Special ultrathin-layer masonry mortar for sintered building blocks made of regenerated fine powder containing red bricks

A technology for regenerating fine powder and masonry mortar, applied in the field of building materials, can solve the problems of reducing the thermal insulation effect of the wall, waste of raw materials, etc., and achieve the effect of significant ecological environment benefits, improving the strength of the mortar, and reducing the shrinkage and expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

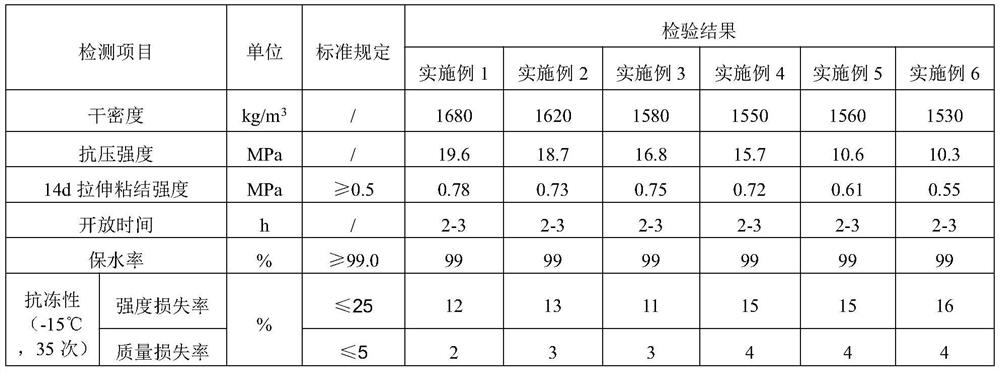

Examples

Embodiment 1

[0044] A special ultra-thin layer masonry mortar for sintered blocks made of recycled fine powder containing red brick, comprising the following components in parts by weight: 350 parts of cement, 195 parts of recycled fine powder containing red brick, 455 parts of fine sand 10 parts, 10 parts of redispersible latex powder, 1.5 parts of hydroxypropyl methylcellulose ether, 1.05 parts of water reducing agent, and 0.3 parts of wood fiber.

[0045] Among them, the mass percentage of 0.3mm<particle size≤0.6mm in the fine sand is 8%, the mass percentage of 0.15mm<particle size≤0.3mm is 82%, and the mass percentage of the particle size≤0.15mm is The percentage is 10%.

[0046] The preparation method of the regenerated fine powder containing red bricks is as follows: transport the construction waste containing red bricks classified and transported to the construction waste disposal site, and process the construction waste by using a mobile impact crusher and a screening machine. Deb...

Embodiment 2

[0055] A special ultra-thin layer masonry mortar for sintered blocks made of recycled fine powder containing red brick, comprising the following components in parts by weight: 350 parts of cement, 325 parts of recycled fine powder containing red brick, 325 parts of fine sand 10 parts, 10 parts of redispersible latex powder, 1.5 parts of hydroxypropyl methylcellulose ether, 1.05 parts of water reducing agent, and 0.3 parts of wood fiber.

[0056] Among them, the mass percentage of 0.3mm

[0057] The preparation method of the regenerated fine powder containing red brick is the same as in Example 1.

[0058] The obtained regenerated fine powder containing red brick with a particle size of 0-0.6 mm is subjected to sieve analysis for particle size gradation. Among them, in the regenerated fine powder co...

Embodiment 3

[0061] A special ultra-thin layer masonry mortar for sintered blocks made of recycled fine powder containing red brick, comprising the following components in parts by weight: 300 parts of cement, 210 parts of recycled fine powder containing red brick, 490 parts of fine sand 8 parts, 8 parts of redispersible latex powder, 1.5 parts of hydroxypropyl methylcellulose ether, 0.3 parts of water reducing agent, and 0.4 parts of wood fiber.

[0062] Among them, the mass percentage of 0.3mm

[0063] The preparation method of the regenerated fine powder containing red brick is the same as in Example 1.

[0064] The obtained regenerated fine powder containing red brick with a particle size of 0-0.6 mm is subjected to sieve analysis for particle size gradation. Among them, in the regenerated fine powder conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com