Acrylate structural adhesive being resistant against solvent scrubbing

A technology of structural adhesives and acrylates, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve problems such as failure to pass high temperature and high humidity, and decrease in bonding strength. Achieve the effect of smooth glue, good adhesion and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

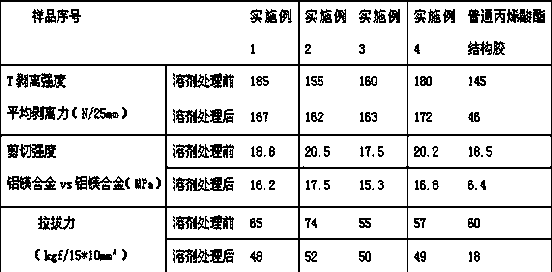

Examples

Embodiment 1

[0035] A component composition:

[0036] Ethoxylated bisphenol A dimethacrylate: 220 g

[0037] Methyl methacrylate: 280 g

[0038] Hydroxyethyl methacrylate: 120 g

[0039] Methacrylic acid: 100 g

[0040] 2-Hydroxyethyl methacrylate phosphate: 100 g

[0041] Vinyl-terminated nitrile rubber (VTBN): 140 g

[0042] MBS: 260g

[0043] Tetramethylthiourea: 80 g

[0044] N,N-Dimethyl-p-toluidine: 50 g

[0045] Hydroquinone: 8.5 g

[0046] Tetrasodium EDTA: 12 g

[0047] Vinyltris(2-methoxyethoxy)silane: 35 g

[0048] Composition of component B:

[0049] Benzoyl peroxide: 60 g

[0050] Cumene hydroperoxide: 35 g

[0051] E51: 180 g

[0052] Phthalates: 80 g

[0053] Silica powder: 30 g

[0054] Carbon black: 3.5 g

[0055] Concrete preparation steps are:

[0056] The preparation process of component A is to clean the reactor. First add 220g of ethoxylated bisphenol A dimethacrylate, 280g of methyl methacrylate, 120g of hydroxyethyl methacrylate, 100g of methacrylic ...

Embodiment 2

[0059] A component composition:

[0060] Tricyclodecane dimethanol diacrylate: 200 g

[0061] Tetrahydrofuryl methacrylate: 260 g

[0062] Hydroxyethyl methacrylate: 240 g

[0063] Methacrylic acid: 80 g

[0064] 2-Hydroxyethyl methacrylate phosphate: 60 g

[0065] Carboxy-terminated nitrile rubber (CTBN): 150 g

[0066] ABS: 300g

[0067] Vinylthiourea: 46 g

[0068] Aldehyde amine condensation product PDHP: 64 g

[0069] Triphenylphosphine: 15 g

[0070] p-tert-butylcatechol: 10 g

[0071] Tetrasodium EDTA: 12 g

[0072] γ-Mercaptopropyltrimethylsilane: 35 g

[0073] Composition of component B:

[0074] Lauroyl peroxide: 100 g

[0075] Cumene hydroperoxide: 30 g

[0076] E44: 140g

[0077] Parabens : 120 g

[0079] Fumed silicon: 25 g

[0080] Carbon black: 3.5 g

[0081] Concrete preparation steps are:

[0082] The preparation process of component A is to clean the reactor. First add 200 g of tricyclodecane dimethanol diacry...

Embodiment 3

[0085] A component composition:

[0086] Methyl methacrylate: 360 g

[0087] Tetrahydrofuryl methacrylate: 200 g

[0088] Hydroxypropyl methacrylate: 140 g

[0089] Methacrylic acid: 120 g

[0090] Polybutadiene rubber: 180 g

[0091] ABS: 140g

[0092] SBS: 260g

[0093] Diaminosulfonyl: 60 g

[0094] N,N-Dimethyl-p-toluidine: 70 g

[0095] Triphenylphosphine: 10 g

[0096] p-Naphthoquinone: 10 g

[0097] Tetrasodium EDTA: 14 g

[0098] γ-Mercaptopropyltriethylsilane: 40 g

[0099] Composition of component B:

[0100] Benzoyl peroxide: 130 g

[0101] E51: 60g

[0102] E44: 80g

[0103] Parabens : 100 g

[0105] Carbon black: 3.5 g

[0106] Concrete preparation steps are:

[0107] The preparation process of component A is to clean the reactor. First add 360g of methyl methacrylate, 200g of tetrahydrofuryl methacrylate, 140g of hydroxypropyl methacrylate, 120g of methacrylic acid, 180g of polybutadiene rubber, 140g of ABS, and 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com