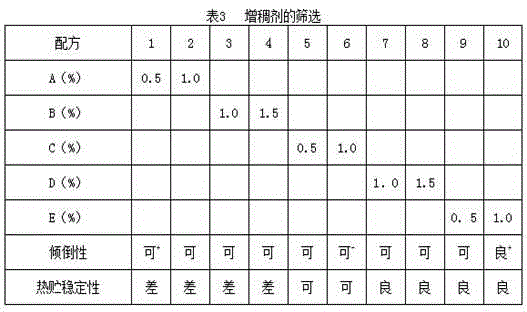

Suspended seed coating for preventing and curing corn smut and preparation method thereof

ActiveCN104255774AGood control effectNot easy to develop resistanceBiocideFungicidesBiotechnologySmut

The invention discloses a suspended seed coating for preventing and curing corn smut and a preparation method thereof. The suspended seed coating for preventing and curing corn smut is characterized by being prepared from the following raw materials in percentage by weight: 3.0-7.0% of imidacloprid, 7.0-12.0% of thiram, 0.2-0.6% of diniconazole, 1.5-2.5% of wetting dispersant, 0.5-1.5% of thickening agent, 2.0-6.0% of antifreezing agent, 0.1-0.3% of preservative, 2.0-6.0% of film-forming agent, 3.0-7.0% of warning colouration, 1.0-5.0% of microelements and the balance of water. The suspended seed coating disclosed by the invention is free of harmful effect on the emergence of seedlings and growth of corn, medicine is wrapped around seeds in a concentrated manner, and the medicine is slowly released. The average control effect for corn underground insects is 77.5%-83.5%, the control effect for head smut is 81.7%-88.4%, and the average growth rate is 16.4%-22.6%.

Owner:WUWEI CHUNFEI CROP SCI & TECH

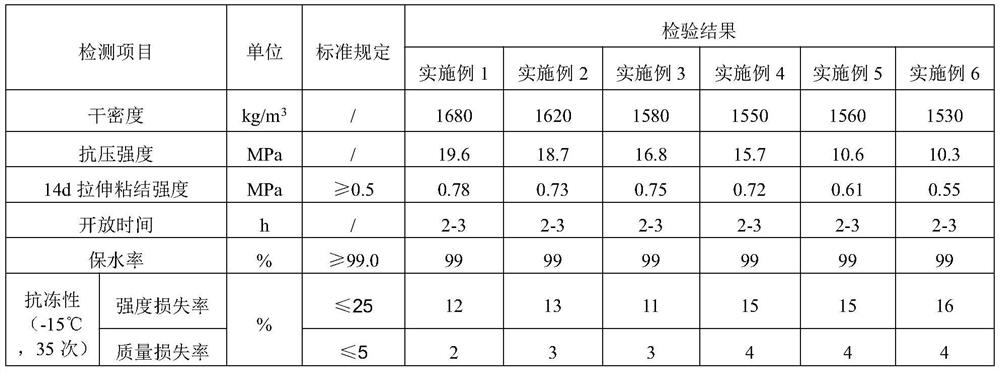

Low-temperature repairing material for high-speed rail base concrete in severe cold region and application of low-temperature repairing material

The invention belongs to the technical field of construction materials, and particularly relates to a low-temperature repairing material for a high-speed rail base concrete in a severe cold region and application of the concrete low-temperature repairing material. The low-temperature repairing material comprises the following components: 425 ordinary Portland cement, 425 sulphoaluminate cement, 725 sulphoaluminate cement, a waterproof admixture, rubber powder, an aggregate, a water reducer, a construction improver, a water-retaining agent, an early strength agent, a nano multifunctional water repellent agent, and PP (polypropylene) fiber. The low-temperature repairing material for the high-speed rail base concrete in the severe cold region, provided by the invention, has a repairing construction time meeting a skylight time requirement of a high-speed rail, has compression strength after completion of hydration matching with that of the base concrete, is high in tensile bond strength with the base concrete, is slightly expanded and strong in anti-freezing circulation capability at -40 DEG C, can avoid secondary detachment, and well meets requirements on the low-temperature repairing material for the high-speed rail base concrete in the severe cold region.

Owner:郑州筑邦建材有限公司 +1

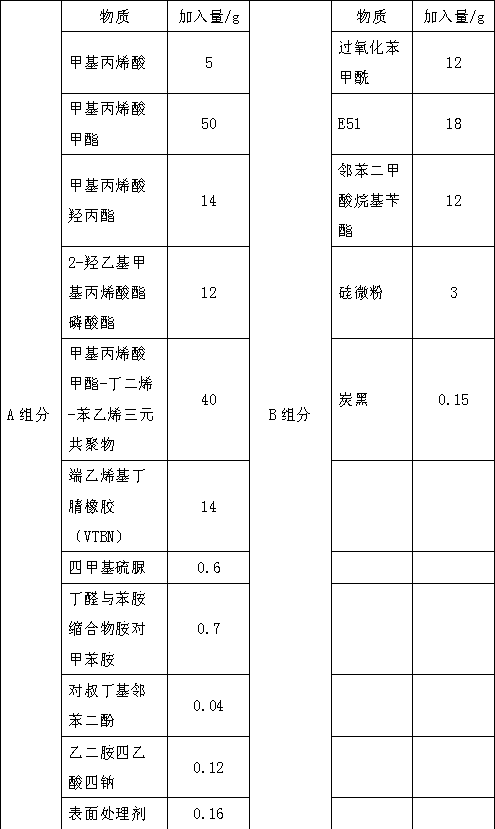

Acrylate structural glue suitable for zinc alloy bonding

ActiveCN108129993AGlue out smoothlyMix rubber evenlyNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveSurface finishingPlasticizer

The invention relates to acrylate structural glue suitable for zinc alloy bonding. The acrylate structural glue comprises a component A and a component B. The component A comprises methacrylic acid, an acrylic monomer, a toughening agent I, a toughening agent II, a reducing agent, a stabilizer and a surface treatment agent. The component B comprises an oxidant, epoxy resin, a plasticizer, a fillerand a pigment. The above components A and B are uniformly mixed according to a volume ratio of the component A to the component B of 10: 1 to form the acrylate structural glue. The acrylate structural glue has excellent adhesiveness to conventional materials such as an ABS plastic alloy, an electrophoretic ED layer and anodized aluminum and is especially suitable for bonding of new materials in the zinc alloy notebook bonding industry.

Owner:YANTAI DARBOND TECH

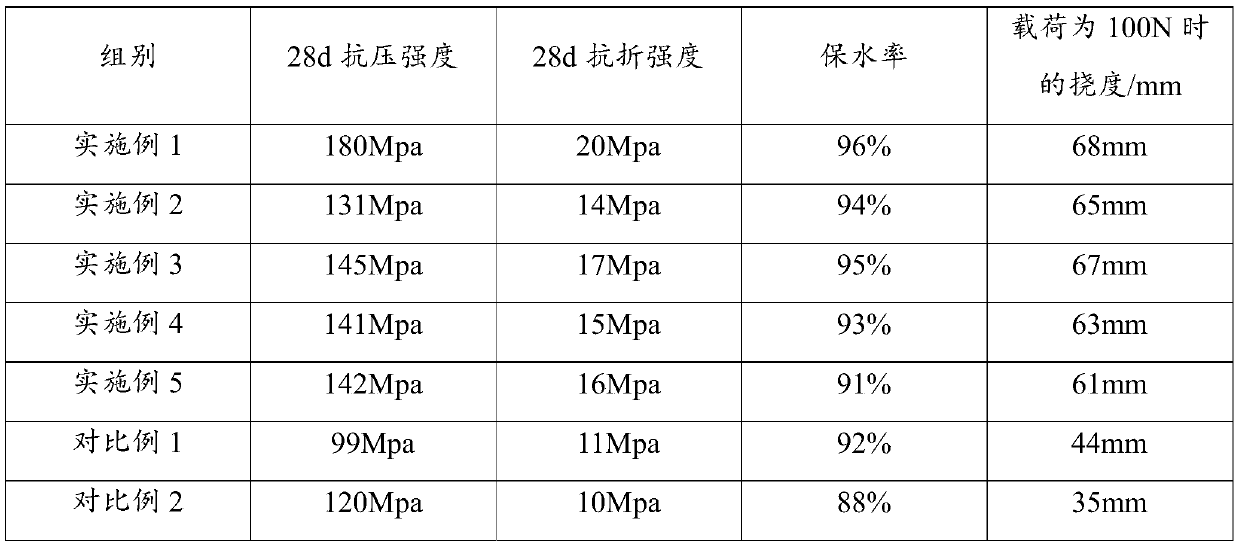

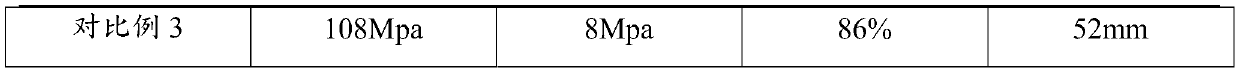

High-toughness and high-strength gypsum product and preparation method thereof

The invention discloses a high-toughness and high-strength gypsum product and a preparation method thereof. The high-toughness and high-strength gypsum product is prepared from the following components in parts by weight: 70-80 parts of gypsum powder, 15-20 parts of filler, 0.2-0.5 part of dispersing agent, 0.1-0.2 part of defoaming agent, 2-5 parts of dispersible latex powder, 5-10 parts of gypsum whisker and 1-5 parts of glass short fiber (or 0.1-0.5 part of chemical fiber short fiber). The high-toughness and high-strength gypsum product is high in strength: the 28d flexural strength is up to 20Mpa at most, and the 28d compressive strength is up to 180Mpa at most; and the surface hardness is up to 6H. The toughness is good: the maximum bending toughness is tested to be 68mm by adopting an MEW-40 wood universal testing machine. The technical problems that the traditional gypsum product is low in strength and poor in toughness are solved.

