Preparation of multifunctional sealant for optical lamination

A multi-functional, sealant technology, used in adhesives, adhesive types, polyether adhesives, etc., can solve the problems of occupying area, uncured strength of dam glue, insufficient water-adhesive bonding strength, etc. The effect of improving tensile strength and appearance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

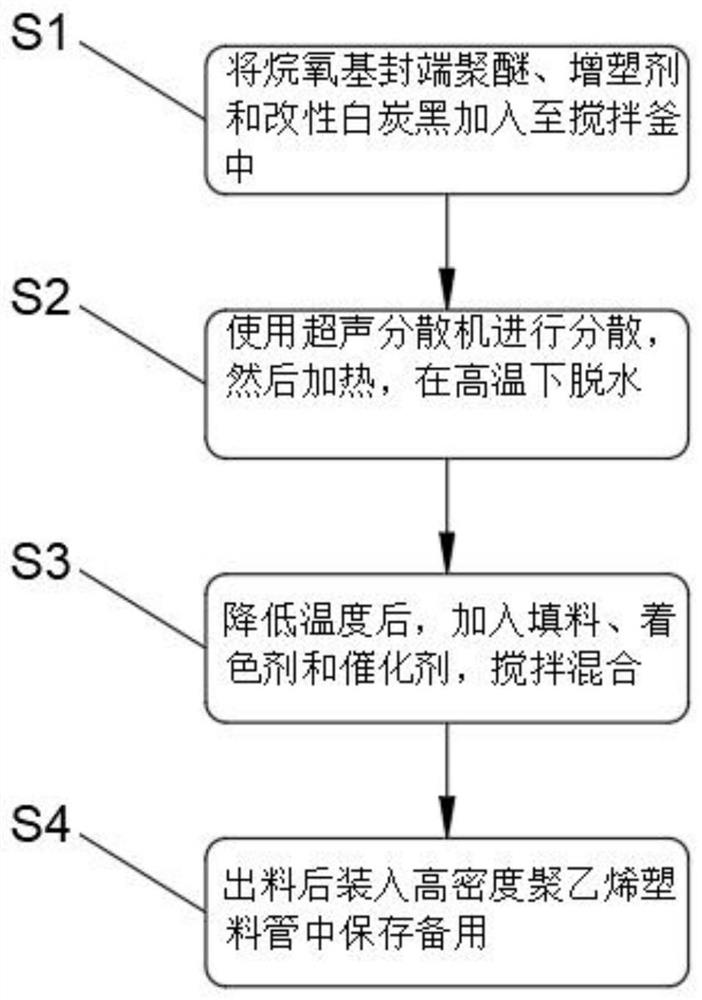

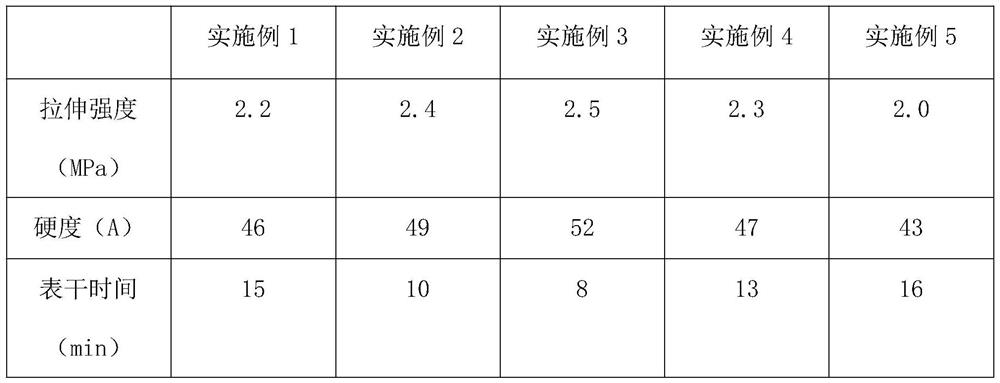

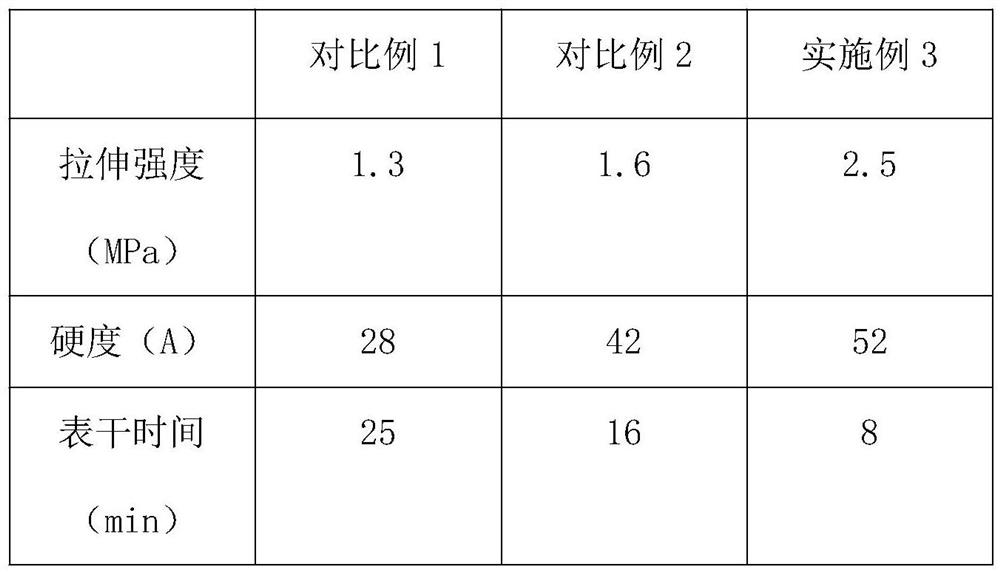

[0025] Embodiment 1 The preparation of a multifunctional sealant for optical bonding, comprising the following steps:

[0026] Add 95 parts of alkoxy-terminated polyether, 5 parts of plasticizer and 1 part of modified white carbon black into the stirring tank, use an ultrasonic disperser to disperse, then heat, the temperature is 80-110 °C, and the dehydration time is 2.5-4h, after lowering the temperature to 35-60°C, add 1 part of filler, 2 parts of coloring agent and 0.01 part of catalyst, stir and mix for 0.5-1h, put the material into a high-density polyethylene plastic tube and store it for later use.

Embodiment 2

[0027] Embodiment 2 The preparation of a multifunctional sealant for optical bonding, comprising the following steps:

[0028] Add 80 parts of alkoxy-terminated polyether, 9 parts of plasticizer and 5 parts of modified white carbon black into the stirring tank, use an ultrasonic disperser to disperse, and then heat at a temperature of 80-110°C for dehydration The time is 2.5-4h, after lowering the temperature to 35-60°C, add 7 parts of filler, 9 parts of coloring agent and 2 parts of catalyst, stir and mix for 0.5-1h, put the material into a high-density polyethylene plastic tube and store it for later use .

Embodiment 3

[0029] Embodiment 3 The preparation of a multifunctional sealant for optical bonding, comprising the following steps:

[0030] Add 70 parts of alkoxy-terminated polyether, 12.5 parts of plasticizer and 10 parts of modified white carbon black into the stirring tank, use an ultrasonic disperser to disperse, then heat, the temperature is 80-110 °C, and the dehydration time is 2.5-4h, after lowering the temperature to 35-60°C, add 13 parts of filler, 16 parts of coloring agent and 3 parts of catalyst, stir and mix for 0.5-1h, put the material into a high-density polyethylene plastic tube and store it for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com