Method for producing ceramic tile bonding mortar by using black casting sand

A technology of bonding mortar and casting sand, which is applied in the field of building materials, can solve the problems that are difficult to get perfect use, slump and bleeding speed are accelerated, and the strength of concrete and mortar is reduced, so as to increase thixotropy Effects on sagging resistance, improving tensile bond strength, and reducing carbonization depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

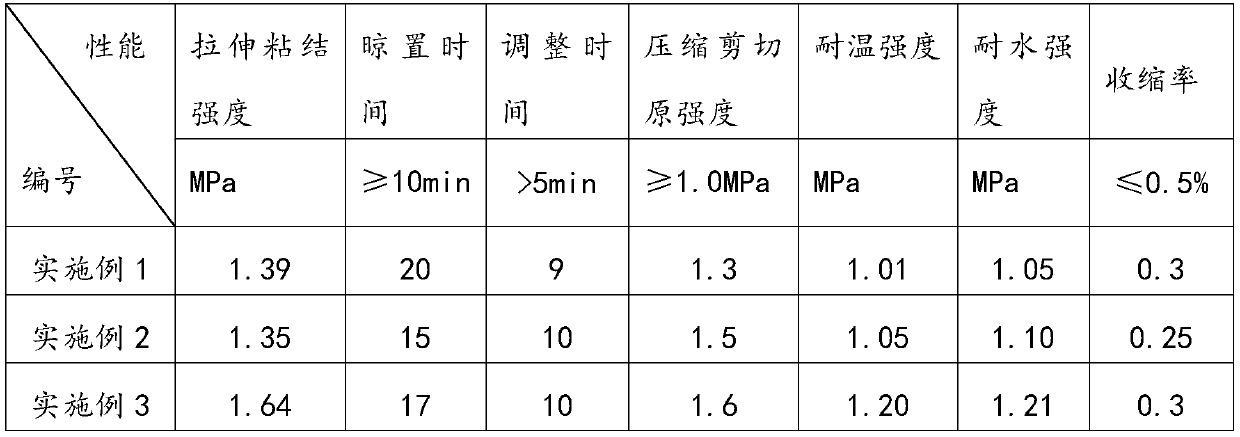

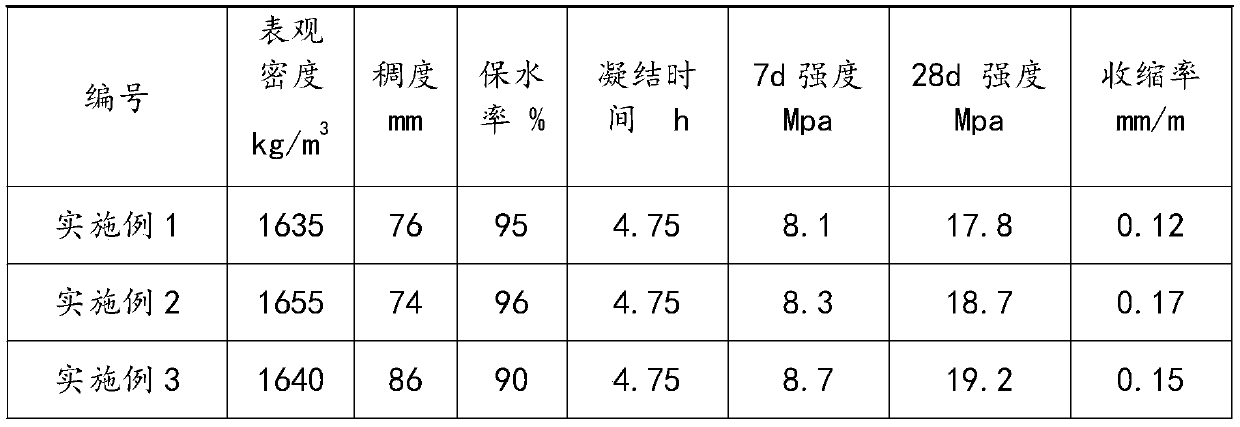

Embodiment 1

[0030] A method of utilizing black foundry sand to produce ceramic tile bonding mortar, comprising the following steps:

[0031] S1. Use a crusher to break the agglomerated black casting sand into sand grains, then remove iron through a magnetic separator, and then send it to a high-frequency vibrator to remove the film on the surface of the black casting sand particles;

[0032] S2. Send the black casting sand obtained through step S1 into the trommel sieve for screening, and select the black casting sand with a particle size of ≤0.08mm as black casting sand fine powder, and the black casting sand with a particle size of 0.08mm 0.6mm is used as black foundry sand medium sand;

[0033] Specifically, 40-43 wt% of sand in black foundry sand, 52-55 wt% of black foundry sand fine sand, and 3-5 wt% of black foundry sand fine powder.

[0034] S3, 80 parts by weight of black foundry sand fine powder obtained by sieving in step S2, 3.5 parts of mineral activator, 15 parts of redispers...

Embodiment 2

[0039] A method of utilizing black foundry sand to produce ceramic tile bonding mortar, comprising the following steps:

[0040] S1. Use a crusher to break the agglomerated black casting sand into sand grains, then remove iron through a magnetic separator, and then send it to a high-frequency vibrator to remove the film on the surface of the black casting sand particles;

[0041] S2. Send the black casting sand obtained through step S1 into the trommel sieve for screening, and select the black casting sand with a particle size of ≤0.08mm as black casting sand fine powder, and the black casting sand with a particle size of 0.08mm 0.6mm is used as black foundry sand medium sand;

[0042]Specifically, 40-43 wt% of sand in black foundry sand, 52-55 wt% of black foundry sand fine sand, and 3-5 wt% of black foundry sand fine powder.

[0043] S3, in parts by weight, 75 parts of black casting sand fine powder, 3 parts of mineral activator, 12 parts of redispersible latex powder, 0.1 p...

Embodiment 3

[0048] A method of utilizing black foundry sand to produce ceramic tile bonding mortar, comprising the following steps:

[0049] S1. Use a crusher to break the agglomerated black casting sand into sand grains, then remove iron through a magnetic separator, and then send it to a high-frequency vibrator to remove the film on the surface of the black casting sand particles;

[0050] S2. Send the black casting sand obtained through step S1 into the trommel sieve for screening, and select the black casting sand with a particle size of ≤0.08mm as black casting sand fine powder, and the black casting sand with a particle size of 0.08mm 0.6mm is used as black foundry sand medium sand;

[0051] Specifically, 40-43 wt% of sand in black foundry sand, 52-55 wt% of black foundry sand fine sand, and 3-5 wt% of black foundry sand fine powder.

[0052] S3, in parts by weight, 85 parts of black foundry sand fine powder, 5 parts of mineral activator, 18 parts of redispersible latex powder, 0.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com