Owner:JINGMEN QIAN NIAN JIAN HEALTH CARE TECH

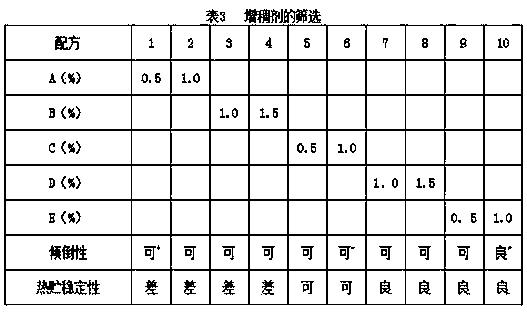

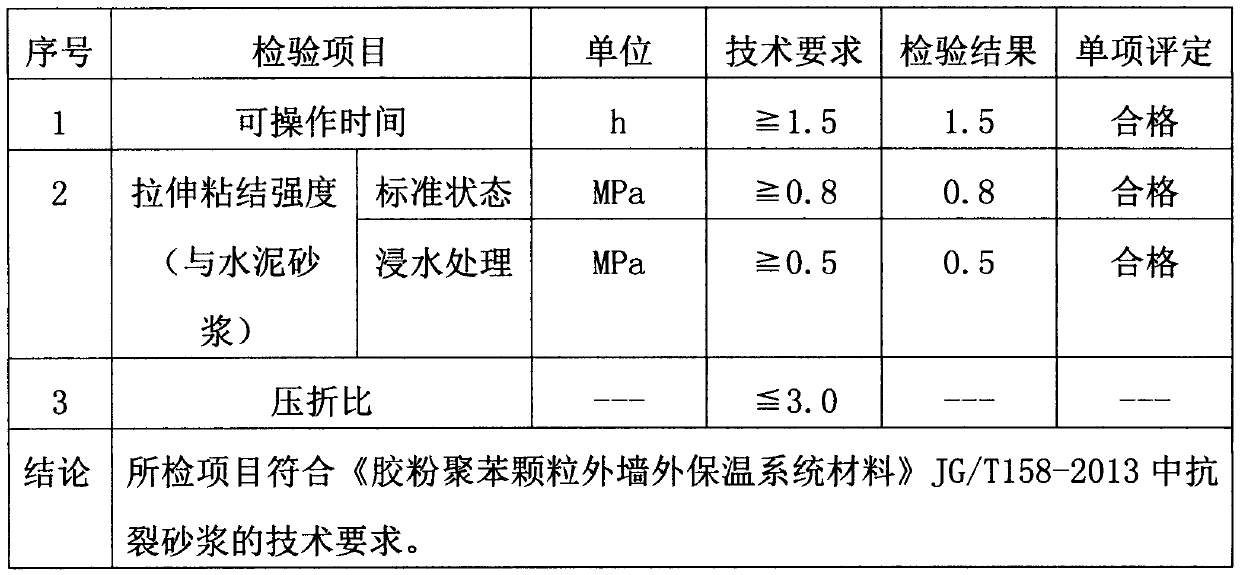

Anti-cracking mortar powder for thin plastering and leveling of inner walls and preparation method of anti-cracking mortar powder

The invention relates to anti-cracking mortar powder for thin plastering and leveling of inner walls and a preparation method of the anti-cracking mortar powder. The anti-cracking mortar powder for thin plastering and leveling of inner walls is prepared from the following raw materials: in parts by weight, 17-25 parts of a cementing material, 0-10 parts of active filler, 0-5 parts of inert filler,70-75 parts of aggregate, 0.1-0.2 part of a water-retaining thickener, 0-0.8 part of an adhesive, 0-0.5 part of a binder, 0.2-0.3 part of a water-conducting thickener, 0.05-0.15 part of crack-resistant fiber, 0-0.5 part of a slipping agent and 0-0.1 part of a thixotropic agent. The mortar powder has good water resistance, high strength, no easy cracking, no indoor environmental pollution and goodworkability.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP +1

One-component in-situ sprayed-up beaded mesh running track surface and preparation method therefor

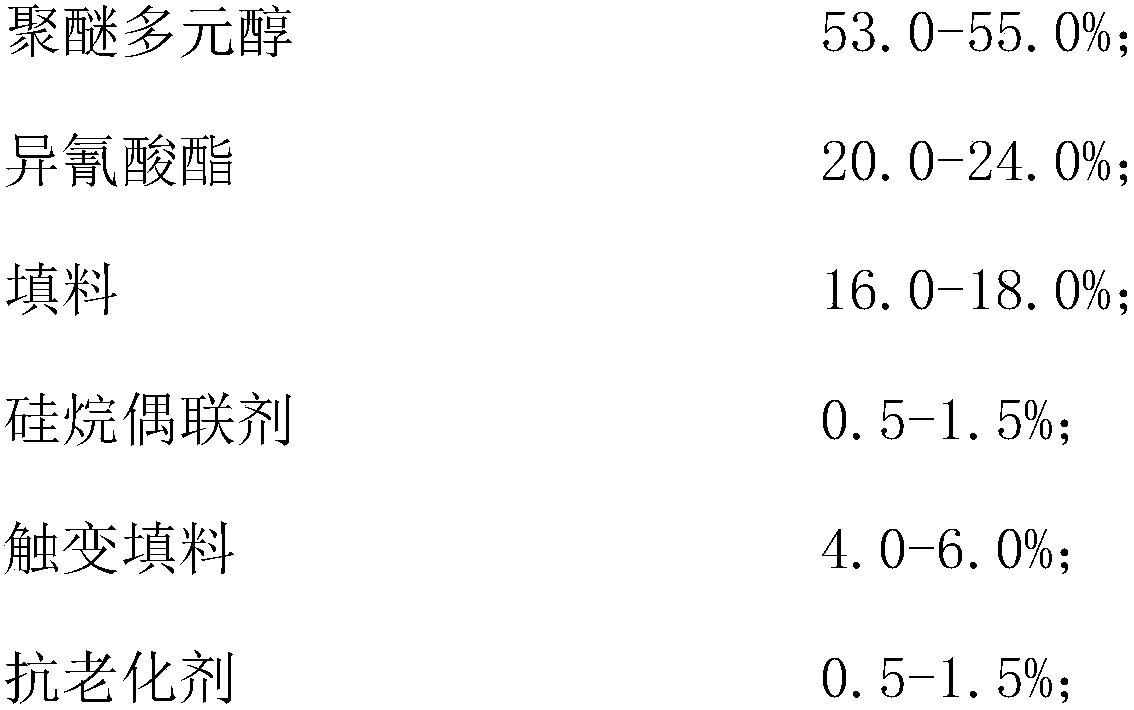

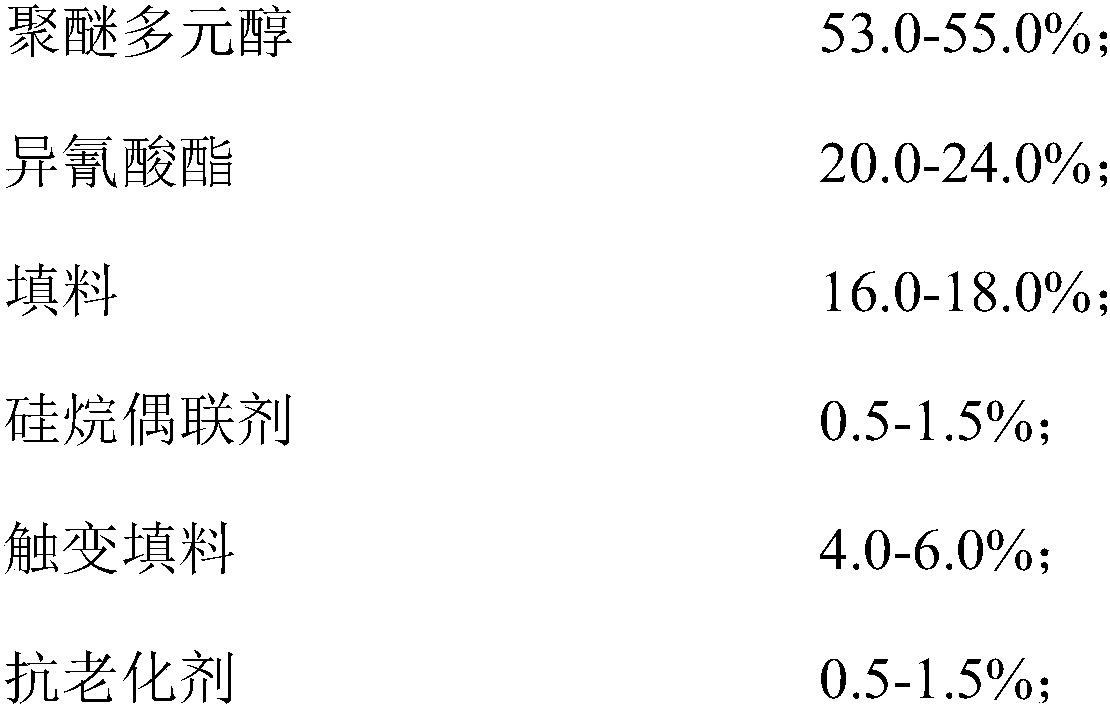

InactiveCN108064256AHigh thixotropyGood friction surfaceFireproof paintsGround pavingsSolventIsocyanate

The present invention discloses a one-component in-situ sprayed-up beaded mesh running track surface. The surface is a mixture of component A and component B; the component A comprises polyether glycol, isocyanate, a filler, a silane coupling agent, a thixotropic filler, and an anti-aging agent; the component B comprises a plasticizer, a filler, 9.0-11.0% of a toner, and a thixotropic filler. Thepresent invention also discloses a preparation method for the beaded mesh running track surface. The running track surface is one-component cured, solvent-free and all-plastic type without pellet.

