High-temperature trip temperature heat-resistant coating

A technology of heat-resistant coatings and high-temperature belts, which is applied in the direction of anti-corrosion coatings, coatings, and metal material coating processes. Smooth and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

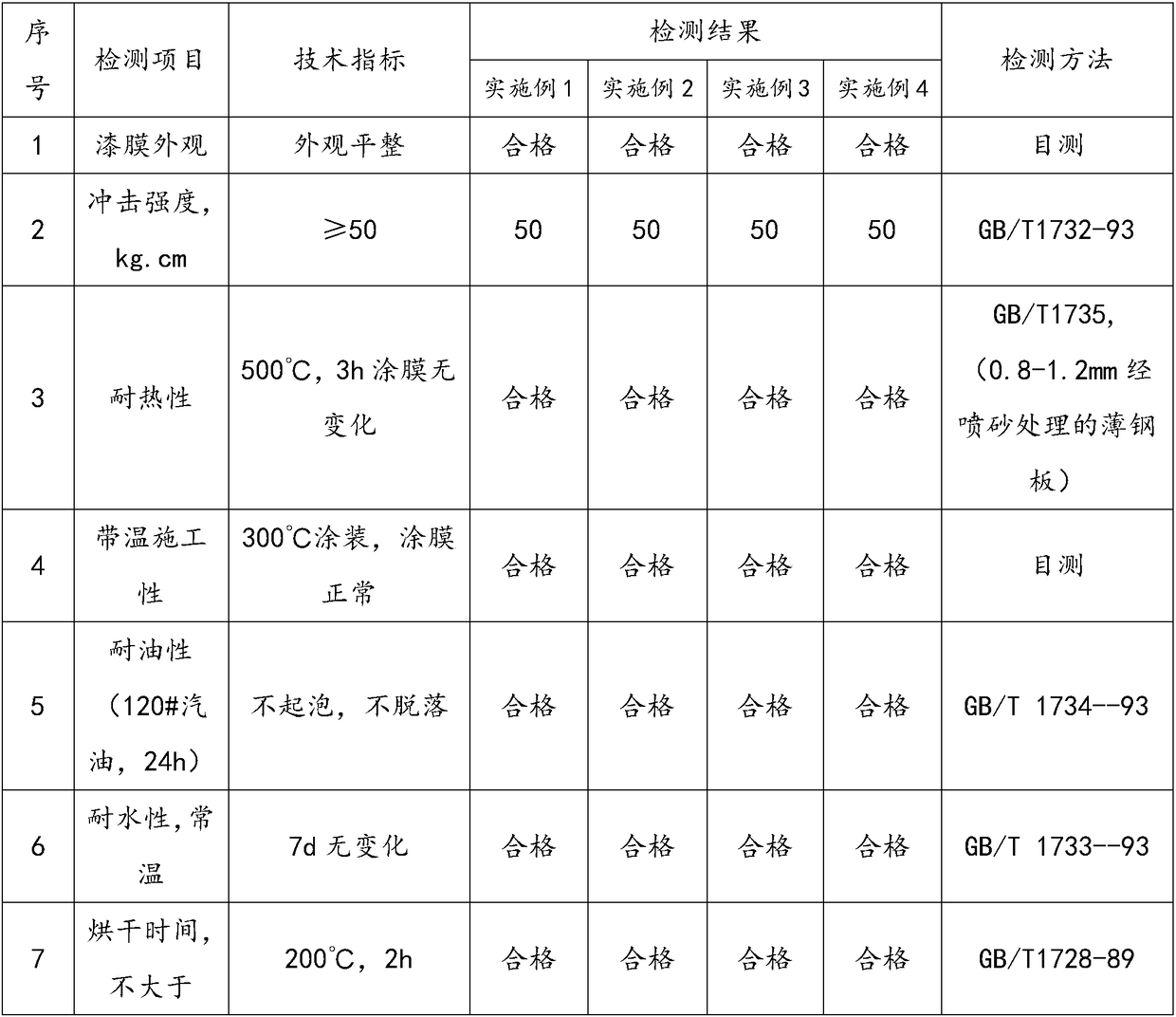

Examples

Embodiment 1

[0022] A heat-resistant coating with high temperature and temperature, its formula is as follows:

[0023] Component A: 15 parts of floating aluminum silver paste, 8 parts of barium sulfate, 10 parts of mica powder, 5 parts of zinc phosphate, 3 parts of aluminum tripolyphosphate, 0.5 parts of anti-settling agent, 1 part of thixotropic agent, modified silicone 50 parts of high polymer, 8 parts of diethylene glycol butyl ether, 0.2 part of defoamer;

[0024] Component B: 2.5 parts of dioctyl phthalate, 2 parts of diethylene glycol butyl ether.

[0025] Among them, the anti-settling agent is organic bentonite, the thixotropic agent is polyamide wax, the defoamer is polyether modified polysiloxane, and the modified silicone polymer is SM1053G.

Embodiment 2

[0027] A heat-resistant coating with high temperature and temperature, its formula is as follows:

[0028] Component A: 20 parts of floating aluminum silver paste, 15 parts of barium sulfate, 5 parts of mica powder, 4 parts of zinc phosphate, 8 parts of aluminum tripolyphosphate, 0.8 parts of anti-sedimentation agent, 0.5 parts of thixotropic agent, modified silicone 40 parts of high polymer, 9 parts of diethylene glycol butyl ether, 0.3 part of defoamer;

[0029] Component B: 2 parts of dioctyl phthalate, 3 parts of diethylene glycol butyl ether.

[0030] Among them, the anti-settling agent is fumed silica, the thixotropic agent is hydrogenated castor oil, the defoaming agent is polyester-modified polysiloxane, and the modified organosilicon polymer is SM1053G.

Embodiment 3

[0032] A heat-resistant coating with high temperature and temperature, its formula is as follows:

[0033] Component A: 30 parts of floating aluminum silver paste, 5 parts of barium sulfate, 8 parts of mica powder, 8 parts of zinc phosphate, 5 parts of aluminum tripolyphosphate, 1 part of anti-settling agent, 0.7 parts of thixotropic agent, modified organic 60 parts of silicon polymer, 15 parts of diethylene glycol butyl ether, 0.5 part of defoamer;

[0034] Component B contains the following components in parts by weight: 3 parts of dioctyl phthalate and 2.8 parts of diethylene glycol butyl ether.

[0035] Among them, the anti-settling agent is fumed silica, the thixotropic agent is polyamide wax, the defoamer is polyester-modified polysiloxane, and the modified organosilicon polymer is SM1053G.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com