An admixture for improving crack resistance and thixotropic performance of super high-rise pumped concrete

A technology of concrete and admixtures, which is applied in the field of building materials, can solve the problems of high amount of cementitious materials, easy occurrence of honeycomb, pitted surface and exposed ribs, and large temperature rise of concrete insulation, so as to improve the tensile strength and crack resistance , Reduce the risk of pipe plugging and construction difficulty, improve the effect of thixotropy and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The montmorillonite of more than 200 mesh sieves was selected, add deionized water, solid-liquid ratio of 1: 3, stir after 20 min, 15 min, to obtain montmorillonine suspension; 1 parts of polyvinylpyrrolidone to 3 parts In the acrylamide solution, the side droplets are stirred, and the mixture is prepared for a polymer solution after stirring 42min; the montmorillonine suspension and the polymer solution are allowed to stand for 12 h after 12 h, and the composite suspension is obtained; 30 to 40 nm in diameter; , The degreasing cotton fibers of 150 to 250 nm were submerged from 1% NaOH solution for 30 min, and then the solution pH of 9 was adjusted with glacial acetic acid, and then dried after pulling filtration using deionized water, soaking in the composite suspension for 30 min. Then drying in a dry box at 80 ° C to obtain modified montmorillonite.

[0037] The polypropylene of 20 parts of length 1 to 1.2 cm was subjected to 50 parts by weight of 10% sodium hydroxide so...

Embodiment 2

[0047] In this embodiment, the modified monmillplage preparation method is substantially the same as in Example 1, and the difference is: 35 parts of montmorillonite, 5 parts of polyacrylamide, 1 polyvinylpyrrolidone, and 10 degreased cotton fibers.

[0048] The microcrystalline cellulose modified high water absorbing resin fiber preparation method is basically the same as in Example 1, and the difference is: 95 parts of high water absorbent fibers, 40 parts of composite water absorbing resin powder, 0.04 parts of ethylene glycol dihydrate glycerol ether, concentration 20% Aluminum sulfate solution 0.05 parts.

[0049] 52 parts of silicon ash, 25 pieces of flour powder, 7 ultrafine limestone powder, 11 modified montmorillonite, 5 microfibrin modified high water absorption resin fibers to improve ultra-high-level pumping concrete Crack, thixotropic additives.

[0050] The improved ultra-high-layer pumping concrete cracked and thixotropped additives prepared by the present embodimen...

Embodiment 3

[0056] The modified montmorillonite and micrmorillonite and micrormorillonine modified high water absorption resin fibers were the same as in Example 2.

[0057] 49 parts of silicon ash, 29 powder coal ash micro-balls, 7 ultra-fine limestone powder, 10 modified montmorillonite, 5 crystalline cellulose modified high water absorption resin fibers to improve ultra-high-level pumping concrete resistance Crack, thixotropic additives.

[0058] The improved ultra-high-layer pumping concrete cracked and thixotropped additives were applied to C80 concrete, and the compatible ratio and related performance test results were shown in Table 5 and Table 6.

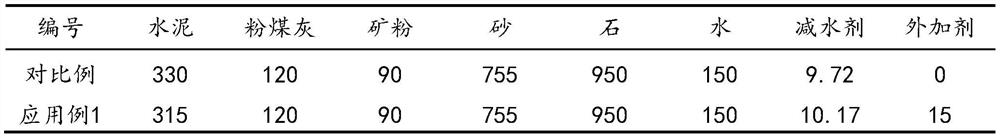

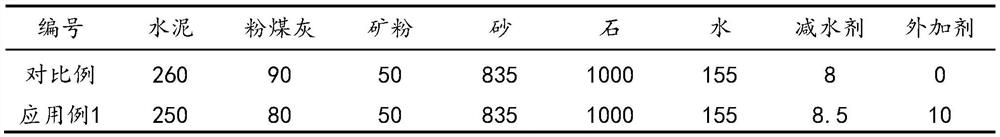

[0059] Table 5 Concrete mix ratio (kg / m 3 )

[0060]

[0061]

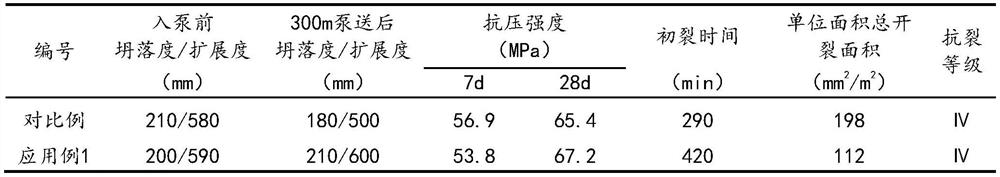

[0062] Table 6 Concrete Performance Test Results

[0063]

[0064] The above results show that the present invention improves the ultra-high-layer pumping concrete cracking, and the thixotropped additive is applied to concrete, and when the concrete is pumped to 300m an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com