Owner:JIANGMEN CHANGHE CHEM IND GRP

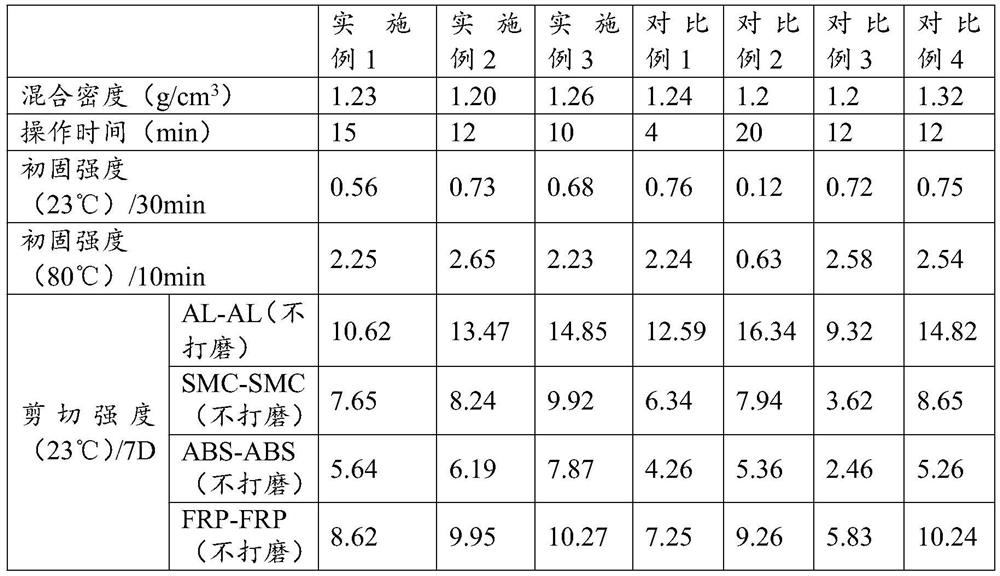

Quick-setting two-component polyurethane structural adhesive as well as preparation method and application thereof

ActiveCN111704885AReduce the temperatureReduced activityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to a quick-setting two-component polyurethane structural adhesive as well as a preparation method and application thereof. The component A in the double-component polyurethane structural adhesive is prepared from castor oil, autocatalytic polyol, tackifying resin, a coupling agent, a catalyst, filler, a molecular sieve and silicon dioxide, and the component B is prepared fromtoughened polyol, a plasticizer, isocyanate, glass beads, filler, a molecular sieve and silicon dioxide. The bi-component polyurethane structure not only has enough operation time, but also can be quickly cured, is high in bonding strength and universality, does not flow during vertical surface sizing, can meet the sizing process of various complex structures, and is very suitable for quick bonding and positioning of automotive upholstery.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +2

