A kind of thermal insulation and sound insulation concrete and its preparation method and construction method

A technology of thermal insulation, sound insulation and concrete, which is applied in the field of building materials, can solve the problems of affecting the thermal insulation performance of concrete foam bricks, the inability to carry out on-site pouring construction, and increasing construction costs, so as to increase thixotropy and sag resistance, improve plasticity and water retention Sexuality, enhanced water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method for thermal insulation and sound insulation concrete, comprising the following steps:

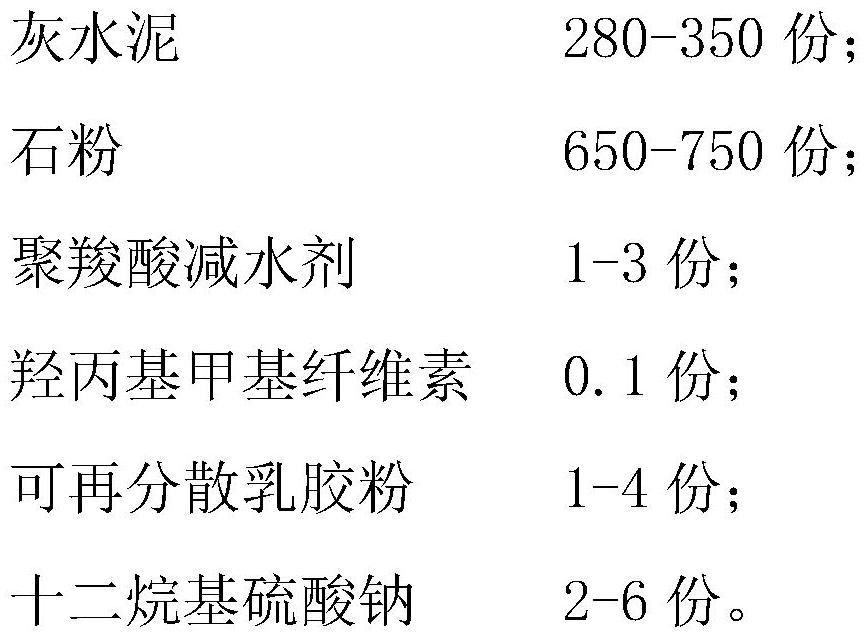

[0042] 1) First weigh each component by the following parts by weight:

[0043]

[0044] 2) Put each component into a powder machine in turn, stir evenly, and then pack in separate bags to obtain the heat-insulating and sound-insulating concrete.

Embodiment 2

[0046] A preparation method for thermal insulation and sound insulation concrete, comprising the following steps:

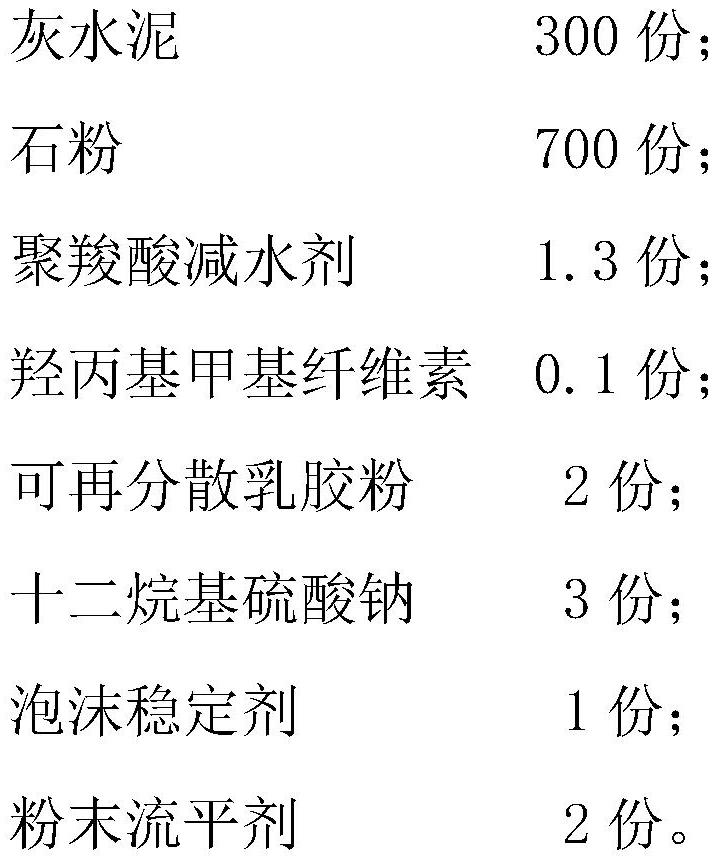

[0047] 1) First weigh each component by the following parts by weight:

[0048]

[0049] 2) Put each component into a powder machine in turn, stir evenly, and then pack in separate bags to obtain the heat-insulating and sound-insulating concrete.

Embodiment 3

[0051] A preparation method for thermal insulation and sound insulation concrete, comprising the following steps:

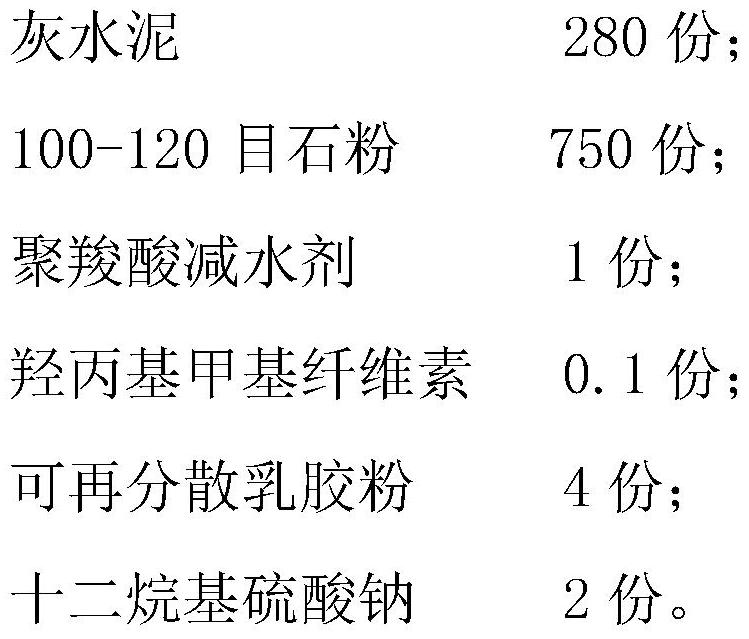

[0052] 1) First weigh each component by the following parts by weight:

[0053]

[0054] The foam stabilizer is polyoxyethylene alkanolamide.

[0055] 2) Put each component into a powder machine in turn, stir evenly, and then pack in separate bags to obtain the heat-insulating and sound-insulating concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com