A kind of cement paste and preparation method thereof

A technology of cement slurry and cement, applied in the field of cement paste and its preparation, can solve the problems of increased complexity, difficulty in achieving the purpose of plugging, large plasticity, etc., and achieve the effect of reduced complexity and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

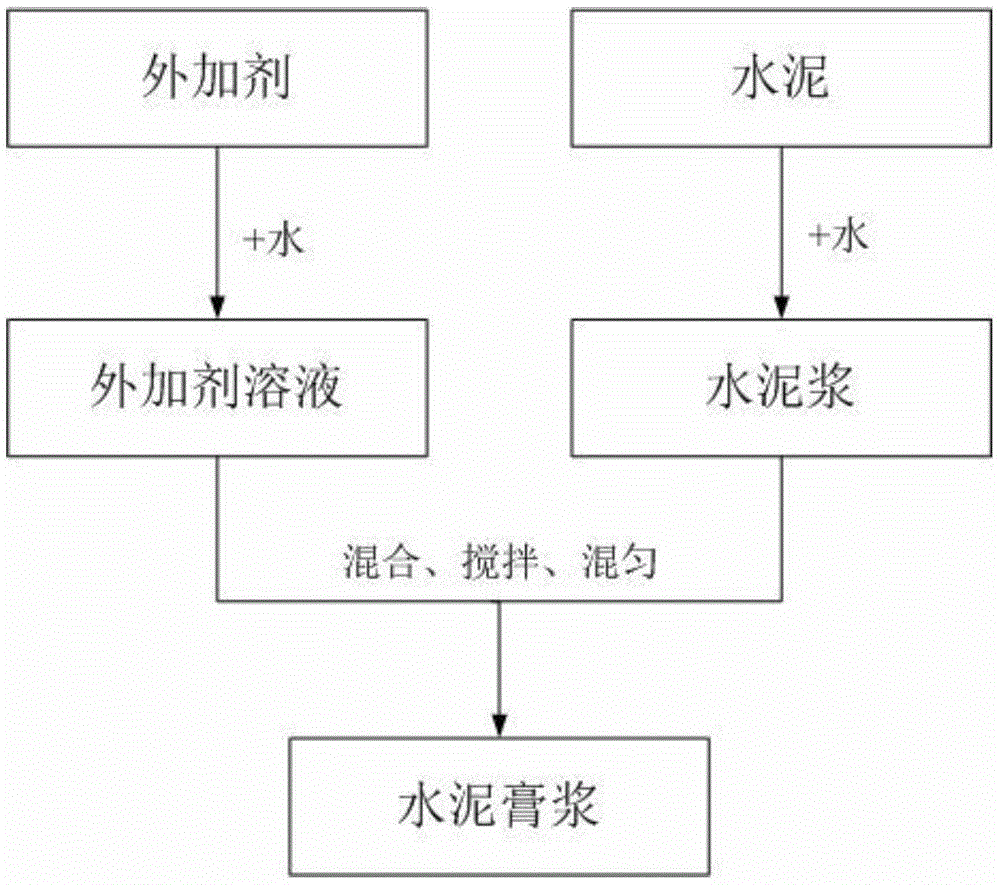

Method used

Image

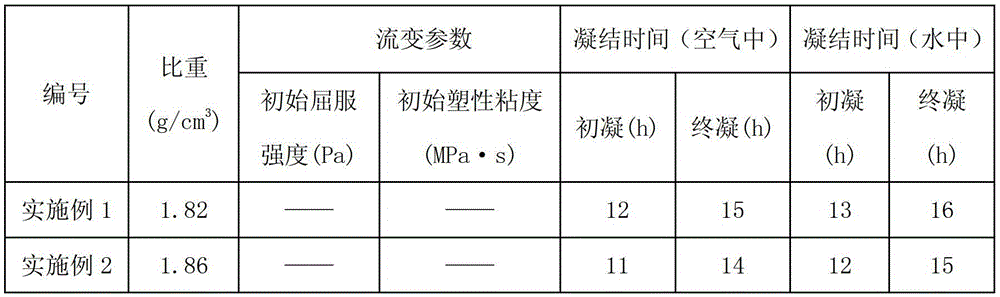

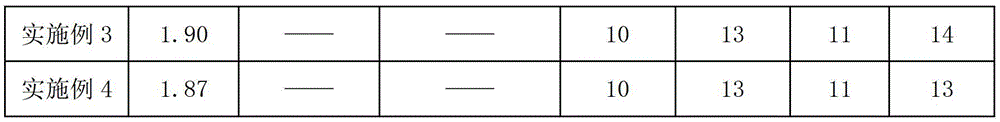

Examples

Embodiment 1

[0024] 1. Equipment, raw materials and process

[0025] Equipment: conventional double barrel mixer and 3SNS pump;

[0026] Raw materials: additives (composed of xanthan gum tackifier and polycarboxylate superplasticizer); water; cement;

[0027] Process: pure pressure type or orifice circulation type, the grouting process does not need to be adjusted.

[0028] 2. Preparation method

[0029] 1) Dissolve a bag of 0.2kg of admixture (composed of xanthan gum tackifier and polycarboxylate superplasticizer) in 10L of water to form an admixture solution, and then add it to the lower barrel of the double-barrel low-speed mixer;

[0030] 2) Mix and stir cement and water with a water-cement ratio of 0.45:1 to prepare 180L of cement slurry and put it into the upper barrel of a double-barrel low-speed mixer; or prepare pure water with a water-cement ratio of 0.45:1 Put 180L of mud into the upper barrel of the double-barrel low-speed mixer;

[0031] 3) Turn on the mixer, add the 180L ...

Embodiment 2

[0034] 1. Equipment, raw materials and process

[0035] Equipment: conventional double barrel mixer and 3SNS pump;

[0036] Raw materials: admixture (composed of welan gum tackifier and polycarboxylate superplasticizer); water; cement;

[0037] Process: pure pressure type or orifice circulation type, the grouting process does not need to be adjusted.

[0038] 2. Preparation method

[0039] 1) Dissolve a bag of 0.4kg of admixture (composed of welan gum tackifier and polycarboxylate superplasticizer) in 10L of water to form an admixture solution, and then add it to the lower barrel of the double-barrel low-speed mixer;

[0040] 2) Mix and stir cement and water with a water-cement ratio of 0.5:1 to prepare 170L of cement slurry and put it into the upper barrel of a double-barrel low-speed mixer; or prepare pure water with a water-cement ratio of 0.5:1 Put 170L of mud into the upper barrel of the double-barrel low-speed mixer;

[0041] 3) Turn on the mixer, add the 170L cement...

Embodiment 3

[0044] 1. Equipment, raw materials and process

[0045] Equipment: conventional double barrel mixer and 3SNS pump;

[0046] Raw materials: additives (composed of xanthan gum tackifier, welan gum tackifier and polycarboxylate superplasticizer); water; cement;

[0047] Process: pure pressure type or orifice circulation type, the grouting process does not need to be adjusted.

[0048] 2. Preparation method

[0049] 1) Dissolve a bag of 0.8kg admixture (consisting of xanthan gum tackifier, welan gum tackifier and polycarboxylate superplasticizer) in 10L of water to form an admixture solution, and then add it to the double barrel at low speed in the lower barrel of the mixer;

[0050] 2) Mix and stir cement and water with a water-cement ratio of 0.45:1 to prepare 190L of cement slurry and put it into the upper barrel of a double-barrel low-speed mixer; or prepare pure water with a water-cement ratio of 0.45:1 Put 190L of mud into the upper barrel of the double-barrel low-speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com