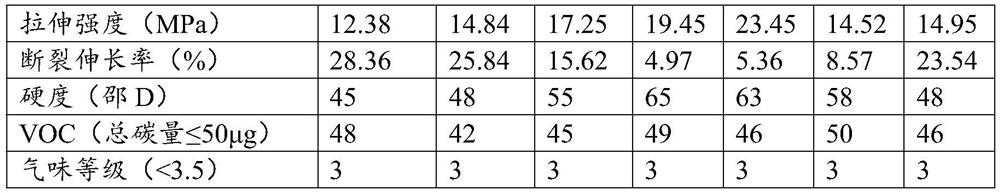

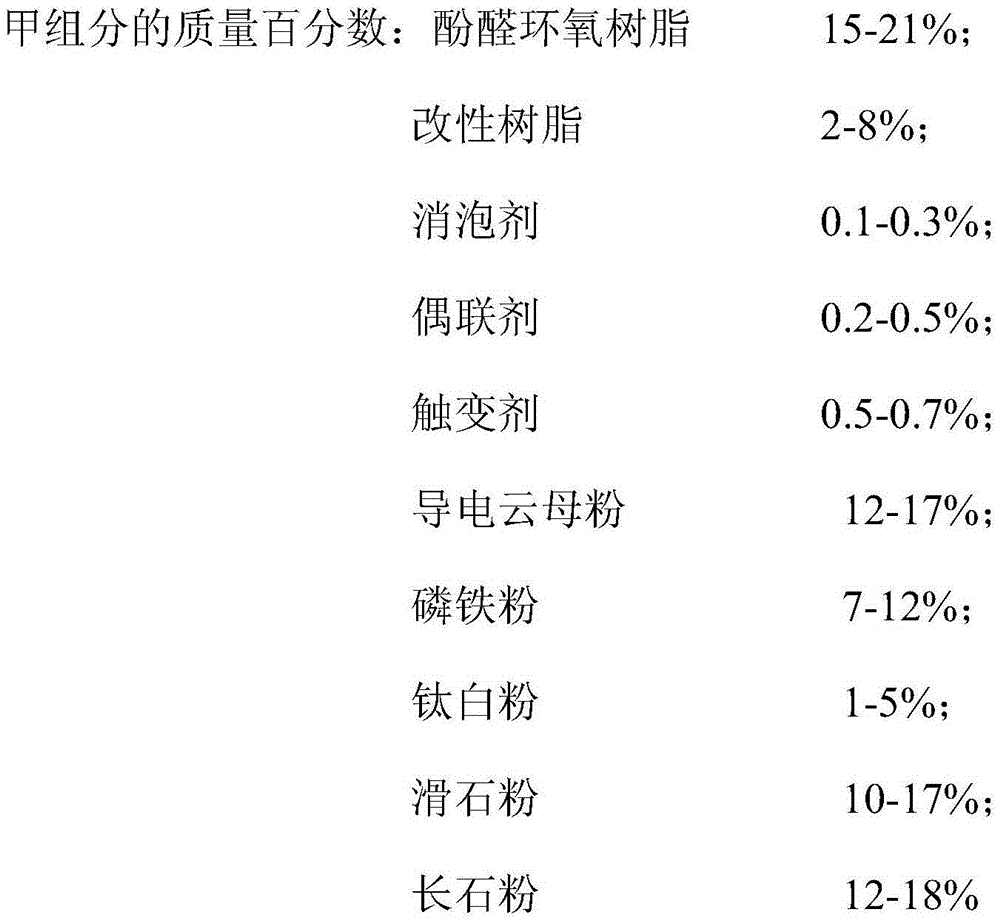

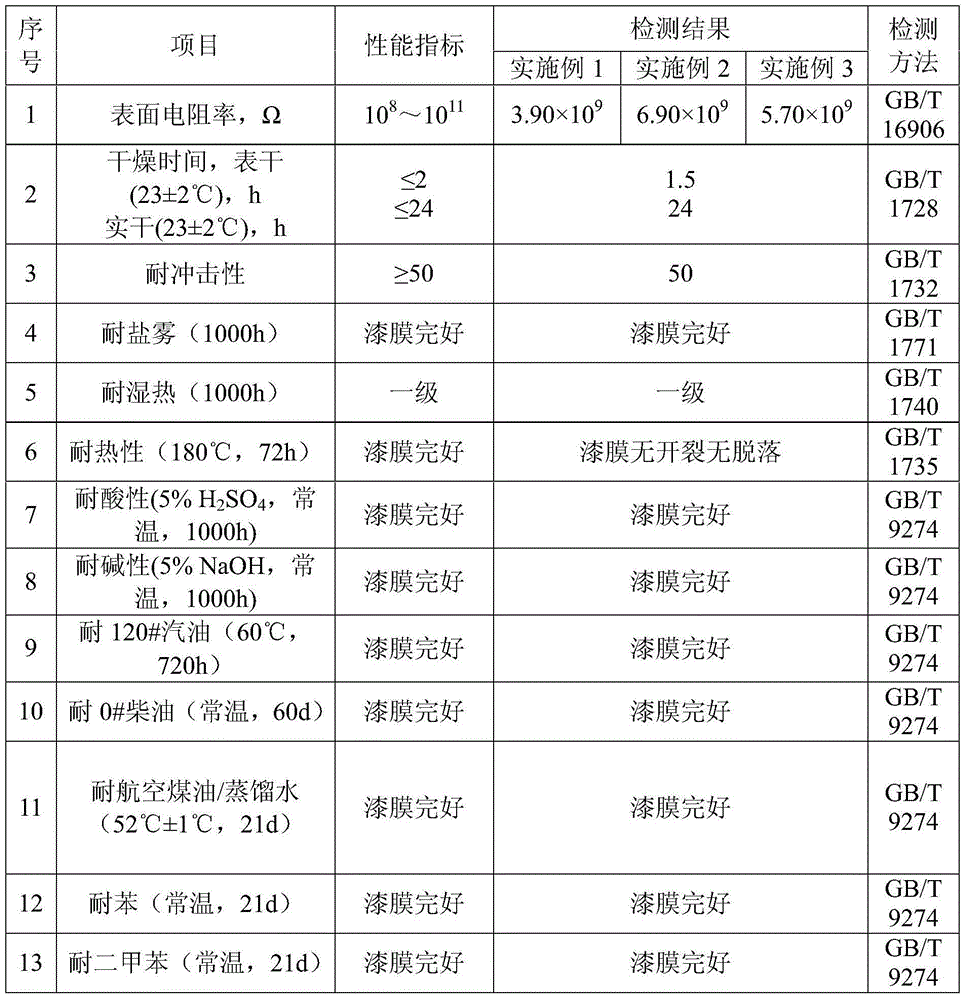

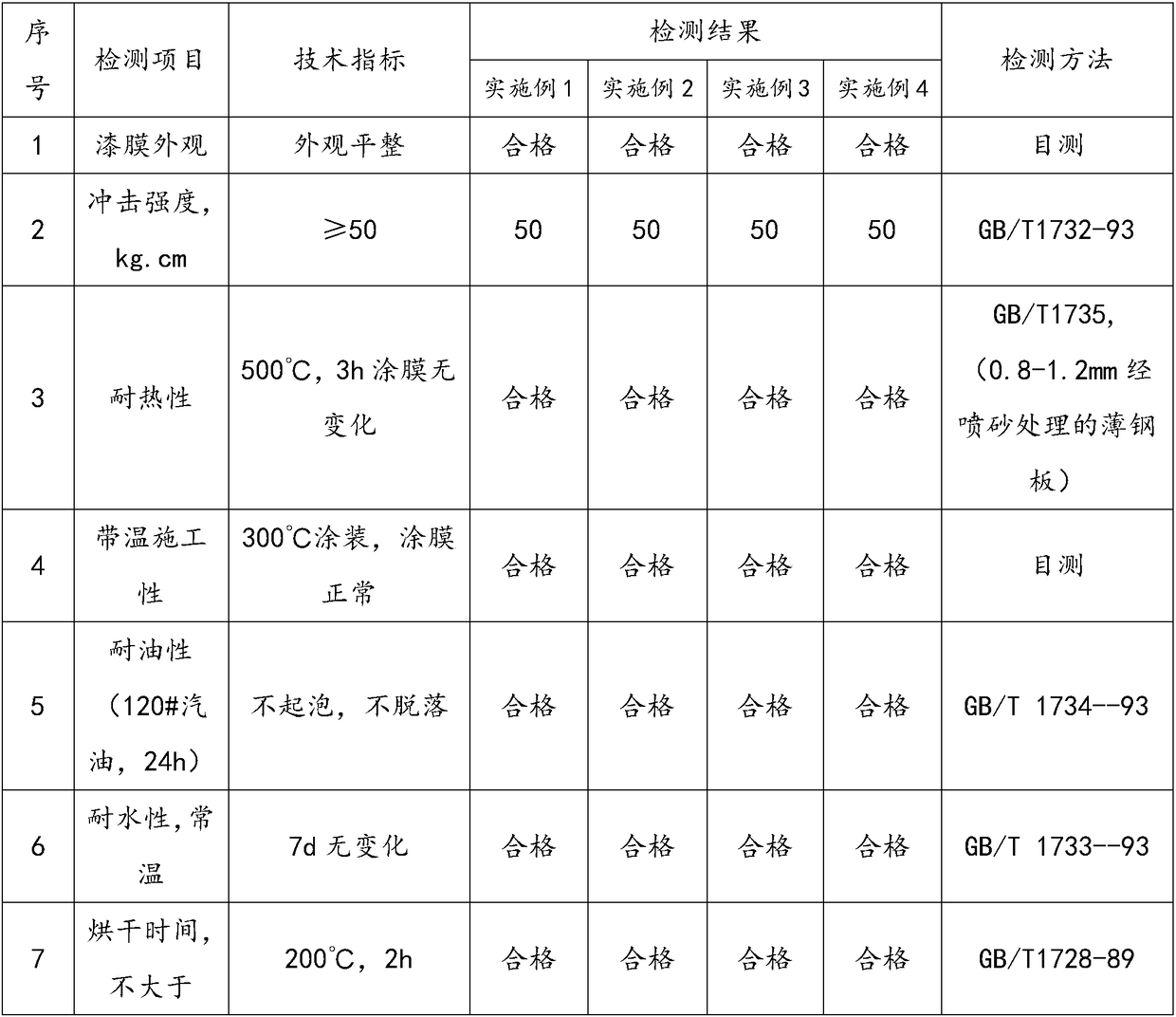

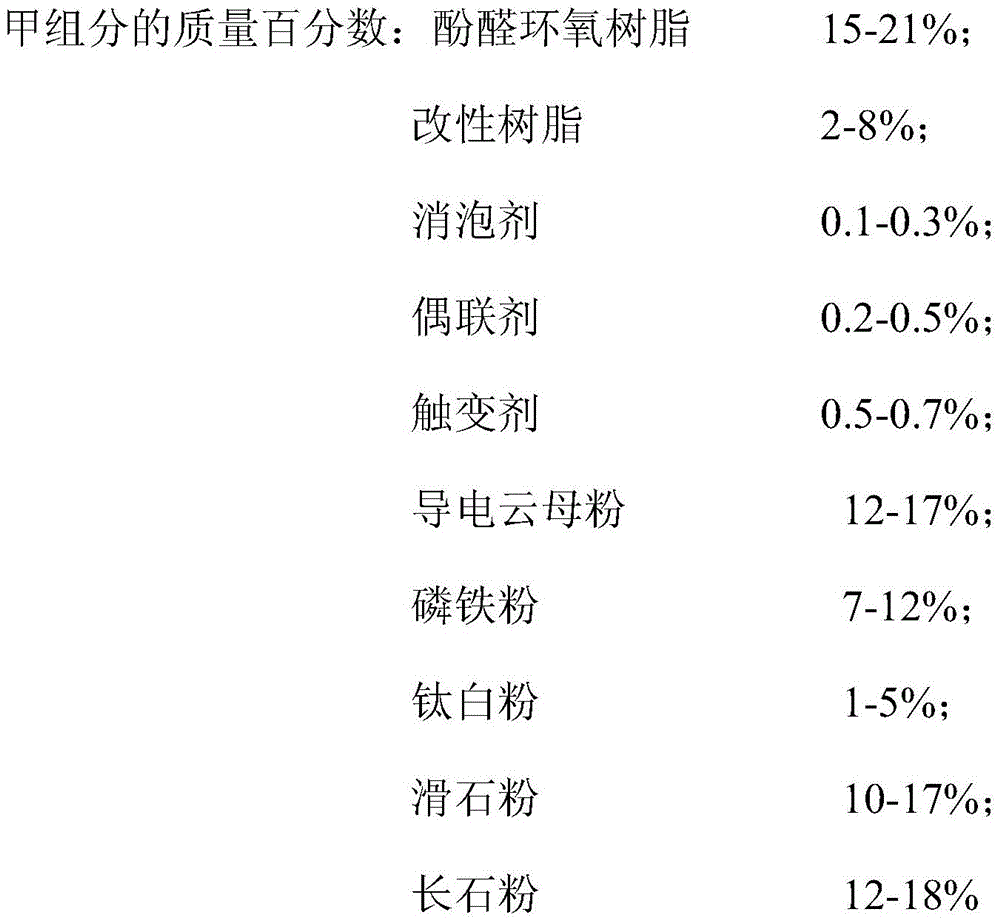

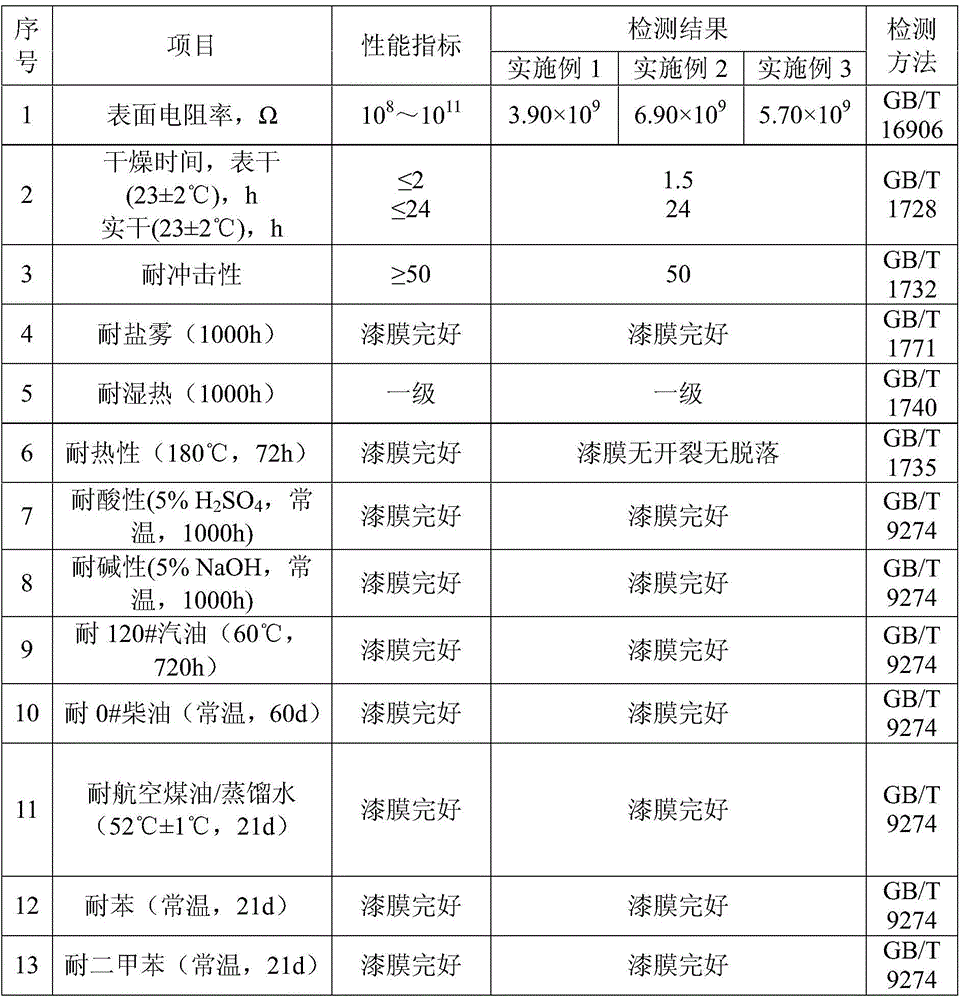

Heatproof oil-resistant phenolic epoxy static anticorrosive paint and preparation method thereof

ActiveCN104130673AImprove toleranceImprove heat resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyHeat resistance

The invention provides a heatproof oil-resistant phenolic epoxy static anticorrosive paint and a preparation method thereof, belonging to the field of paints. The paint comprises a component A and a component B. The component A comprises, by mass, 15 to 21% of a phenolic epoxy resin, 2 to 8% of a modified resin, 0.1 to 0.3% of an antifoaming agent, 0.2 to 0.5% of a coupling agent, 0.5 to 0.7% of a thixotropic agent, 12 to 17% of conductive mica powder, 7 to 12% of ferrophosphorous powder, 1 to 5% of titanium dioxide, 10 to 17% of talcum powder, 12 to 18% of feldspar powder and 15 to 20% of a solvent. The component B comprises, by mass, 65 to 75% of a curing agent and 25 to 35% of a solvent. The paint has effectively improved heat resistance and can resist a temperature as high as 200 DEG C; the paint has an excellent anticorrosive effect and excellent tolerance to acid, alkali, salt, oil and chemicals and is capable of enhancing an anti-rust effect and effectively reducing cost while providing conductive performance.

Owner:XIAMEN SUNRUI SHIP COATING

Acrylate adhesive for bonding bullet train roof reinforcing ribs

ActiveCN106590447AIncreased shear strengthHigh peel strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesDiamineChemistry

The invention discloses an acrylate adhesive for bonding bullet train roof reinforcing ribs, and relates to the field of acrylate structure adhesives. The acrylate adhesive comprises, by volume, 1 part of oxidizing agents and 7-15 parts of reducing agents. The oxidizing agent comprises, by weight, 30-50 parts of dibutyl phthalate, 1-5 parts of bisphenol-A-type epoxy resin, 15-20 parts of high-glue powder, 10-20 parts of benzoyl peroxide and 1-5 parts of castor oil. The reducing agents comprise, by weight, 20-54 parts of methyl methacrylate, 10-20 parts of impact modifiers, 10-15 parts of chlorosulfonated polyethylene, 1-3 parts of triethylene diamine, 0.5-1 part of paraffin, 1-5 parts of acrylic acid, 0.3-1 part of stabilizing agents and 1.2-1.6 parts of organic modified bentonite. The acrylate adhesive can be closely connected with bonding materials in high-frequency vibrating states and cannot peel when being used for a long time.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

Multipurpose convenient cement

InactiveCN104418545ANo pollution in the processAccurate and stable processing ratioCelluloseDry sand

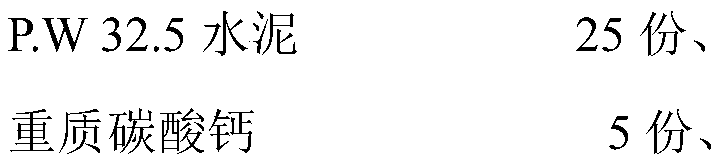

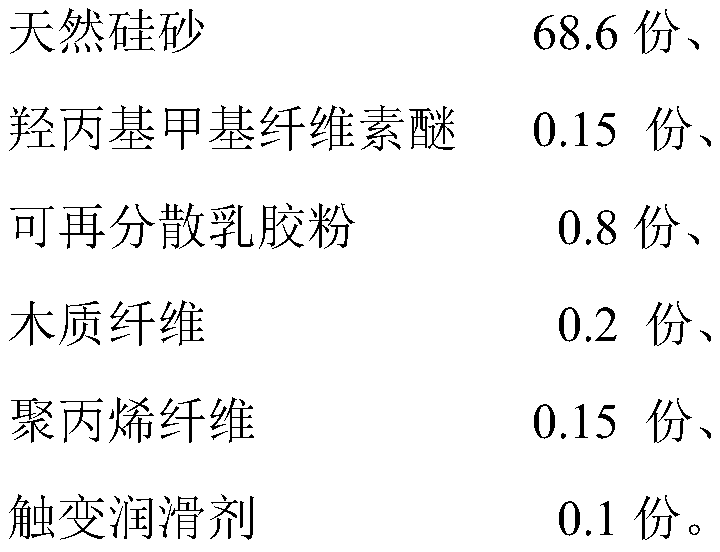

The invention relates to multipurpose convenient cement. The multipurpose convenient cement is composed of the following raw materials in parts by weight: 20-50 parts of cement, 41.9-66.65 parts of dry sand, 2-10 parts of calcium carbonate, 0.1-0.5 part of cellulose ether, 0.5-4.5 parts of redispersible latex powder, 0.05-0.1 part of an anti-skid auxiliary agent, and 0.1-0.5 part of starch ether. The product is prepared by screening natural sand, washing with water and sending to a baking rotary furnace to baking the natural sand to form dry sand, then pouring the above raw materials into an electric dry mixer according to the above ratios, stirring, after 10 min, conveying the uniformly-stirred raw materials into a material storage tank and packaging by a packager. The cement is environment-friendly, and has the fluidity, the volume density, the water retention property, the water-adsorption gas content, the plastic cracking property, the dry shrinkage, the compressive strength, the rupture strength, the adhesive strength, the flexibility, the impact resistance and the like all substantially better than those of common cement dry-mixed products.

Owner:JILIN DINGXI NEW BUILDING MATERIAL

Waterproof anti-crack mortar composition

The invention discloses a waterproof anti-crack mortar composition. The composition specifically comprises quartz sand, cement, light calcium carbonate, hydroxypropyl methyl cellulose, segmented fibers, starch ether and redispersible rubber powder. According to the mortar, the hydroxypropyl methyl cellulose, the anti-cracking fibers, the starch ether and the redispersible rubber powder are used asauxiliary materials for improving the comprehensive performance of the mortar, so that the waterproof anti-crack mortar composition has remarkable waterproof, anti-cracking and anti-falling effects,and the service life of the mortar is more than three times that of traditional mortar. By using the method, the construction amount is reduced, the construction efficiency is improved, the labor costis reduced, and the cost is greatly reduced. Meanwhile, the product is simple to use, can be used by adding a proper amount of water and then stirring uniformly, is convenient and quick, is an idealnovel building material, and is very worthy of vigorous popularization.

Owner:广西凯和建材有限责任公司

High-temperature trip temperature heat-resistant coating

InactiveCN108893053AImprove high temperature resistanceExtended service lifeAnti-corrosive paintsMetallic material coating processesZinc phosphateDiethylene glycol monobutyl ether

The invention discloses a high-temperature trip temperature heat-resistant coating which comprises a component A and a component B according to a mass ratio of 2:1, wherein the component A contains the following components in parts by weight: 15-30 parts of floating aluminum paste, 5-15 parts of barium sulfate, 5-10 parts of mica powder, 3-8 parts of zinc phosphate, 3-8 parts of aluminium triphosphate, 0.5-1 part of an anti-settling agent, 0.5-1 part of a thixotropic agent, 40-60 parts of a modified silicone polymer, 8-15 parts of diethylene glycol monobutyl ether and 0.2-0.5 part of an antifoaming agent; and the component B contains the following components in parts by weight: 2-3 parts of dioctyl phthalate and 2-3 parts of diethylene glycol monobutyl ether. The coating prepared by the formula disclosed by the invention is capable of performing construction in an environment of 300 DEG C or below, so that some production equipment which needs to be subjected to coating maintenance andhas high temperature can be directly maintained during production, and maintenance can be performed without shutdown and suspend production.

Owner:郑州朗纽防护材料有限公司

Special ultrathin-layer masonry mortar for sintered building blocks made of regenerated fine powder containing red bricks

ActiveCN112592131AImprove resource utilizationSolve the problem of comprehensive utilizationSolid waste managementCelluloseFiber

The invention aims to provide special ultrathin-layer masonry mortar for sintered building blocks made of regenerated fine powder containing red bricks. The special ultrathin-layer masonry mortar comprises the following components in parts by weight: 250-430 parts of cement, 195-375 parts of regenerated fine powder containing red bricks, 300-525 parts of fine sand, 6-10 parts of redispersible latex powder, 1.5-2 parts of hydroxypropyl methyl cellulose ether, 0.2-1.05 parts of water reducing agent and 0.3-0.5 part of wood fiber. According to the ultrathin-layer masonry mortar, all components utilize red brick-containing recycled fine powder, sorting and powder removal are not needed in the processing process of red brick-containing construction waste, the production process is low-carbon and environment-friendly, the cost is low, and the utilization problem of the sand powder mixture which is most difficult to utilize in the construction waste recycling process is successfully solved. The regenerated fine powder is adopted to partially replace natural fine sand, the mortar joint thickness of the obtained ultrathin-layer masonry mortar is not larger than 2 mm, and the ultrathin-layermasonry mortar has the advantages of being high in activity, high in water-retaining property, good in construction performance, capable of insulating heat and saving energy, environmentally friendlyand the like.

Owner:XUCHANG JINKE RESOURCE RECYCLING CO LTD

A heat-resistant and oil-resistant phenolic epoxy antistatic conductive anticorrosion coating and preparation method thereof

ActiveCN104130673BImprove toleranceImprove heat resistanceAnti-corrosive paintsEpoxy resin coatingsTO-18Epoxy

Owner:XIAMEN SUNRUI SHIP COATING

A kind of suspension seed coating agent for preventing and treating corn smut and preparation method thereof

ActiveCN104255774BGood control effectNot easy to develop resistanceBiocideFungicidesBiotechnologySmut

The invention discloses a suspended seed coating for preventing and curing corn smut and a preparation method thereof. The suspended seed coating for preventing and curing corn smut is characterized by being prepared from the following raw materials in percentage by weight: 3.0-7.0% of imidacloprid, 7.0-12.0% of thiram, 0.2-0.6% of diniconazole, 1.5-2.5% of wetting dispersant, 0.5-1.5% of thickening agent, 2.0-6.0% of antifreezing agent, 0.1-0.3% of preservative, 2.0-6.0% of film-forming agent, 3.0-7.0% of warning colouration, 1.0-5.0% of microelements and the balance of water. The suspended seed coating disclosed by the invention is free of harmful effect on the emergence of seedlings and growth of corn, medicine is wrapped around seeds in a concentrated manner, and the medicine is slowly released. The average control effect for corn underground insects is 77.5%-83.5%, the control effect for head smut is 81.7%-88.4%, and the average growth rate is 16.4%-22.6%.

Owner:WUWEI CHUNFEI CROP SCI & TECH

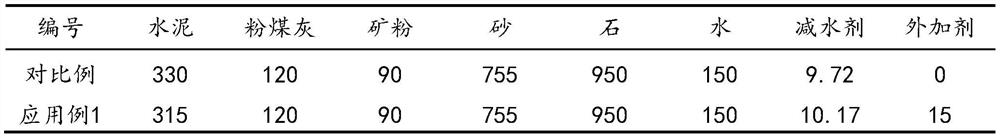

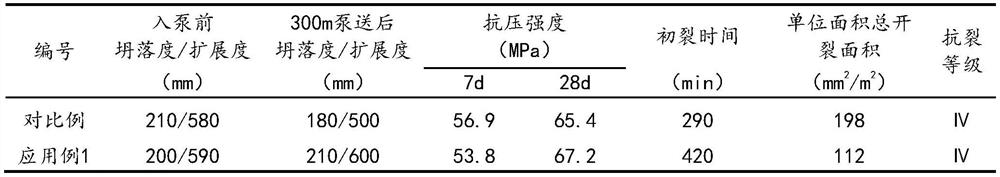

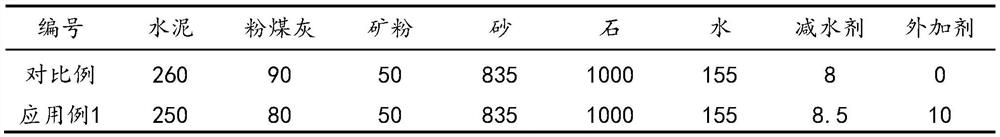

An admixture for improving crack resistance and thixotropic performance of super high-rise pumped concrete

The invention belongs to the field of building materials, and in particular relates to an admixture for improving the anti-cracking and thixotropic properties of super-high-rise pumped concrete. The admixture is composed of silica fume, fly ash microbeads, superfine limestone powder, modified montmorillonite and microcrystalline cellulose modified superabsorbent resin fiber. Based on the theory of close packing of particles, the invention uses silica fume, fly ash microbeads and ultra-fine limestone powder to optimize the particle composition of super-high-rise pumped concrete cementitious materials, and utilizes the strong water absorption and slow penetration of modified montmorillonite to release water Function and microcrystalline cellulose modified superabsorbent resin fiber surface hydrophilic and super-adsorption characteristics, improve the thixotropic performance and crack resistance of concrete, reduce the risk of concrete pumping pipe plugging and construction difficulty.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Adhesive special for steel-ceramic composite wear-resisting roller

InactiveCN105670544AHigh strengthImprove impact resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyCeramic composite

The invention relates to a special adhesive for steel-porcelain composite wear-resistant rollers, which is made of the following materials by weight percentage: 20-30% of epoxy resin, 5-10% of toughening agent, 2-4% of curing agent, and 5% of quartz sand -20%, silica powder 25-45%, dispersant 0-1%, coupling agent 0-2%, thixotropic agent 0-3%, reactive diluent 2-6%. The special adhesive for composite wear-resistant rollers made of the above materials has high strength, strong adhesion, good impact resistance, anti-sagging, high thixotropy, and can effectively combine steel rollers and ceramic strips to form a permanent one. The structure not only makes the roller more flexible and reliable, but also has a service life more than three times that of ordinary ceramic rollers.

Owner:FOSHAN SANSHUI SENO BUILDING MATERIAL

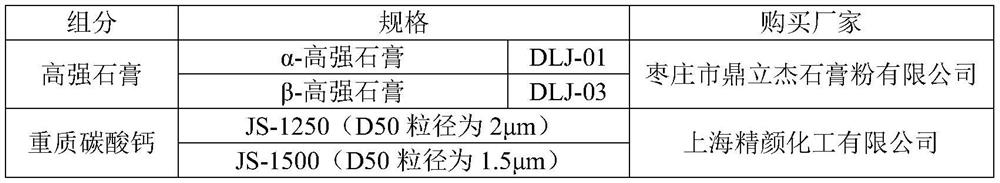

A high-strength plastic water-resistant gypsum decorative material and its preparation method

The application relates to gypsum decorative materials, in particular to a high-strength plastic water-resistant gypsum decorative material and a preparation method thereof. In parts by weight, the raw materials for preparing the high-strength plastic water-resistant gypsum decorative material include: 40-60 parts of high-strength gypsum, 10-30 parts of heavy calcium carbonate, 5-15 parts of vitrified microbeads, 0.05-0.1 part of water-repellent agent, Water-retaining thickener 0.05-0.1 part, hydrophobic redispersible latex powder 0.5-1.5 part, gypsum retarder 0.05-0.13 part, cream dispersant 0.05-0.1 part, fumed silica 0.1-0.5 part, hydroxypropyl 0.1-0.2 parts of methyl cellulose ether; the average particle diameter of the vitrified microspheres is 70-120 mesh. The high-strength plastic water-resistant gypsum decorative material provided by this application has small shrinkage, adjustable opening time for construction, high thixotropy, good adhesion, good water resistance, no foaming, no cracking, no powder falling after immersion, and high strength. .

Owner:苏州大乘环保新材有限公司

A kind of acrylate glue used for bonding the reinforcing ribs of the roof panel of the motor vehicle

ActiveCN106590447BDense cross-linked interpenetrating structureIncreased shear strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesParaffin waxBenzoyl peroxide

The invention discloses an acrylic glue used for bonding the roof reinforcement rib of a motor vehicle, and relates to the field of acrylic structural glue. The acrylic glue includes 1 part of oxidizing agent and 7 to 15 parts of reducing agent in parts by volume; parts by mass, The oxidizing agent includes 30-50 parts of dibutyl phthalate, 1-5 parts of bisphenol A epoxy resin, 15-20 parts of high rubber powder, 10-20 parts of benzoyl peroxide and 1-5 parts of Castor oil; in parts by mass, the reducing agent includes 20 to 54 parts of methyl methacrylate, 10 to 20 parts of impact modifier, 10 to 15 parts of chlorosulfonated polyethylene, and 1 to 3 parts of triethylenediamine , 0.5-1 part of paraffin, 1-5 parts of acrylic acid, 0.3-1 part of stabilizer, 1.2-1.6 parts of organically modified bentonite. The acrylic glue of the present invention can be closely connected with the adhesive under high-frequency vibration state, and does not fall off after long-term use.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

Method for producing ceramic tile bonding mortar by using black casting sand

The invention provides a method for producing ceramic tile bonding mortar by using black casting sand. The method comprises the following steps: crushing the agglomerated black casting sand into sandgranules through a crusher, then removing iron through a magnetic separator, then sending the iron-removed sand granules to a high-frequency vibrator so as to remove adhesive films on the surface of the black casting sand granules, sending the black casting sand obtained in the previous step to a drum screen for screening so as to select black casting sand fine powder, black casting sand fine sandand black casting sand medium sand, mixing, in parts by weight, the black casting sand fine powder, a mineral activator, redispersible emulsion powder, hydroxyethyl methyl cellulose and a polycarboxylic acid superplasticizer at a ratio, performing uniform stirring, then transferring the mixture into a grinding device for activation and grinding so as to obtain ceramic tile adhesive additives, mixing, in parts by weight, the ceramic tile adhesive additives, cement and the black casting sand fine sand at a ratio, and performing even stirring so as to obtain the ceramic tile bonding mortar. Theblack casting sand has complete utilization, is applied to production of the ceramic tile bonding mortar, and has significant economic, environmental and social benefits.

Owner:厦门兑泰新材料科技有限公司

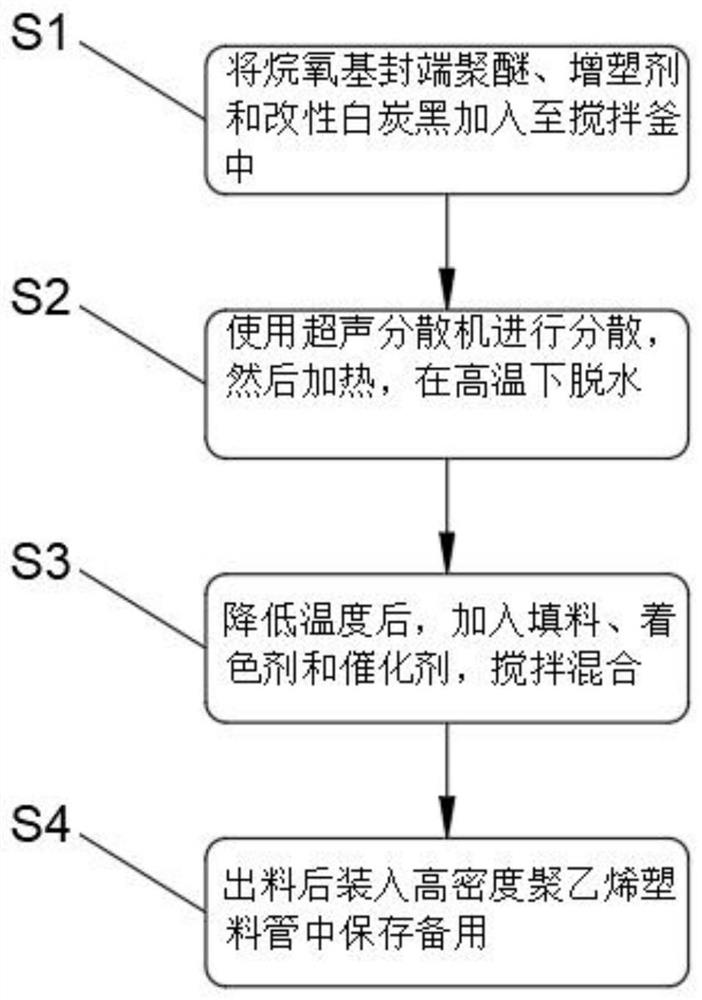

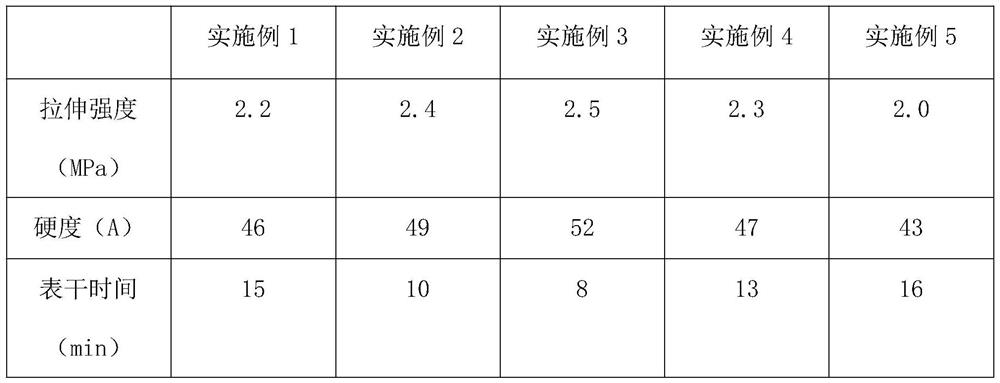

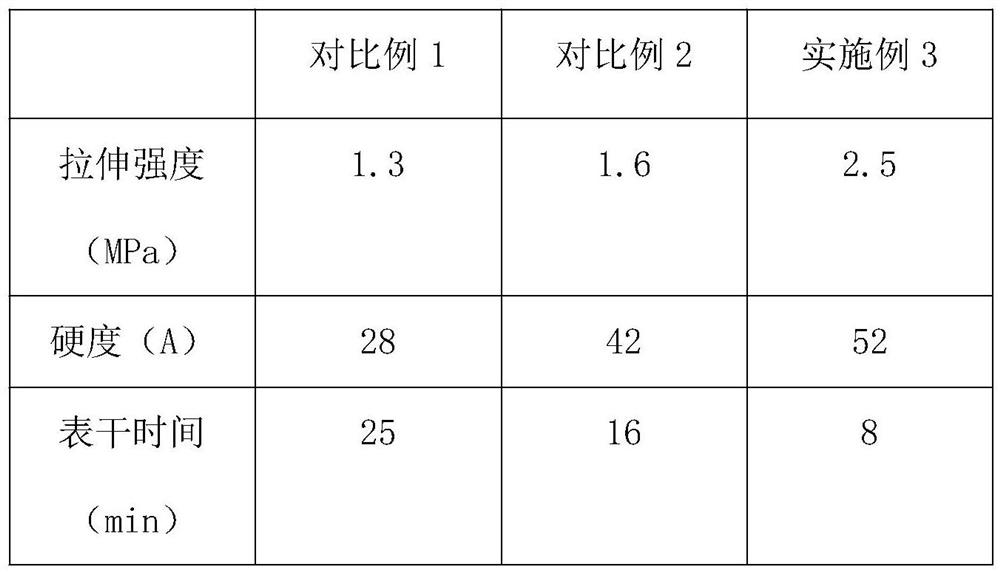

Preparation of multifunctional sealant for optical lamination

PendingCN112680164AHigh tensile strengthImprove appearance performanceNon-macromolecular adhesive additivesOther chemical processesChemistryCarbon black

The invention relates to the technical field of multifunctional sealants, in particular to preparation of a multifunctional sealant for optical bonding. The multifunctional sealant comprises alkoxy-terminated polyether, a plasticizer, a filler, modified white carbon black, a coloring agent and a catalyst, and in the preparation of the multifunctional sealant for optical lamination, alkoxy-terminated polyether adhesive which is high in thixotropy, low in hardness, adjustable in curing rate and high in strength is used as the multifunctional sealant for optical lamination box dam-sealing, and different performances of the sealant can be further improved; Addition of the colorant facilitates the color modulation of the sealant, effectively improves the tensile strength, elongation, shear strength, hardness and droop resistance of the sealant, improves the appearance performances, and allows fumed silica to have good reinforcing property, thixotropy and thickening property, so the fumed silica has good adhesion to the sealant along with increase of the use amount of the fumed silica, and the sealant has increased viscosity and excellent thixotropy.

Owner:苏州添易朗科技有限公司

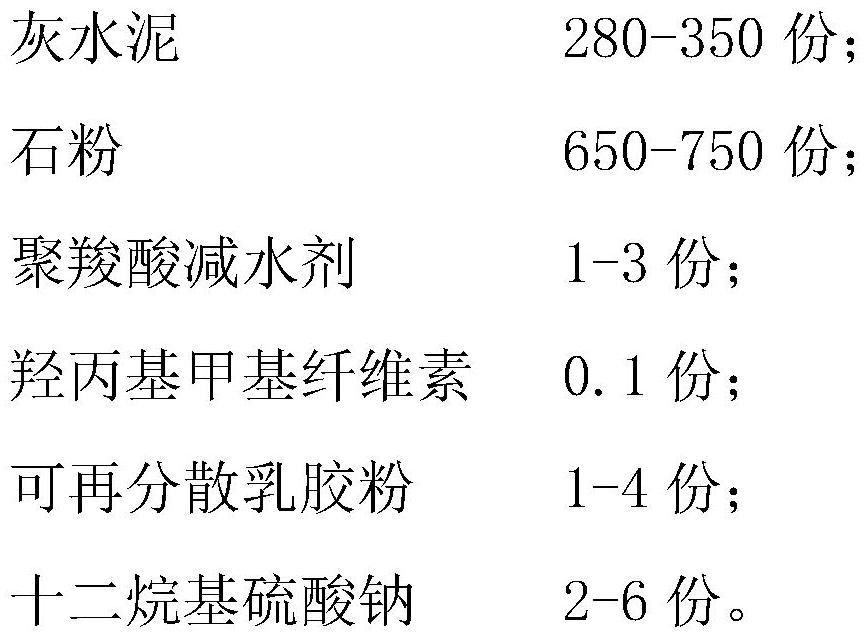

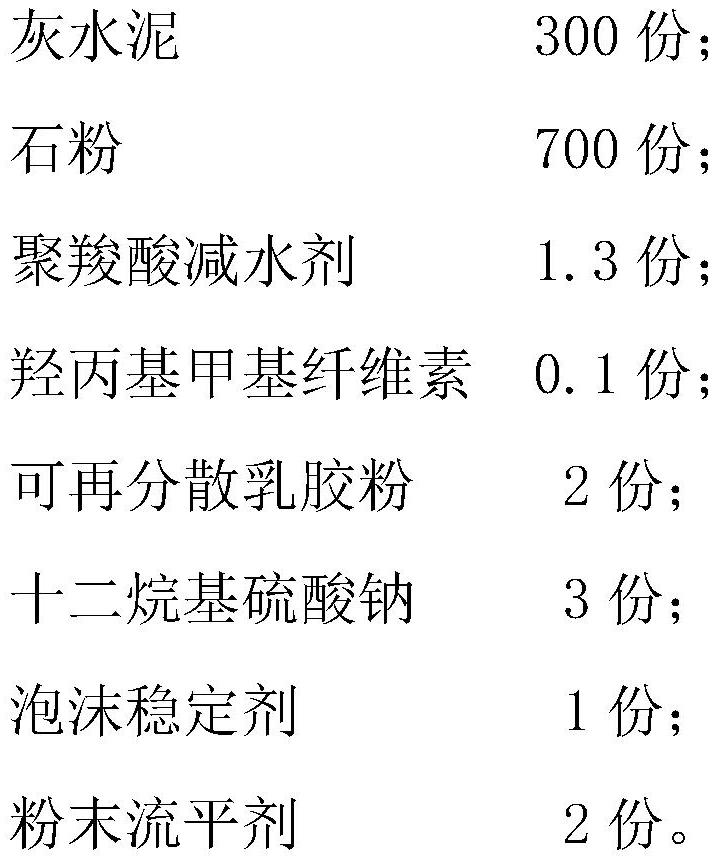

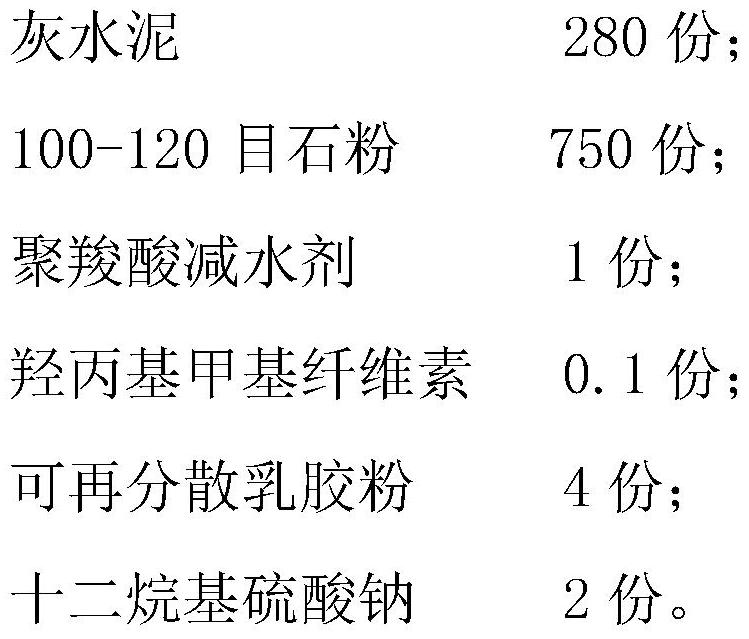

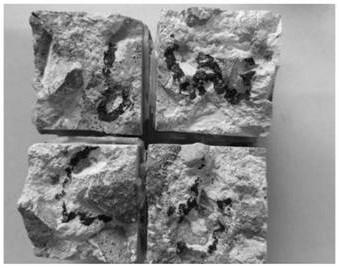

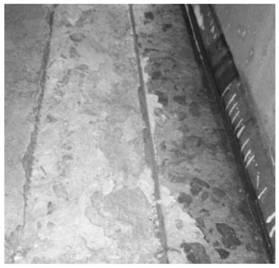

A kind of thermal insulation and sound insulation concrete and its preparation method and construction method

ActiveCN111960856BEnable recyclingLow densityCovering/liningsRoof covering using sealantsCelluloseThermal insulation

The invention discloses a thermal insulation concrete and a preparation method thereof. The preparation method comprises: first weighing gray cement, stone powder, polycarboxylate water reducer, hydroxypropyl methylcellulose, redispersible latex powder, twelve Alkyl sodium sulfate, foam stabilizer, foam leveling agent; each component is put into a powder machine in turn, stirred evenly, and then packaged in separate bags to obtain the heat-insulating and sound-insulating concrete. Using stone powder as the raw material of concrete to replace part of the cement can not only realize the recycling and reuse of stone powder, reduce environmental pollution, but also reduce the cost of thermal insulation and sound insulation concrete as a whole. At the same time, mixing stone powder with foaming agent sodium lauryl sulfate and other components can be directly carried out after mixing with water. The construction efficiency is high. The prepared concrete is easy to form a large number of uniform closed pores, and the opening rate is generally below 13%. Thereby, the thermal insulation, sound insulation, heat insulation and other properties of concrete can be greatly improved, and the density of concrete can also be reduced.

Owner:陈谓清

A low-temperature repair material for high-speed rail base concrete in severe cold areas and its application

The invention belongs to the technical field of construction materials, and particularly relates to a low-temperature repairing material for a high-speed rail base concrete in a severe cold region and application of the concrete low-temperature repairing material. The low-temperature repairing material comprises the following components: 425 ordinary Portland cement, 425 sulphoaluminate cement, 725 sulphoaluminate cement, a waterproof admixture, rubber powder, an aggregate, a water reducer, a construction improver, a water-retaining agent, an early strength agent, a nano multifunctional water repellent agent, and PP (polypropylene) fiber. The low-temperature repairing material for the high-speed rail base concrete in the severe cold region, provided by the invention, has a repairing construction time meeting a skylight time requirement of a high-speed rail, has compression strength after completion of hydration matching with that of the base concrete, is high in tensile bond strength with the base concrete, is slightly expanded and strong in anti-freezing circulation capability at -40 DEG C, can avoid secondary detachment, and well meets requirements on the low-temperature repairing material for the high-speed rail base concrete in the severe cold region.

Owner:郑州筑邦建材有限公司 +1

A kind of method of using black foundry sand to produce ceramic tile bonding mortar

The invention provides a method for producing ceramic tile bonding mortar by using black casting sand, comprising the following steps: using a crusher to break the agglomerated black casting sand into sand grains, and then removing iron through a magnetic separator, and then sending it into high Frequency vibrating machine removes the adhesive film on the surface of the black casting sand particles; the black casting sand obtained in step S1 is sent to the drum sieve for screening, and the black casting sand fine powder, black casting sand fine sand and black casting sand medium sand are separated ; Mix black casting sand fine powder, mineral activator, redispersible latex powder, hydroxyethyl methylcellulose, polycarboxylate superplasticizer in proportion and stir evenly according to parts by weight, and then transfer them to the grinding equipment for activation Grinding to prepare the ceramic tile adhesive additive; mixing the ceramic tile adhesive additive, cement, and black casting sand and fine sand in proportion according to parts by weight and stirring evenly to prepare tile adhesive mortar. The black casting sand of the invention can be fully utilized and applied to the production of ceramic tile adhesive mortar, and has remarkable economic, environmental and social benefits.

Owner:厦门兑泰新材料科技有限公司

A kind of thixotropic two-component silicone rubber foam sealant, preparation method and application thereof

ActiveCN110564361BLow viscosityHigh thixotropyNon-macromolecular adhesive additivesOther chemical processesPolymer scienceFoaming agent

The present invention provides a thixotropic two-component silicone rubber foam sealant, which is characterized in that it includes component A and component B, and the ratio of component A and component B is A:B=0.5~5:1 The mass ratio is mixed; wherein, the A component includes by weight: 100 parts of liquid silicone rubber, 0.5-5 parts of foaming agent, 1-5 parts of thixotropic agent, 15-35 parts of flame retardant, and 0.25-5 parts of catalyst 2 parts; wherein, the B component includes by weight: 100 parts of liquid silicone rubber, 15-25 parts of reinforcing agent, 1-5 parts of cross-linking agent, and 0.5-2 parts of inhibitor.

Owner:浙江清优材料科技有限公司

A kind of machine-sprayed plaster plaster mortar and its preparation process

ActiveCN104961423BSolve the problems that cannot meet the needs of mechanized constructionReduce dosageBond strengthConstruction aggregate

Owner:新疆荣高鸿骏新材料技术有限公司

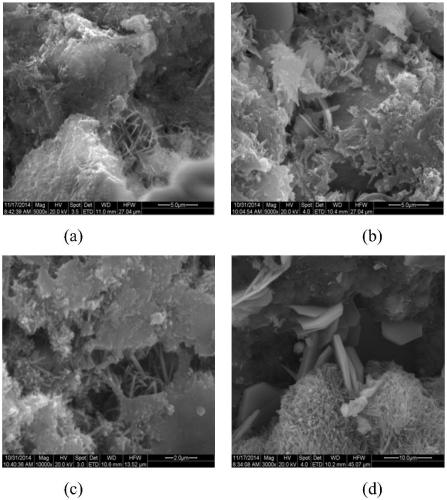

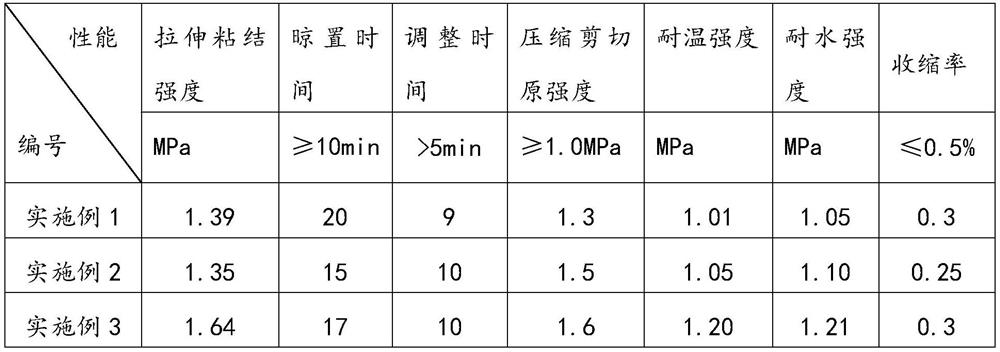

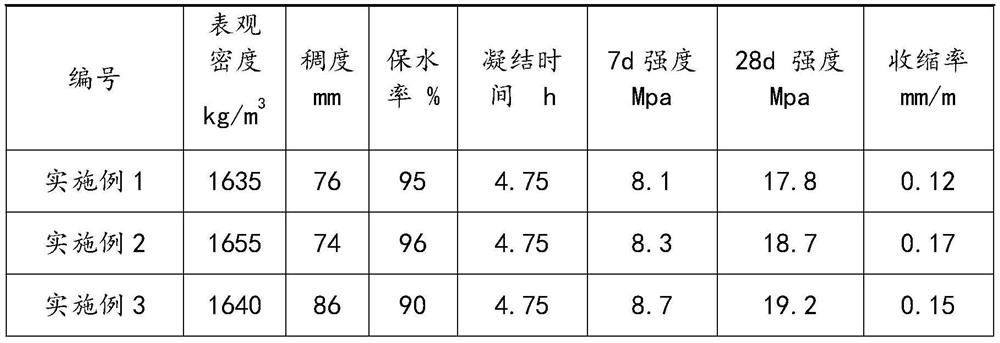

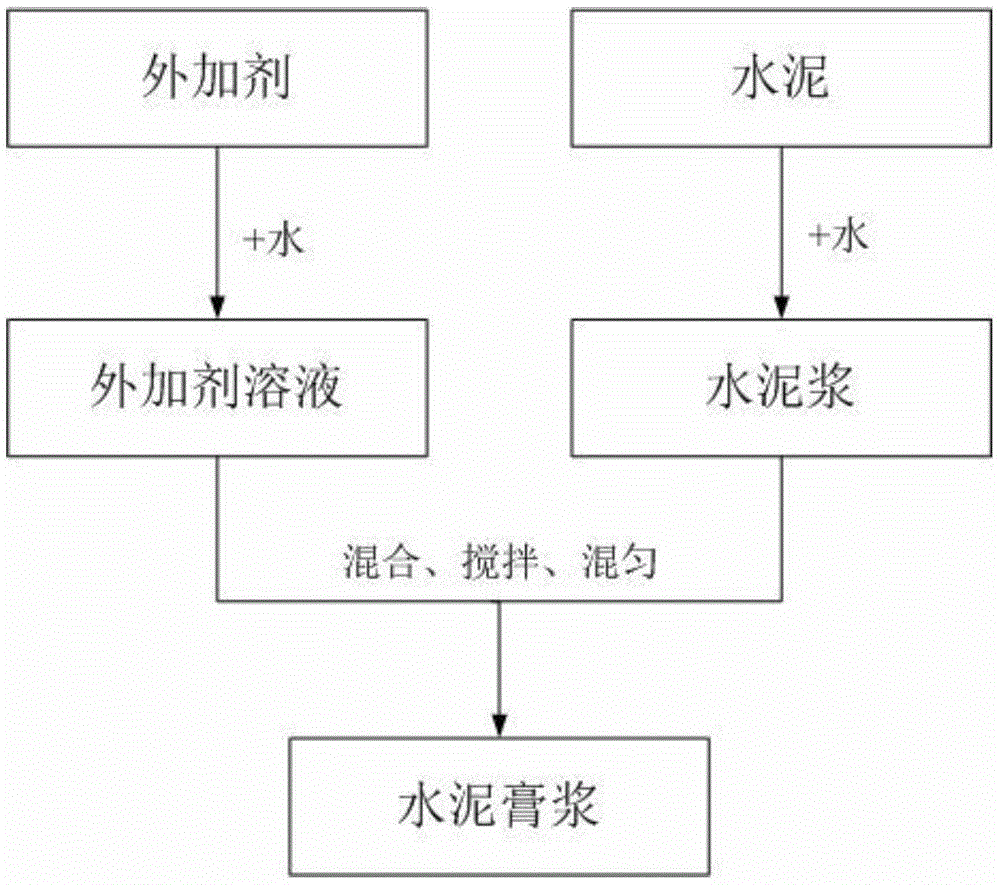

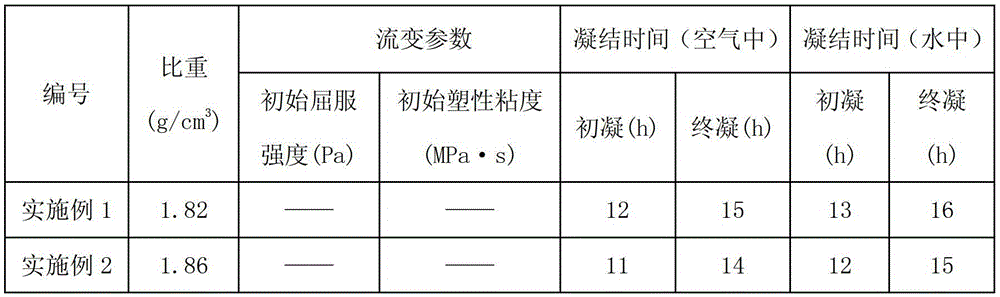

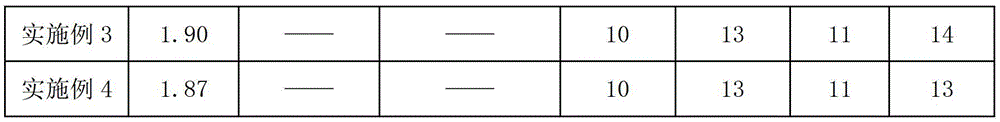

A kind of cement paste and preparation method thereof

The invention discloses cement paste comprising cement, water and an admixture, wherein the admixture comprises a biogum tackifier and a polycarboxylate superplasticizer. The invention simultaneously discloses a preparation method of the cement paste. The method comprises the following processing steps of: 1) adding and dissolving the admixture containing the iogum tackifier and the polycarboxylate superplasticizer in the first batch of water, so as to form an admixture solution; 2) mixing the cement with second batch of water, and agitating, so as to prepare cement slurry; 3) mixing the cement slurry with the admixture solution, agitating and evenly mixing to obtain the cement paste. The cement paste disclosed by the invention has excellent performances of high thixotropy and water resistance, and is suitable for grouting in macropore stratums such as karst holes, wide fissures of rock mass and rockfills.

Owner:SINOHYDRO FOUND ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com